Non-smoked, non-fried, non-carbonado and non-salt-boiled meat product processing method

A processing method and technology of meat products, which are applied in the four non-processing fields of livestock, poultry and aquatic products, to achieve the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

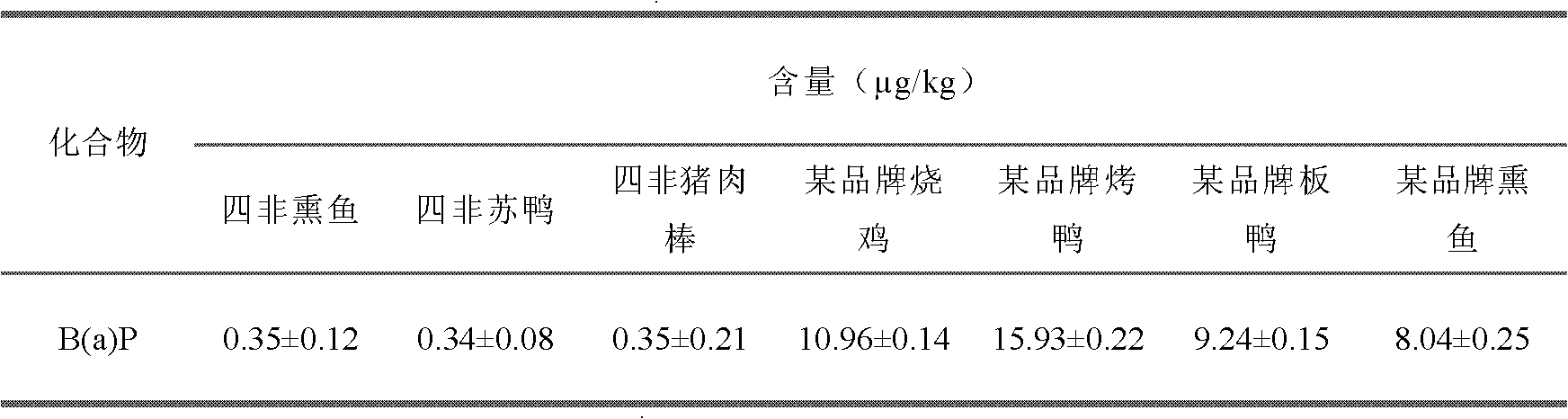

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

[0017] The preparation of embodiment 1 four non-smoked fish

[0018] 1. Preparation of flavor enhancer: D-glucose 5%, L-lysine 8%, thiamine 8%, D-xylose 7%, L-glutamic acid 6%, L-cysteine 10% %, 10% of L-alanine, 5% of hydrochloric acid, and 41% of distilled water are mixed, fully dissolved, and the pH value of the solution is adjusted to 7.0 with hydrochloric acid or sodium hydroxide to obtain a flavor enhancer.

[0019] 2. Preparation of incense: 1% guaiacol, trans, trans-2,4-heptadienal 2%, 4-methylguaiacol 6%, ethyl valerate 10%, 3 -Acetyl-2,5-dimethylfuran 3%, furfural 3%, ethyl butyrate 1%, 2-ethylpyrazine 5%, eugenol 3%, 4-vinylphenol 4%, 2, 5-Dimethyl-3-acetylfuran 2%, 2,3-dimethylpyrazine 3%, methyl eugenol 3%, 5-methylfurfural 3%, maltol 4%, acetic acid 15%, Mix 3% ethanol and 30% distilled water and dissolve it fully.

[0020] 3. Preparation of pickling solution: (per catty of water) 2.5g Angelica dahurica, 2.5g star anise, 2g cumin, 5g cinnamon, 2.5g ginger, 1...

Embodiment 2 4

[0027] The preparation of embodiment 2 four non-smoked fish

[0028] 1. Preparation of flavoring agent: D-glucose 2%, L-lysine 7%, thiamine 10%, D-xylose 6%, L-glutamic acid 7%, L-cysteine 8% %, 12% of L-alanine, 3% of hydrochloric acid and 45% of distilled water are mixed, fully dissolved, and the pH value of the solution is adjusted to 7.0 with hydrochloric acid or sodium hydroxide to obtain a flavor enhancer.

[0029] 2. Preparation of incense: 5% guaiacol, trans, trans-2,4-heptadienal 1%, 1% 4-methylguaiacol, 3% ethyl valerate, 3 -Acetyl-2,5-dimethylfuran 4%, furfural 4%, ethyl butyrate 1%, 2-ethylpyrazine 3%, eugenol 2%, 4-vinylphenol 8%, 2, 5-Dimethyl-3-acetylfuran 3%, 2,3-dimethylpyrazine 2%, methyl eugenol 7%, 5-methylfurfural 7%, maltol 5%, acetic acid 20%, Mix 2% ethanol and 32% distilled water and dissolve it fully.

[0030] 3. Preparation of pickling solution: (per catty of water) 3g Angelica dahurica, 3g star anise, 3g cumin, 4g cinnamon, 2g ginger, 2g pepper...

Embodiment 3 4

[0037] The preparation of embodiment 3 four non-smoked fish

[0038] 1. Preparation of flavor enhancer: D-glucose 9%, L-lysine 2%, thiamine 5%, D-xylose 5%, L-glutamic acid 9%, L-cysteine 15% %, 5% of L-alanine, 5% of hydrochloric acid, and 45% of distilled water are mixed, fully dissolved, and the pH value of the solution is adjusted to 7.0 with hydrochloric acid or sodium hydroxide to obtain a flavor enhancer.

[0039] 2. Preparation of incense: 3% guaiacol, trans, trans-2,4-heptadienal 3%, 4-methylguaiacol 4%, ethyl valerate 7%, 3 - Acetyl-2,5-dimethylfuran 2%, furfural 2%, ethyl butyrate 2%, 2-ethylpyrazine 4%, eugenol 6%, 4-vinylphenol 2%, 2, 5-Dimethyl-3-acetylfuran 2%, 2,3-dimethylpyrazine 4%, methyl eugenol 2%, 5-methylfurfural 2%, maltol 2%, acetic acid 13%, Mix 5% ethanol and 35% distilled water and dissolve it fully.

[0040]3. Preparation of pickling solution: (per catty of water) 2g Angelica dahurica, 2g star anise, 2.5g cumin, 6g cinnamon, 3g ginger, 1.5g pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com