Full water lubrication pass shaft type water hydraulic piston motor

A plunger motor, water lubrication technology, applied in the field of fluid machinery, can solve the problems of unreported actual effect, difficult processing, complex structure, etc., to avoid high stress corrosion, improve mechanical efficiency, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

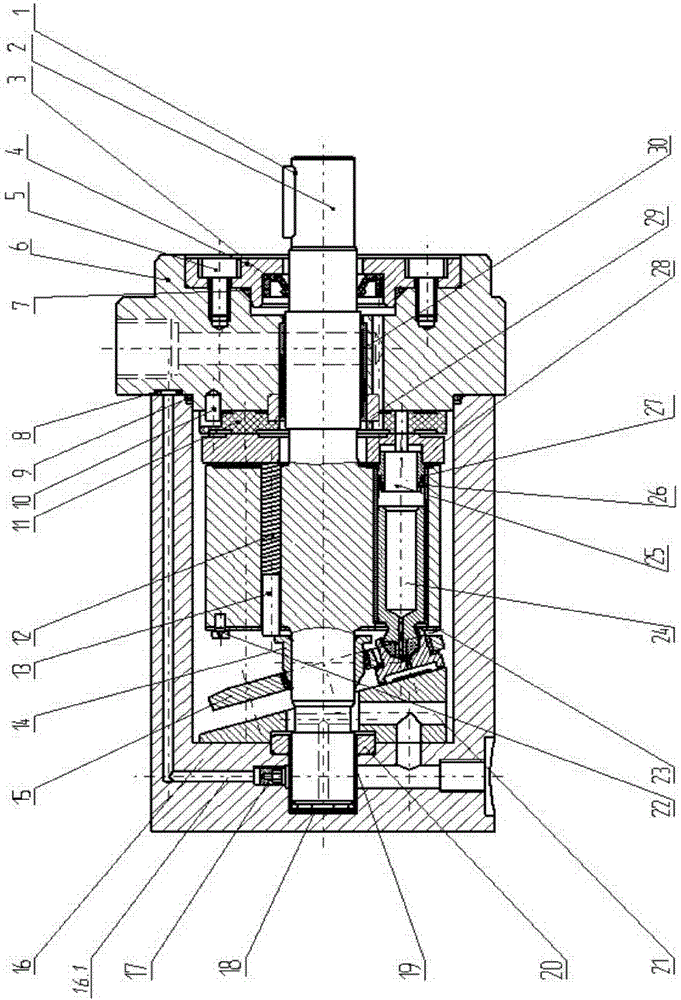

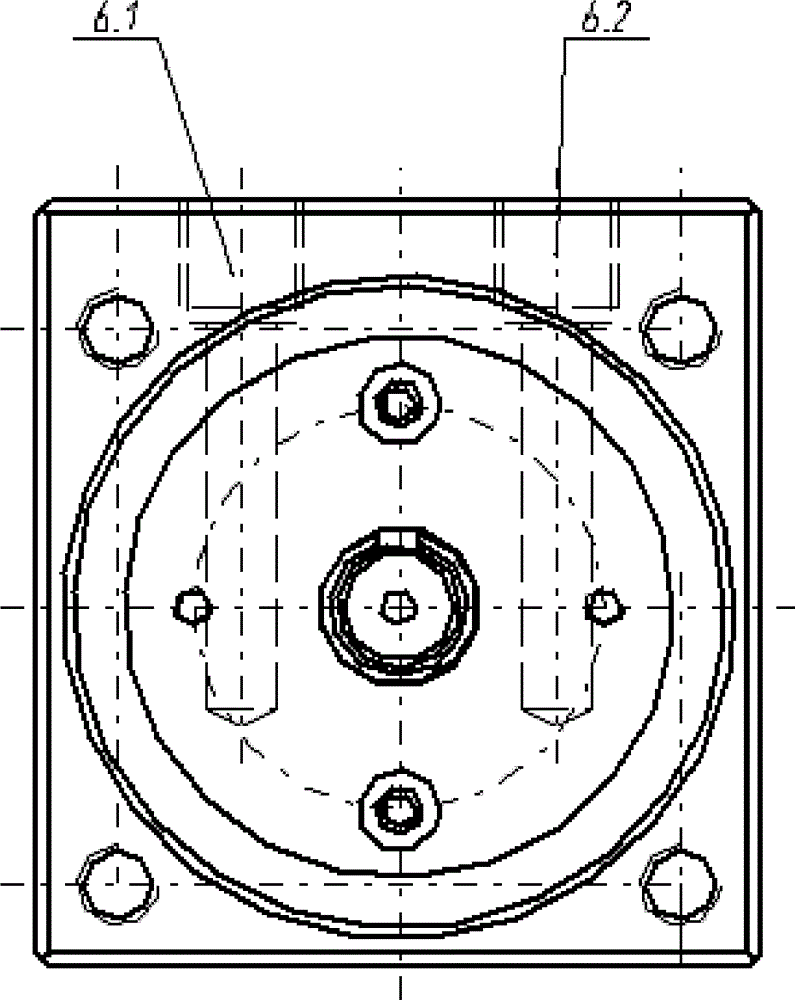

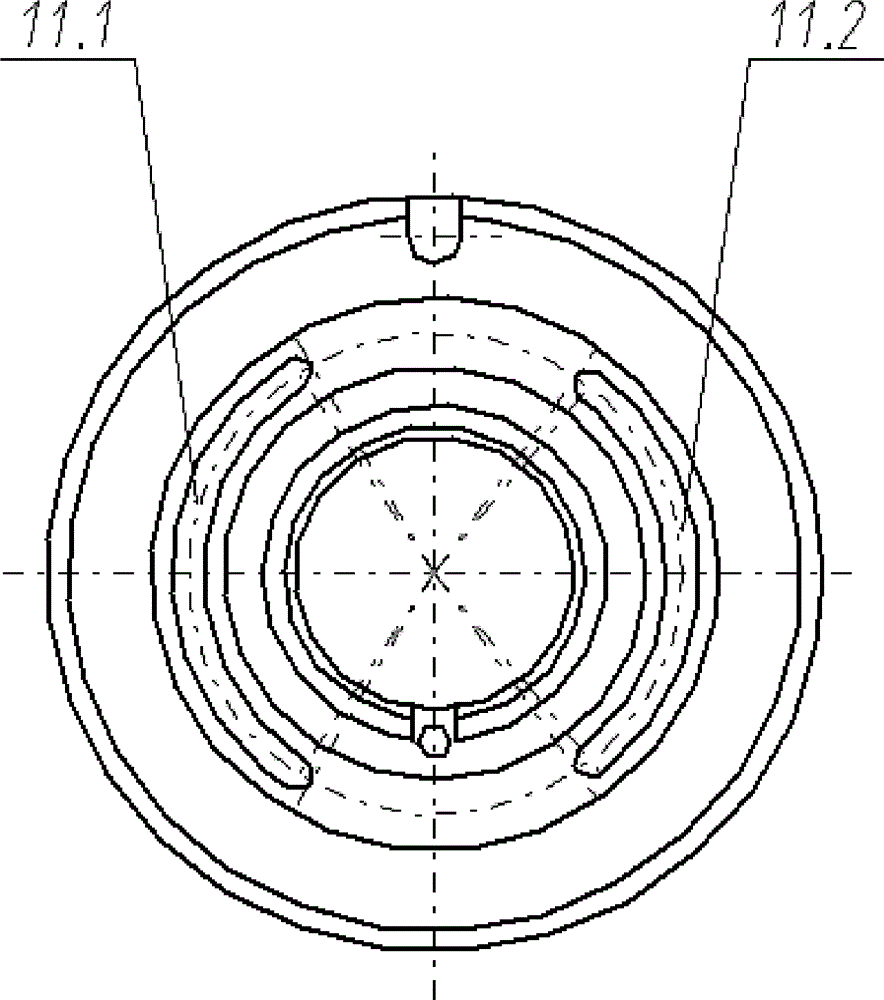

[0030] implement Figure 1~4 Combined with a fully water-lubricated through-axis water hydraulic plunger motor, it is mainly composed of a casing (mainly composed of a large end cover 6, a small end cover 4, and a housing 16), and is installed in the housing 16 to be rotatable. The cylinder shaft 2, the swash plate 21 fixed in the housing 16, the plunger shoe assembly 24 and the flow distribution device (including the flow distribution plate 11, the floating plate 28, and the floating sleeve 25) are composed.

[0031] The large end cap 6 is fixedly connected with the housing 16 through threads, the small end cap 4 and the large end cap 6 are fixedly connected through the screws 5, and the large end cap 6, the housing 16 and the small end cap 4 form a shell.

[0032] The through-shaft structure is adopted, and the inner hole of the housing 16 is equipped with a plastic gasket 18. The cylinder shaft 2 is inserted into the inner hole of the housing 16 and directly contacts with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com