Crowned teeth slewing bearing

A technology of slewing bearings and drum-shaped teeth, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of slewing bearings, etc., and achieve the effects of reducing broken teeth, improving contact adjustment, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structural form of the drum tooth slewing bearing of the present invention is the same as the general slewing bearing structure, and is composed of an outer ring, an oil cup, an upper seal, a rolling body, a spacer block, an inner ring, an upper seal, a plug and a tapered pin.

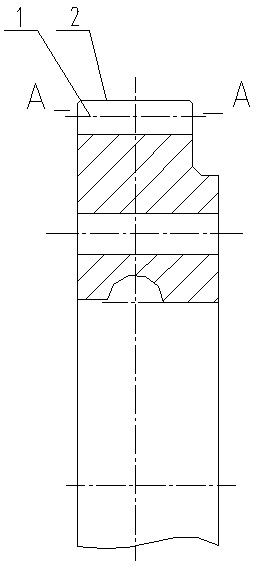

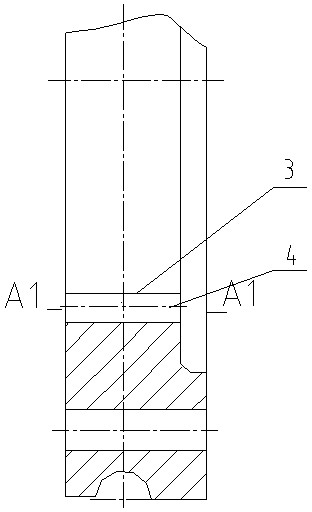

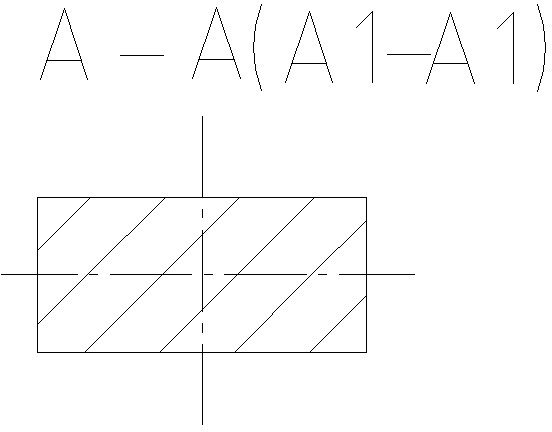

[0022] Such as figure 1 with Figure 4 As shown, the teeth are straight teeth and drum-shaped external tooth slewing bearings. The difference between the two is that the tooth profile of the external tooth slewing bearings with straight teeth is a straight line. (Such as image 3 shown), the profile of the 1-axis cross-section of the addendum circle is also a straight line; the tooth part is an external gear slewing bearing with drum-shaped teeth, and the indexing circle cut off on the 6-axis section of the addendum circle is an arc. It is called the displacement circle 5, the displacement circle is spherical, and the tooth profile of the cutting section of the indexing circle is drum-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com