Optical display panel, panel display module and shading structure forming method

A technology of optical display panel and shading structure, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of weakened effect, narrowed frame width design, light spillage, etc., and achieves the degree of suppressing light leakage, reducing the intensity, and simplifying the setting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

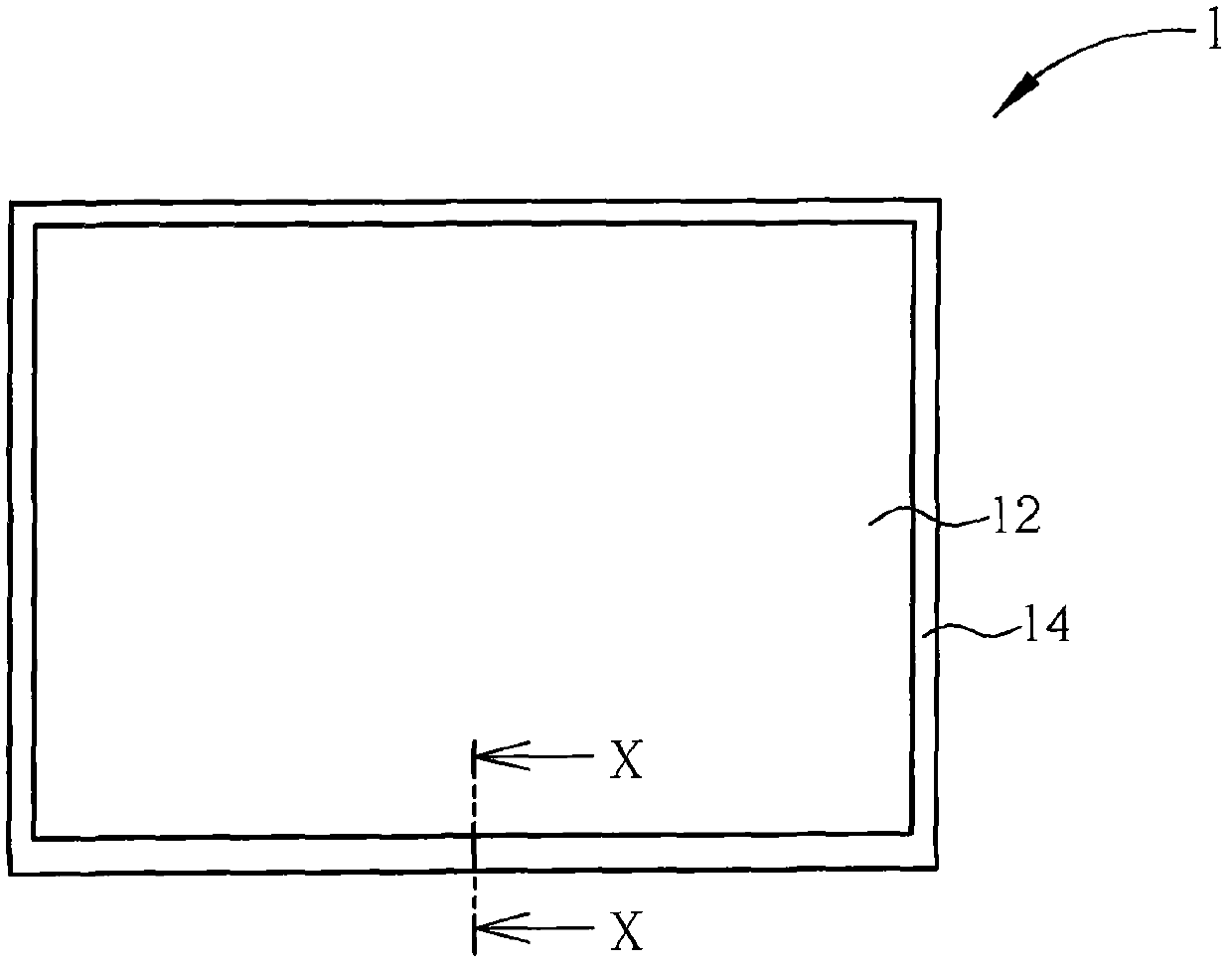

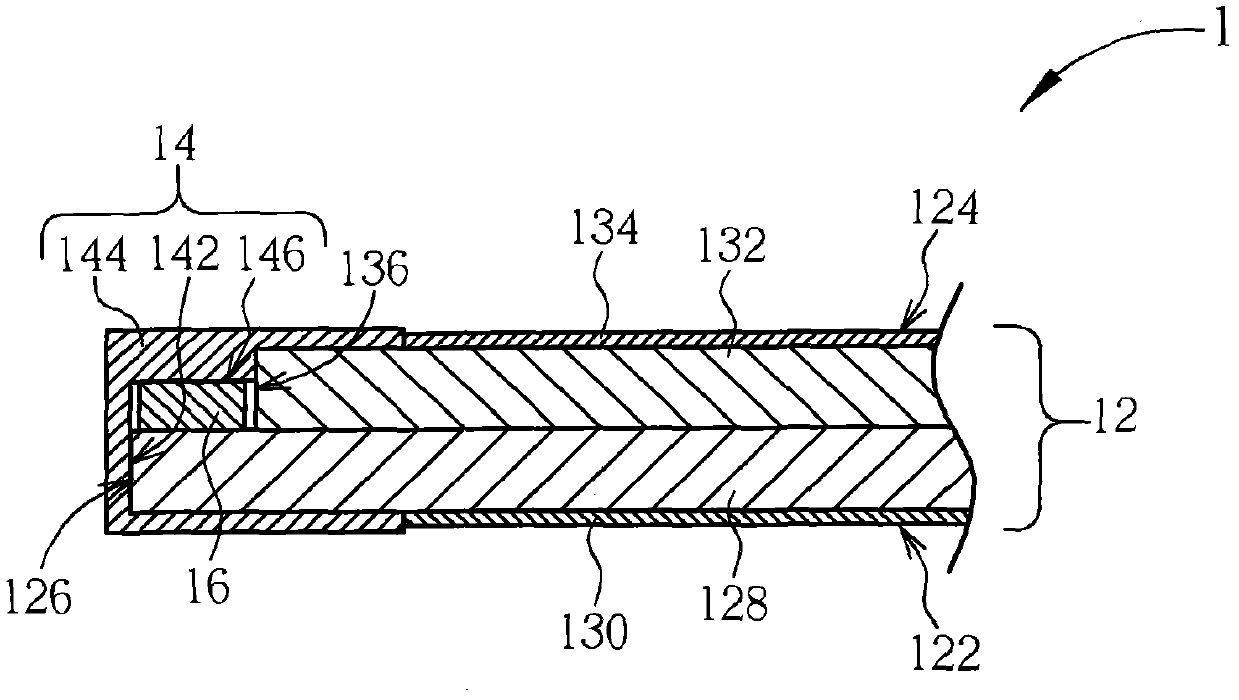

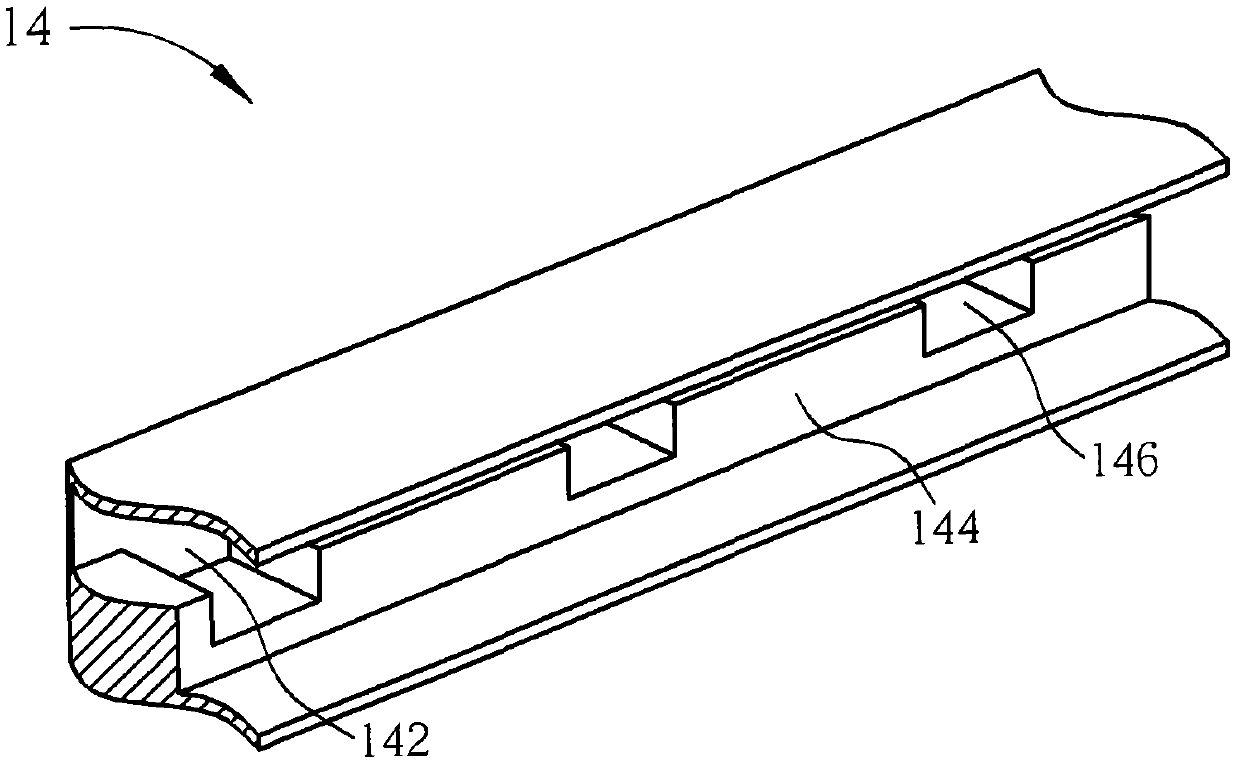

[0036] see figure 1 and figure 2 , figure 1 It is a top view of an optical display panel 1 according to a preferred embodiment of the present invention, figure 2 for the optical display panel 1 along figure 1 Partial sectional view of midline X-X. The optical display panel 1 comprises an optical multilayer structure 12, a plurality of shading elements 14 and a plurality of control chips 16 (in figure 2 only one of them is shown in ). The four sides of the optical multilayer structure 12 are covered with light shielding elements 14 , and the control chip 16 is disposed on one or more of the sides. The light leakage phenomenon of the optical display panel 1 can be effectively suppressed by utilizing the shielding and anti-reflection effect of the light-shielding member 14 .

[0037] Further, the optical multilayer structure 12 has a light incident side 122 , a light exit side 124 opposite to the light incident side 122 , and a side 126 adjacent to the light incident sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com