Control device of variable valve exhaust tube

A technology of control device and exhaust pipe, applied in the direction of exhaust device, muffler device, engine control, etc., can solve the problems of limiting the maximum horsepower of the engine, carbon deposition of the engine, and high cost, and achieve the effect of increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

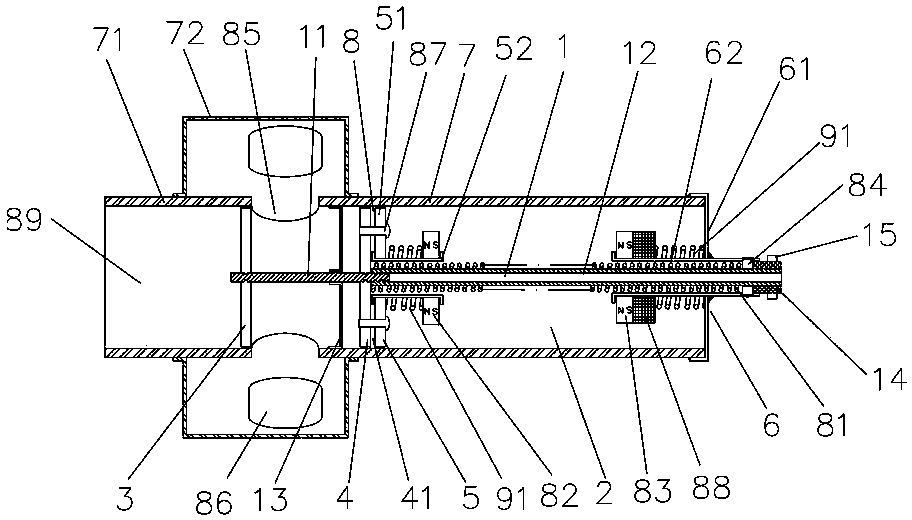

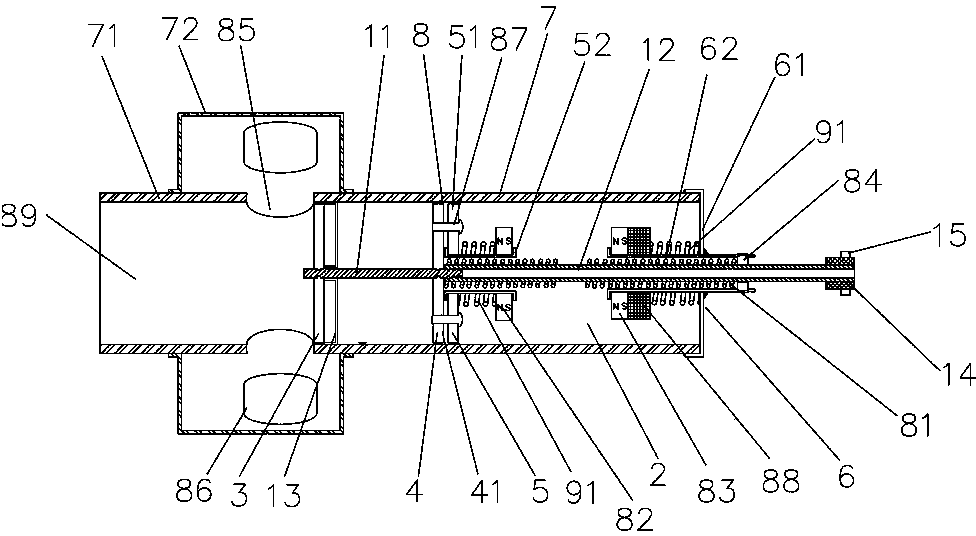

[0016] Reference Figure 1~2 , A control device for a variable valve exhaust pipe, comprising a main shaft 1 and a pipe body 7. The main shaft 1 is composed of a solid shaft 11 and a hollow shaft 12. Both the head and the tail end of the main shaft 11 are provided with grooves, and the hollow The shaft 12 is fixed on the pit of the solid shaft 11 by hydraulic pressure, so that the main shaft 1 forms a structure with a small front and a large rear, thereby reducing heat conduction, and the use of the hollow shaft 12 can further reduce heat conduction and reduce the stress of the control device main shaft 1. The weight reduces the inertia of motion, thereby increasing the service life of the spring 81 and improving the overall sensitivity of the control device. The solid shaft 11 is pressure-fixed with a piston plate 3 at the head end, and the solid shaft 11 and the hollow shaft 12 are fixedly provided with a supporting plate set 8 , The supporting piece group 8 includes a main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com