Fiber-optic loop structure wound in vertically symmetrical cross manner for fiber-optic gyroscope and winding method

A technology of fiber optic gyroscope and fiber optic ring, which is applied in the direction of Sagnac effect gyroscope, etc., can solve the problems of stress generated by fiber optic coil, heat flux difference, uneven distribution of temperature field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the drawings and embodiments.

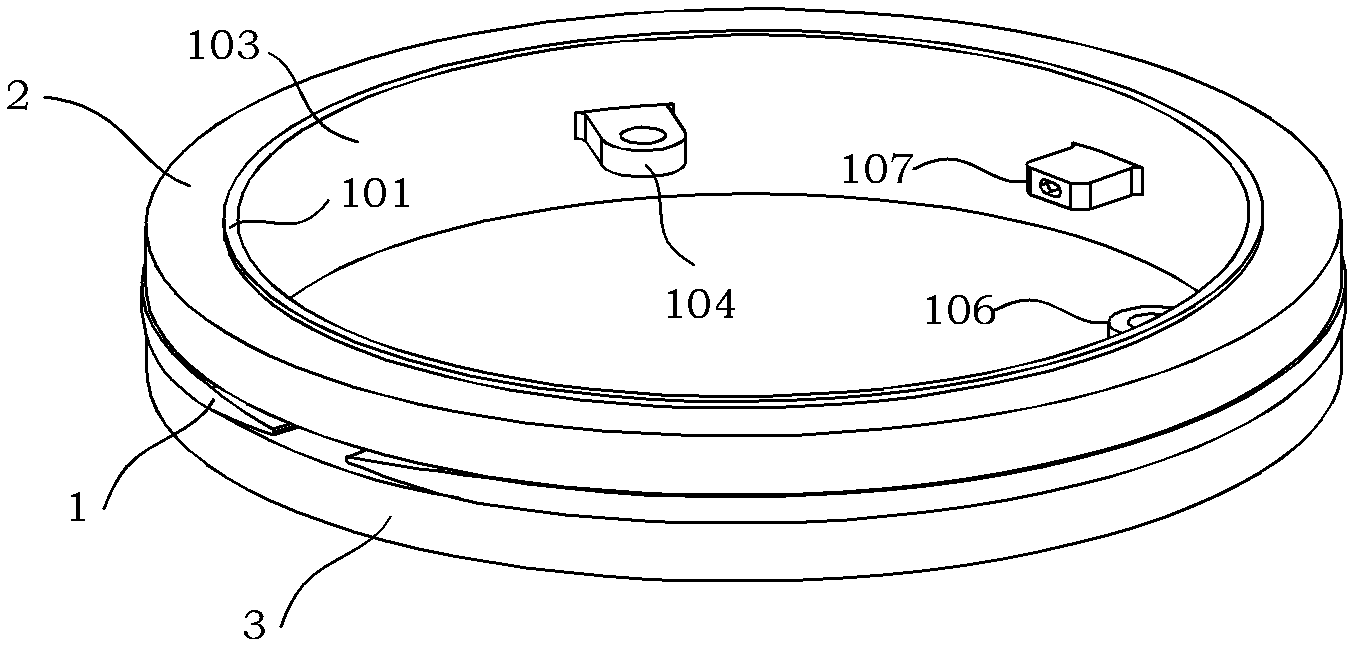

[0035] The present invention is an up and down symmetrical cross-wound fiber ring structure for fiber optic gyroscope, such as figure 1 , figure 2 As shown, the fiber ring frame 1 is included.

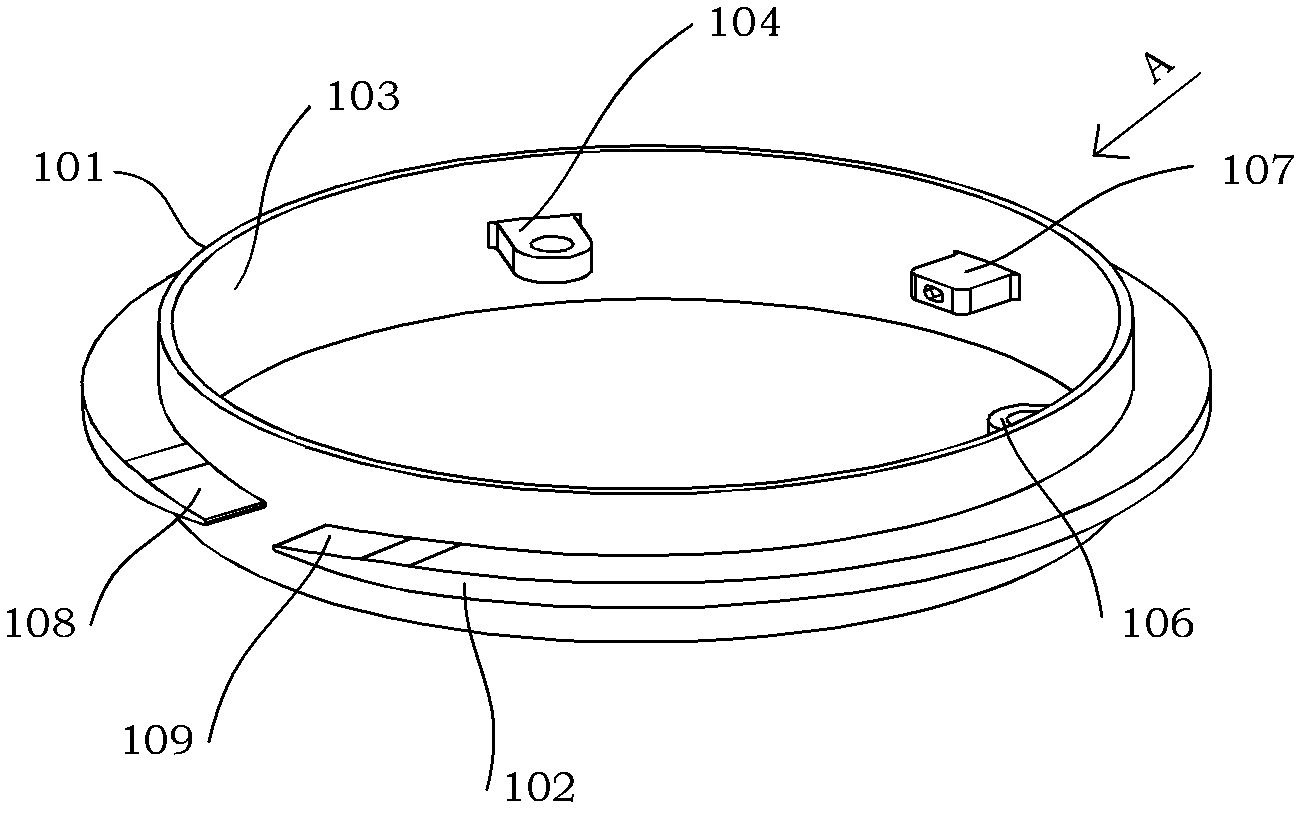

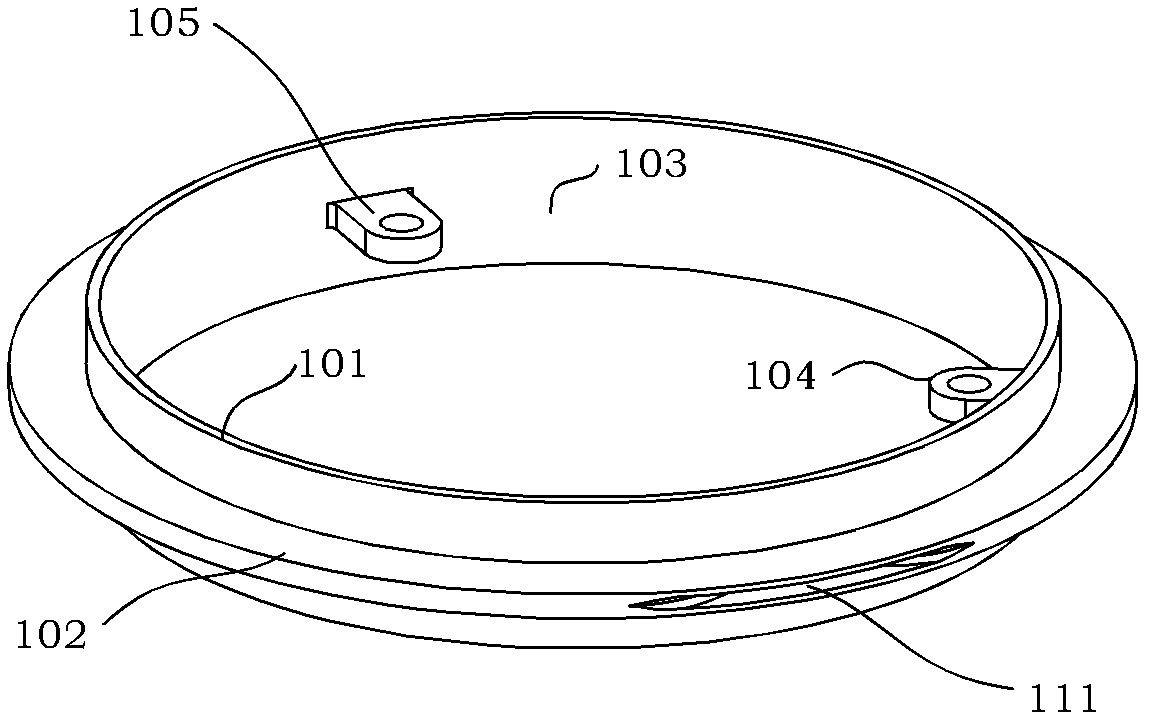

[0036] Fiber ring skeleton 1 such as figure 2 , Figure 2A , Figure 2B As shown, it includes a fiber-wound column 101, an intermediate flange 102, an A lug 104, a B lug 105, a C lug 106, and a D lug 107.

[0037] An intermediate flange 102 is provided on the periphery of the fiber winding column 101. A fiber passing slope 108 and a B fiber passing slope 109 are provided on the intermediate flange 102. A fiber passing gap 110 is formed between the A fiber passing slope 108 and the B fiber passing slope 109.

[0038] Three lugs are evenly distributed on the inner wall 103 of the fiber winding column 101, namely A lug 104, B lug 105 and C lug 106. The three lugs are distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com