Cross-linked biologically degradable carrier polymer, micelle and vesicle, and preparation method and application of the cross-linked biologically degradable carrier polymer, micelle and vesicle

A technology of carrier polymers and polymers, applied in the field of biomedical materials, can solve the problems of poor stability of polymer micelles and vesicles, and achieve the effects of increasing difficulty, facilitating medical applications, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the cross-linked biodegradable carrier polymer, the specific steps are as follows:

[0038] (1) Firstly, the ring-opening polymerization of allyl glycidyl ether is initiated by the PEG protected by the end methoxy group, and the two-block polymer polyethylene glycol-polyallyl glycidyl ether is obtained;

[0039] (2) Use the two-block polymer obtained in step (1) to initiate ring-opening polymerization of ester monomers to prepare a three-block polymer polyethylene glycol-poly(side allyl substituted ethylene glycol)-polyester; The polyester is a polymer of L-lactide, D-lactide, racemic lactide, glycolide or ε-caprolactone, or a random copolymer of one or two of the above monomers thing;

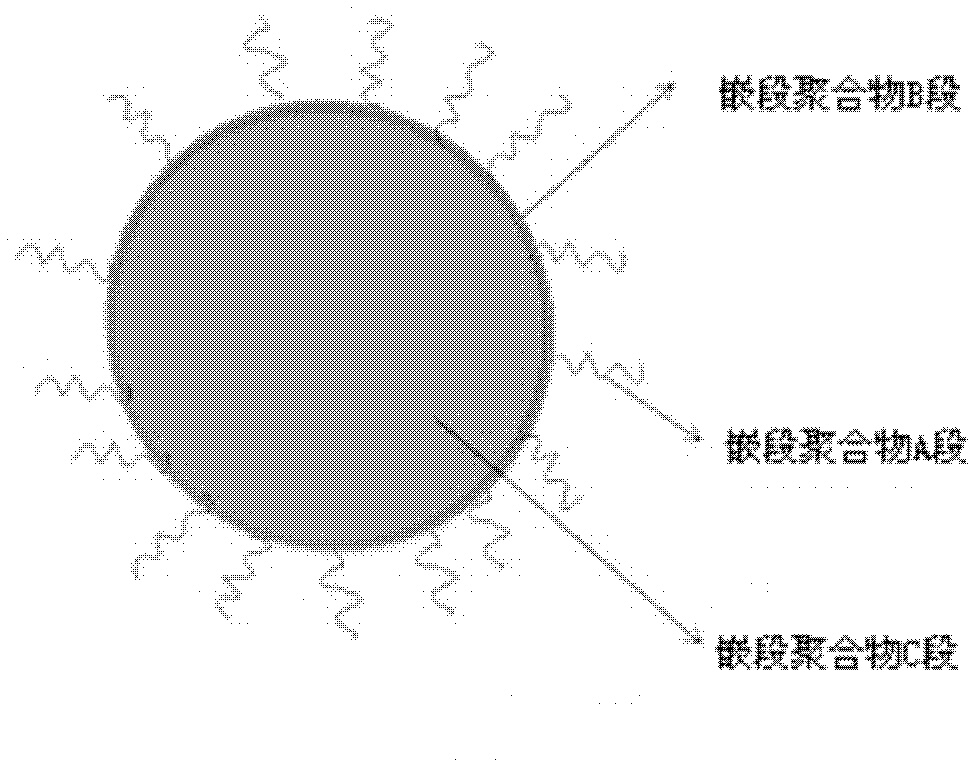

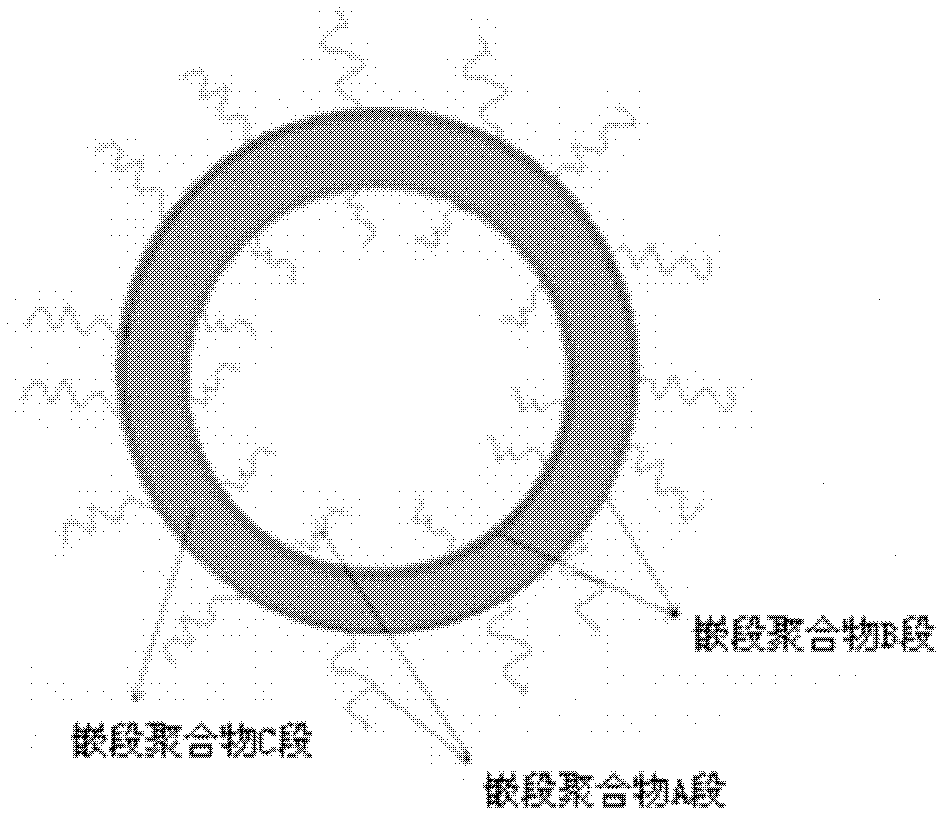

[0040] (3) Addition reaction of the mercapto-containing monomer with the allyl group on the triblock polymer obtained in step (2) converts the double bond of the polymer side chain into a different functional group to obtain the A-B-C type triblock polymer. ...

Embodiment 1

[0079] Embodiment 1: the polymer PEG of preparation triblock 5000 -PEG / COOH -PCL 38000 :

[0080] Step 1: Under nitrogen protection, take PEG 5000 (PEG with a molecular weight of 5000) 2.0g (0.4mmol), add toluene to carry out azeotropic water removal, after 2 hours, add cerium hydroxide 74mg (0.44mmol) in the reaction vessel, stir and react at 60°C for 2 hours, then remove the solvent , add 0.95mL allyl glycidyl ether (AGE, 8.0mmol), react at 40°C for 24 hours, cool to room temperature, settle with 400mL ether, filter, and obtain 2g of solid powder after vacuum drying, the yield is 69%, the obtained product It is PEG-PAGE, and the molecular weight of the PAGE block measured by nuclear magnetic resonance method is 1700;

[0081] The second step: Take 0.2g (0.03mmol) of the above PEG-PAGE and dissolve it in 20mL of THF. After stirring and dissolving, add 0.01mL of catalyst Zn[N(SiMe 3 ) 2 ] 2 and 1.2mL (0.01mmol) of ε-caprolactone, after stirring at room temperature for ...

Embodiment 2

[0083] Example 2: Preparation of triblock polymers of different molecular weights and different polyester monomers

[0084] Using the method of Example 1, by changing the amount of allyl glycidyl ether and polyester monomer, different polyester monomers and compounds containing different mercapto monomers, PEG- PEG / COOH -PCL block polymer, the specific results are shown in Table 1. The subscript after the polymer code in the table indicates the molecular weight of the block.

[0085] Table 1

[0086]

[0087] Note: In the table, CL stands for ε-caprolactone, LA stands for lactide, and GA stands for glycolide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com