Large-capacity super-spun-yarn cursory spindle of high speed machine

A high-capacity, high-speed machine technology, applied in woven fabrics, textiles and papermaking, etc., can solve the problems of high spindle friction, easy breakage of fine yarns, uneven weaving, etc. The effect of weaving quality and throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

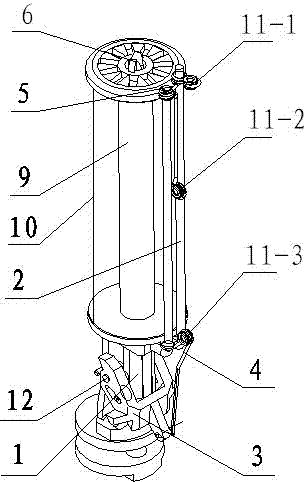

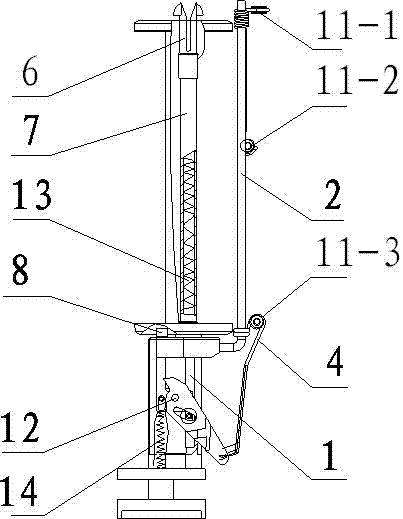

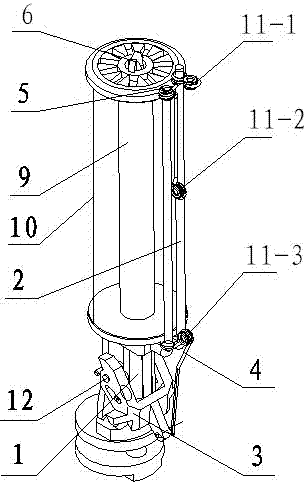

[0010] Embodiment 1: The horse-riding spindle includes: spindle seat 1, guide post 2, thread pendant 3, connecting rod 4, fixed frame 5, cap 6, bobbin shaft 7, brake pin 8, bobbin 9, threader 11, Pin 12, long stage clip 13 and: short stage clip 14; Brake pin 8 is arranged in spindle base 1, and the bottom of brake pin 8 has short stage clip 14, and line pendant 3 is connected on the spindle base 1 by pin 12, and line pendant One end of 3 is connected with connecting rod 4; one side of spindle base 1 is connected with guide post 2, and connecting rod 4 is sleeved on the guide post; the upper end of spindle base 1 is connected with bobbin shaft 7, and the bobbin shaft The upper end of 7 has clamping cap 6, and long clip spring 13 is arranged in bobbin shaft 7, and bobbin 9 is sleeved on bobbin shaft 7; An upper threader 11-1 is connected, a guide post threader 11-2 is connected at the middle of the guide post, and a lower threader 11-3 is connected at the bottom of the guide pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com