Nanomanipulator

A nano-manipulator and manipulator technology, applied in the field of nano-manipulators, can solve the problems of complex structure, small movement scale and large size of nano-manipulators, and achieve the effects of increasing the range of motion, small elongation range and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

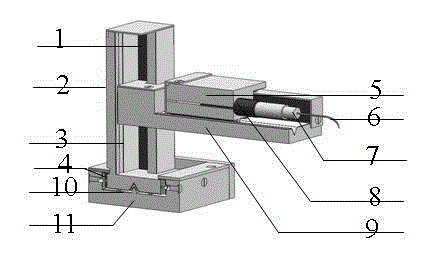

[0024] Such as figure 1 As shown, the nanomanipulator includes a positioning device and an actuator. The positioning device includes a moving track, a piezoelectric ceramic, and a moving table. The piezoelectric ceramic is installed in the moving track, and a pulse voltage is applied to the piezoelectric ceramic to drive the motion. The frictional contact of the table moves along the motion track; the actuator is connected with the motion table, and the actuator is the manipulator; the pulse period of the pulse voltage is equal to the telescopic period of the piezoelectric ceramic; the three positioning devices are vertically combined together , which are X-axis positioning device, Y-axis positioning device, and Z-axis positioning device respectively; there is a thin aluminum oxide sheet in the moving track; a small track is arranged in the moving trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com