Automotive shock absorber

A technology of automobile shock absorbers and guides, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., and can solve problems such as high oil pressure, shock absorber empty travel, and oil storage tank foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

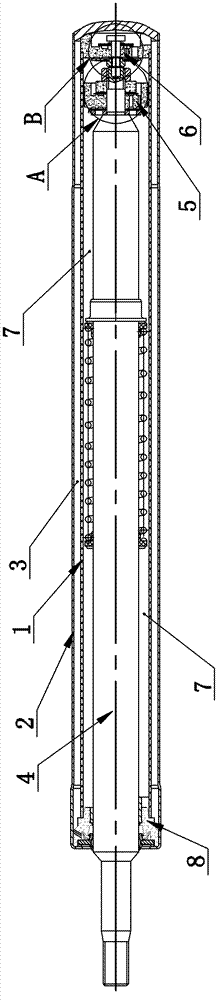

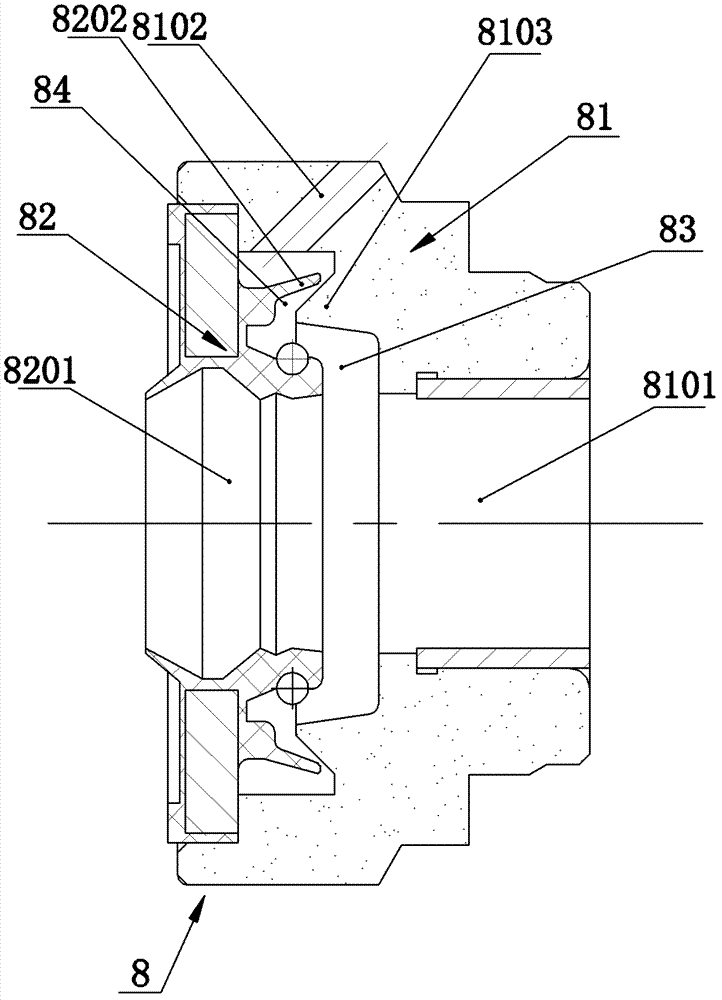

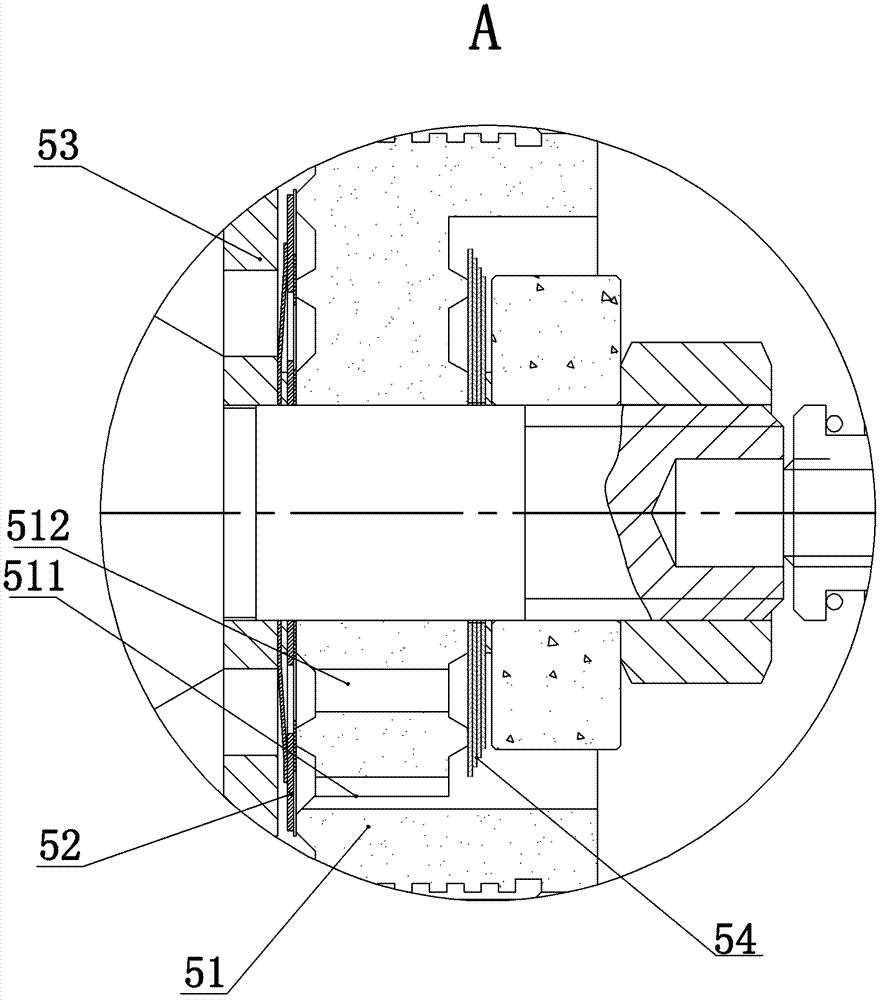

[0027] See attached figure 1 to attach Figure 8 , the automobile shock absorber disclosed by the present invention comprises an inner cylinder 1 and an outer cylinder 2, an oil storage cylinder 3 is formed between the inner cylinder 1 and the outer cylinder 2, and a connecting rod 4, a piston valve 5 and a bottom valve 6 are arranged in the inner cylinder 1 , the piston valve 5 is sleeved on the connecting rod 4, the bottom valve 6 is arranged at the bottom of the inner cylinder 1, the piston valve 5 divides the inner cylinder 1 into upper and lower working cylinders 7, and the connecting rod 4 corresponds to the inner cylinder 1 and the top of the outer cylinder 2 are provided with a guide sealing device 8. The guide seal device 8 includes a coaxially arranged guide 81 and an oil seal seat 82. Through holes 8101, 8201, one end of the oil seal seat 82 is embedded in one end of the guide 81, and an oil inlet passage 83 and an oil guide chamber 84 are arranged between the oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com