Preparation method of water-soluble high molecular weight growth agent

A high-molecular-weight, extender technology, applied in the fields of sulfonate preparation, organic chemistry, etc., can solve the problems of no disclosure of product production and preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

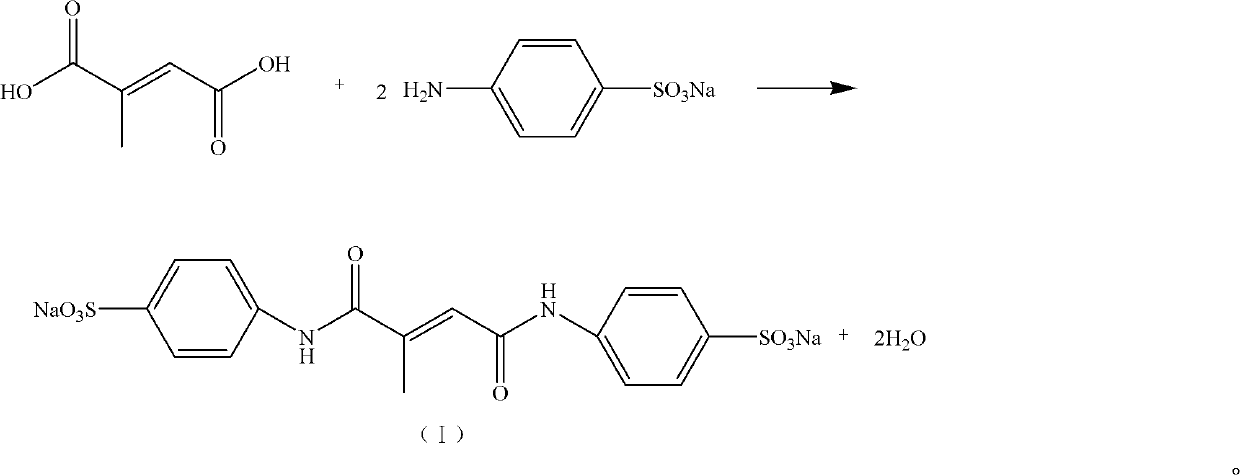

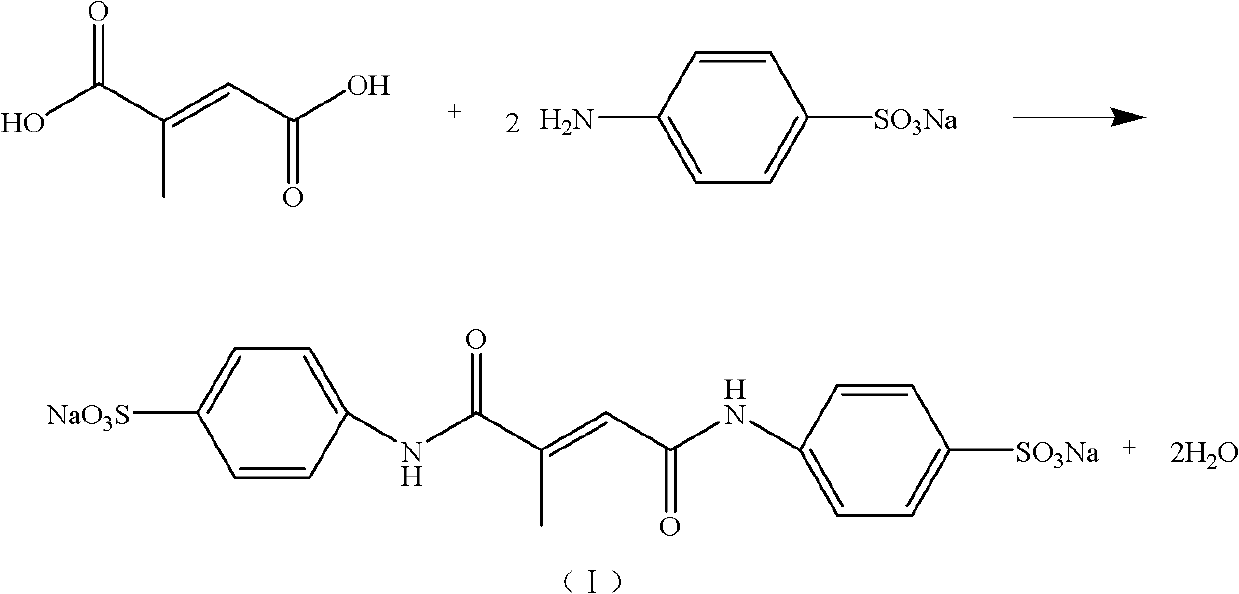

Method used

Image

Examples

Embodiment 1

[0020] 0.5 mole of methylbutenedioic acid (purity is 99.5%) joins in 500 grams of toluene together with 1.1 mole of 4-aminobenzenesulfonate sodium (purity 99%), and adds 3.2 grams of benzenesulfonic acid-based molecular sieve catalysts, Control the temperature of the reactor at 135°C to 140°C, keep reflux, and centrifuge the reaction solution (rotating speed 600r / min, time 5min) to remove the benzenesulfonic acid-based molecular sieve catalyst after observing that no more water is precipitated in the condensed toluene. Remove the toluene in the reaction solution of the benzenesulfonic acid-based molecular sieve catalyst by means of vacuum distillation (pressure-0.04MPa, temperature 110°C-115°C) with unreacted sodium 4-aminobenzenesulfonate and product 4,4' -Methyl butenediamide bis(sodium benzenesulfonate) separation, finally by recrystallization mode 4-aminobenzene sulfonate and product 4,4'-methyl butenediamide bis(benzenesulfonic acid Sodium 4-aminobenzenesulfonate in sodiu...

Embodiment 2

[0033] 0.5 mole of methylbutenedioic acid (purity 99.5%) joins in 500 grams of toluene together with 1.0 mole of 4-aminobenzenesulfonate sodium (purity 99%), and adds 3.2 grams of benzenesulfonic acid group molecular sieve catalysts, will The temperature of the reactor is controlled at 135°C to 140°C, and the reflux is maintained. When it is observed that no more water is precipitated in the condensed toluene, the reaction solution is centrifuged (rotating speed 600r / min, time 5min) to remove the benzenesulfonic acid-based molecular sieve catalyst. The toluene in the reaction solution of the benzenesulfonic acid-based molecular sieve catalyst is distilled under reduced pressure (pressure-0.04MPa, temperature 110°C-115°C) with unreacted sodium 4-aminobenzenesulfonate and product 4,4'-methyl 4-aminobenzenesulfonate and product 4,4'-methylbutenediamide bis(sodium benzenesulfonate) are finally separated by recrystallization The sodium 4-aminobenzenesulfonate in the mixture is remo...

Embodiment 3

[0035] 0.5 mole of methylbutenedioic acid (purity 99.5%) joins in 500 grams of toluene together with 1.3 mole of 4-aminobenzenesulfonate sodium (purity 99%), and adds 3.2 grams of benzenesulfonic acid group molecular sieve catalysts, will The temperature of the reactor is controlled at 135°C to 140°C, and the reflux is maintained. When it is observed that no more water is precipitated in the condensed toluene, the reaction solution is centrifuged (rotating speed 600r / min, time 5min) to remove the benzenesulfonic acid-based molecular sieve catalyst. The toluene in the reaction solution of the benzenesulfonic acid-based molecular sieve catalyst is distilled under reduced pressure (pressure-0.04MPa, temperature 110°C-115°C) with unreacted sodium 4-aminobenzenesulfonate and product 4,4'-methyl 4-aminobenzenesulfonate and product 4,4'-methylbutenediamide bis(sodium benzenesulfonate) are finally separated by recrystallization The sodium 4-aminobenzenesulfonate in the mixture is remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com