Collocation method of iron ores of steel raw material field

A configuration method and iron ore technology, applied in the metallurgical industry and the field of iron and steel raw material logistics information, can solve the problems of many constraints, tedious and time-consuming, and complicated operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

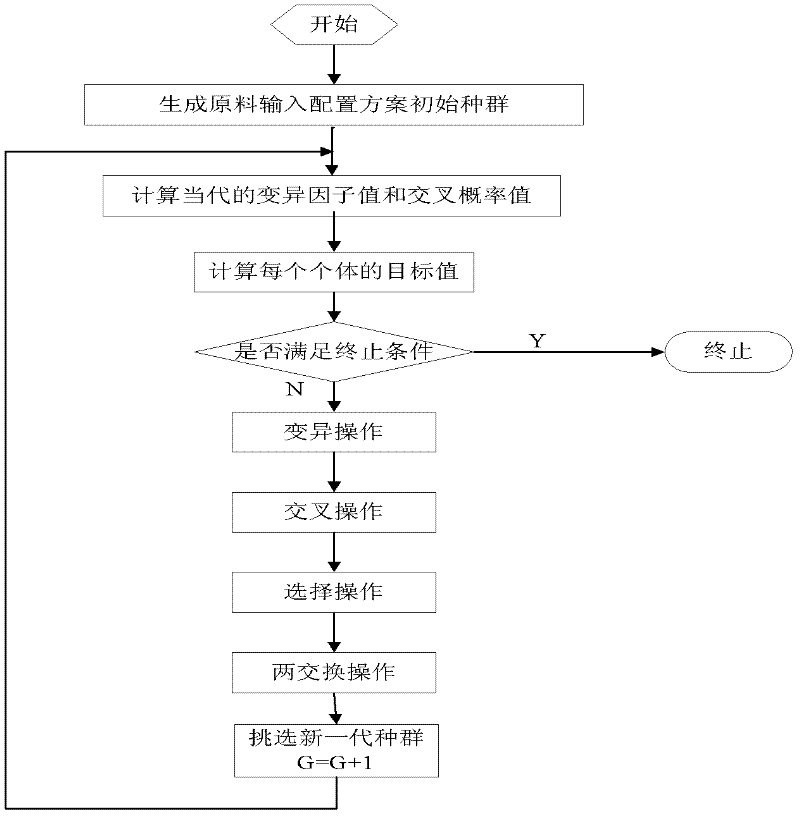

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0068] The iron ore input configuration method of the present embodiment adopts C++ language to realize, and is embedded in the visualized iron ore input configuration optimization system developed by Microsoft Visual Studio 6.0, this system is based on the information platform of the enterprise (the ERP system of the enterprise, Data warehouse system) and Microsoft SQL Server2000 data system.

[0069] This embodiment is realized on the integrated management system of the raw material field input optimization configuration method, and the system includes: a data download module, a data management module, a dynamic monitoring map module of the raw material field, an automatic configuration scheme generation module, a configuration scheme graphic display module and Result modification and upload module.

[0070] In this embodiment, 23 kinds of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com