Oil pumping unit with fixed ring rack

A ring-shaped rack and pumping unit technology, applied in mechanical equipment, belts/chains/gears, and production fluids, etc., can solve the problem of not having long-stroke and large-load pumping units, and achieve a simplified and reasonable structure design. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

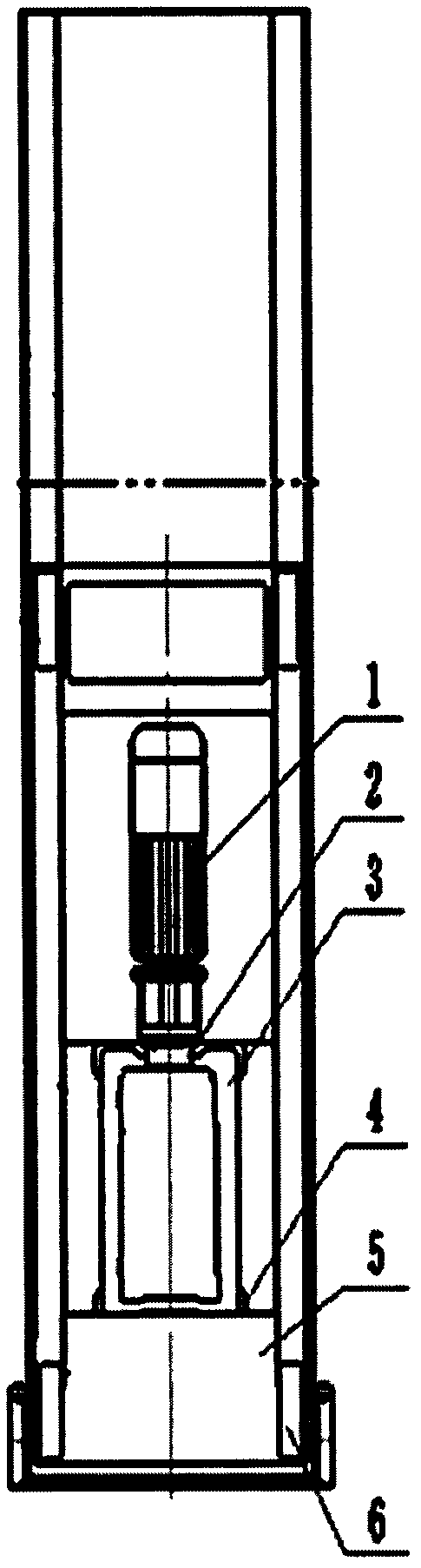

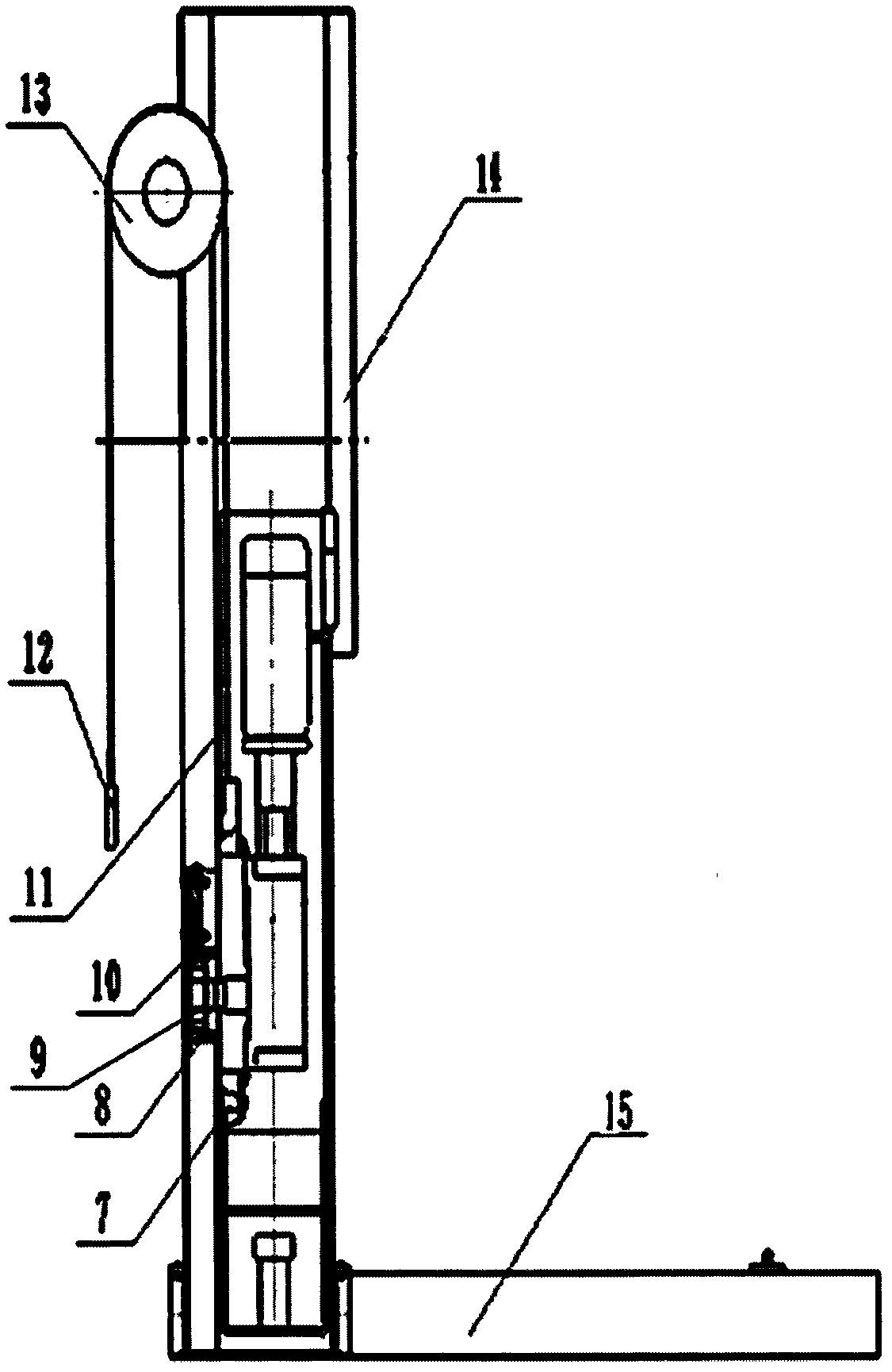

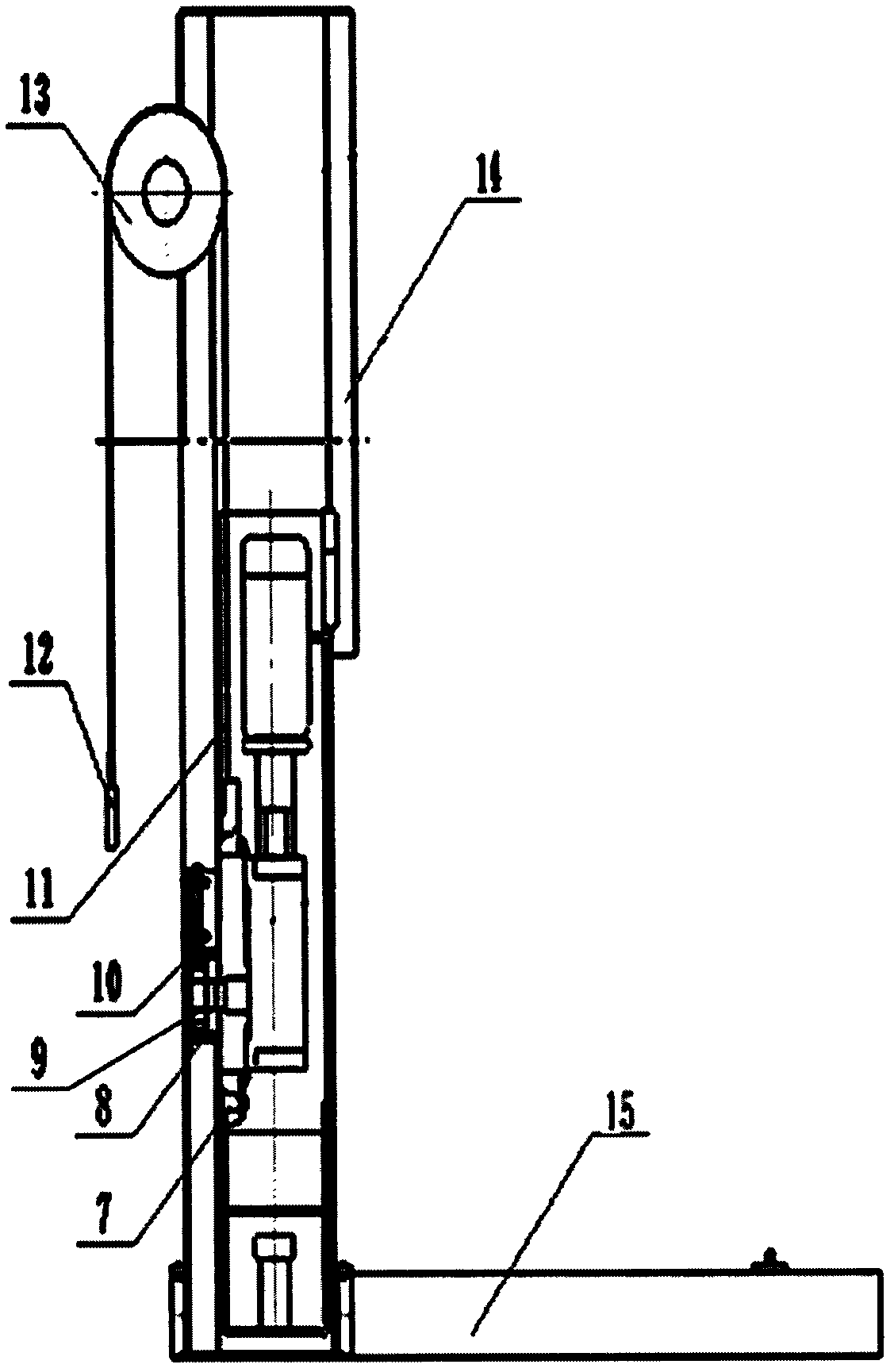

[0011] Such as figure 1 and figure 2 As shown, the fixed ring rack pumping unit includes a base 15, a frame 14 is installed on the base 15, an operating mechanism fixed on the frame 14, a balance reciprocating mechanism connected with a suspension system at one end, and the balance reciprocating The mechanism is equipped with a drive reversing mechanism, wherein: the suspension system includes a drum 13 and a suspension belt 11, and one end of the suspension belt 11 is connected with a rope suspension 12; the operating mechanism is fixed on the frame 14 The ring rack 10; the balance reciprocating mechanism includes a balance box 5 with one end connected to the suspension belt 11; 1. The pinion 9 and the guide wheel 8 installed on the output shaft of the reducer 2, the pinion 9 meshes with the ring rack 10, and the reversing track 7 installed transversely on the balance box 5 is connected with the reducer 2 and passed through A plurality of rollers 4 limit the reversing disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com