High-activation coal ash loaded nano catalytic material and synthetic process

A nano-catalytic material and nano-catalytic technology, which is applied in the field of preparation of highly activated fly ash-loaded nano-catalytic materials, can solve problems such as adding methods, unsatisfactory product dispersion, and inconspicuous catalytic effects, so as to improve the speed of material diffusion and The effect of interphase reaction speed, strength improvement and thermodynamic improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

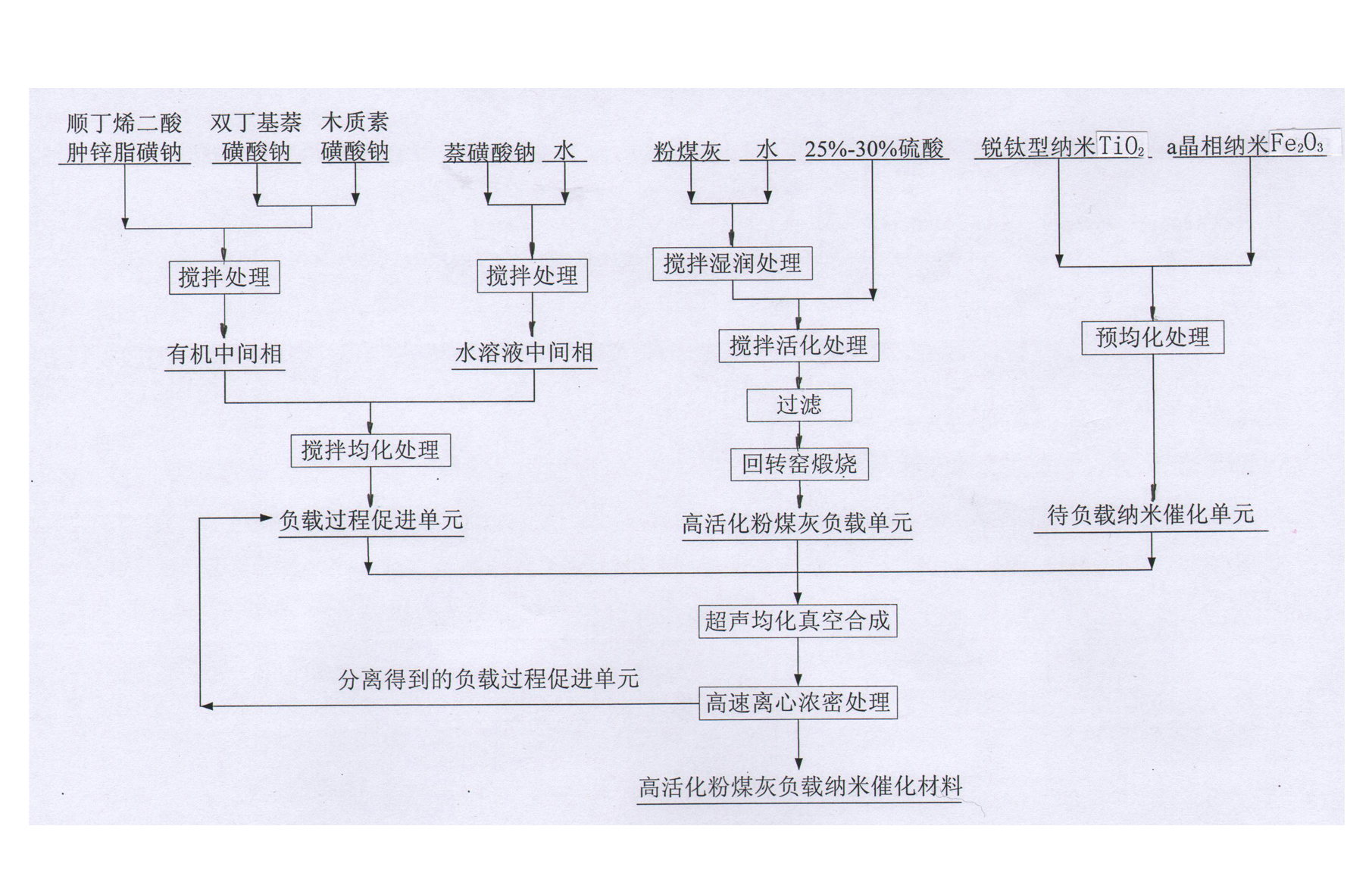

[0034] Preparation of precursor liquid phase environment

[0035] Add the loading process promotion unit into the ultrasonic homogenization vacuum synthesis kettle, and start the stirring at the same time for pre-homogenization treatment for 10-20 minutes, and the stirring Reynolds number is 20000-30000;

[0036] Add the highly activated fly ash load unit into the kettle, and the time for adding is 10-20min. After the addition, continue to stir for 10-20min, and the stirring Reynolds number is 20000-30000;

[0037] Add the nano catalytic unit to be loaded into the kettle, and the addition takes 10-20 minutes. After the addition is completed, stop stirring, and at the same time turn on the ultrasonic homogenization device, the ultrasonic frequency is 20-25kHz, and stop after ultrasonic treatment for 20-30 minutes. Then turn on the vacuum pump until the absolute pressure in the kettle drops to 0.02-0.03MPa, and continue the treatment under this negative pressure for 90-180min to...

Embodiment

[0041] (1) Put 280kg of di-sec-octyl sulfonate maleate in a high-speed stirring tank, the stirring Reynolds number is 20000-30000, and add 200kg of sodium dibutylnaphthalene sulfonate and the dispersion material lignin sulfonate into the tank 120kg of sodium bicarbonate, the feeding speed is 32kg / min, after the feeding is finished, the stirring intensity is kept constant and the stirring process is continued for 30min to obtain the organic mesophase.

[0042] Introduce 120kg of deionized water into the empty kettle, stir at a low speed, and the stirring Reynolds number is 5000-10000. After heating up to 45-55°C, add 80kg of sodium naphthalenesulfonate into the kettle at a rate of 16kg / min, and continue stirring until the naphthalenesulfonate Sodium bicarbonate is completely dissolved in water, thereby preparing an aqueous solution mesophase.

[0043] Add the organic mesophase to the aqueous mesophase, keep stirring the Reynolds number of 20000-30000 during the addition process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com