Simple measurement setting-out method

A simple and simple technology for measuring and laying out. It is applied in the directions of measuring devices, measuring instruments, surveying and mapping, and navigation. It can solve the problem of difficulty in completing the work of measuring and laying out. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

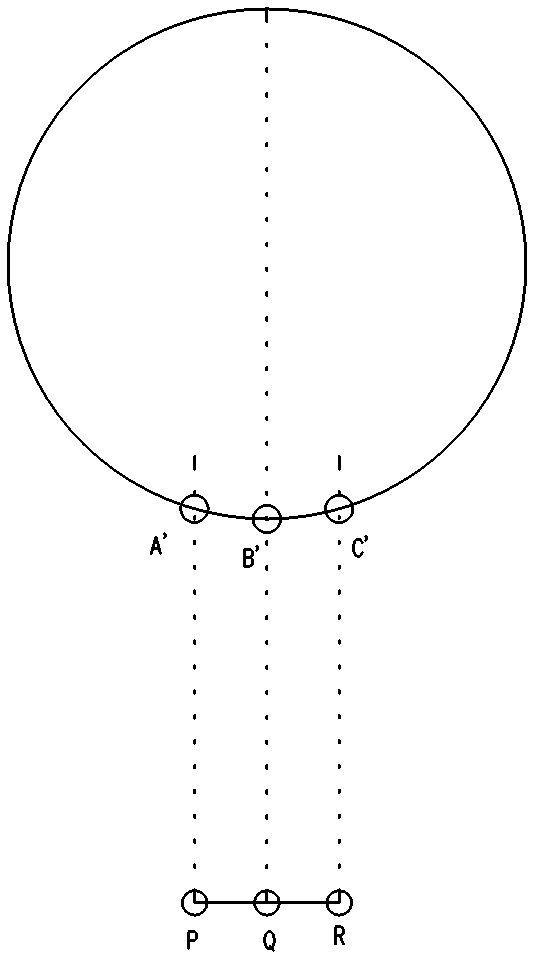

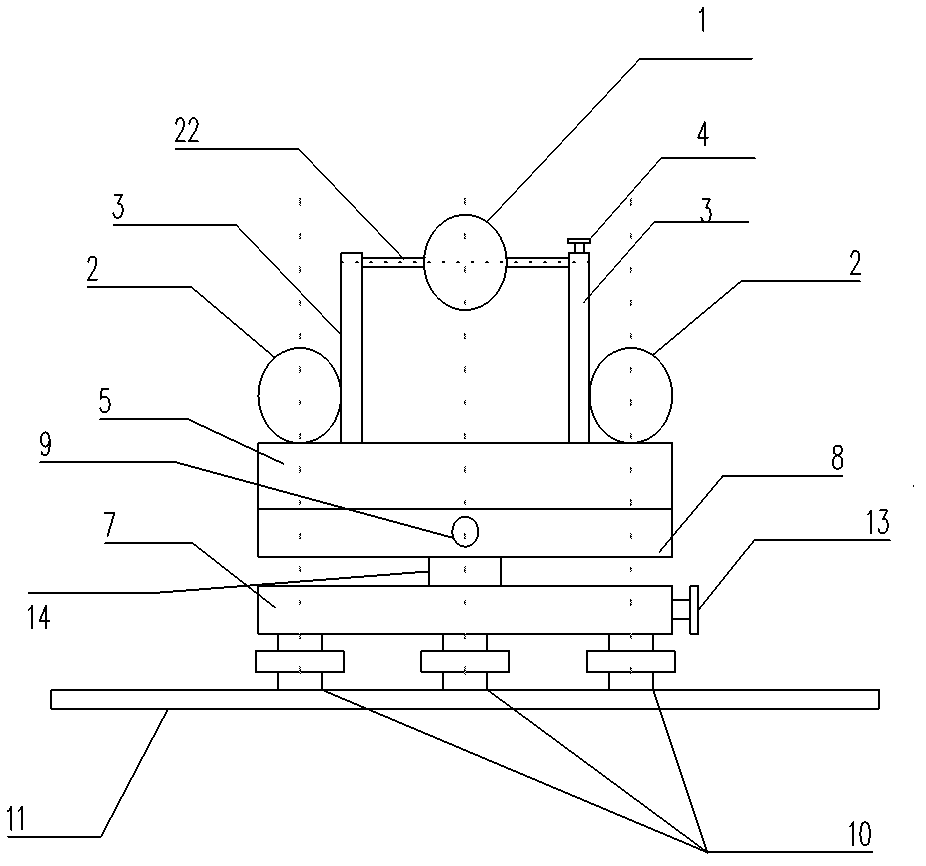

[0031](a) Connect the 0° points left during the manufacture and installation of each circle of vertical equipment, and connect the 0° points on each circle to lead to the 0° line on the facade; (b) Determine the 0° line by visual observation (c) Adjust the working light source of the lead guide so that the light emitted by the working light source is aligned with any first point on the 0° line of the facade, and at the same time, the light emitted by the calibration light source of the lead guide shines on the vertical equipment on the shell, so as to obtain the second point and the third point located on both sides of any first point; (d) measure the first arc length between the first point and the second point and the first point and the third point The second arc length between the points, if the first arc length and the second arc length are not equal, then keep the first point unchanged, move the thread guide until the first arc length and the second arc length The differ...

Embodiment 2

[0034] (a) Connect the 0° points left during the manufacture and installation of each circle of vertical equipment, and connect the 0° points on each circle to lead to the 0° line on the facade; (b) Determine the 0° line by visual observation (c) Adjust the working light source of the lead guide so that the light emitted by the working light source is aligned with any first point on the 0° line of the facade, and at the same time, the light emitted by the calibration light source of the lead guide shines on the vertical equipment on the shell, so as to obtain the second point and the third point located on both sides of any first point; (d) measure the first arc length between the first point and the second point and the first point and the third point The second arc length between the points, if the first arc length and the second arc length are not equal, then keep the first point unchanged, move the thread guide until the first arc length and the second arc length The diffe...

Embodiment 3

[0037] (a) Connect the 0° points left during the manufacture and installation of each circle of vertical equipment, and connect the 0° points on each circle to lead to the 0° line on the facade; (b) Determine the 0° line by visual observation (c) Adjust the working light source of the lead guide so that the light emitted by the working light source is aligned with any first point on the 0° line of the facade, and at the same time, the light emitted by the calibration light source of the lead guide shines on the vertical equipment on the shell, so as to obtain the second point and the third point located on both sides of any first point; (d) measure the first arc length between the first point and the second point and the first point and the third point The second arc length between the points, if the first arc length and the second arc length are not equal, then keep the first point unchanged, move the thread guide until the first arc length and the second arc length The diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com