Spindle device for processing micro-hole electric spark based on magnetic levitation servo drive

A technology of servo drive and spindle device, applied in the direction of magnetic attraction or thrust holding device, electric processing equipment, accessory device, etc., can solve the problems of poor real-time tracking, low spindle servo response frequency, and low effective discharge rate, etc., to achieve Improve servo tracking speed, reduce processing auxiliary time, and achieve high-precision processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

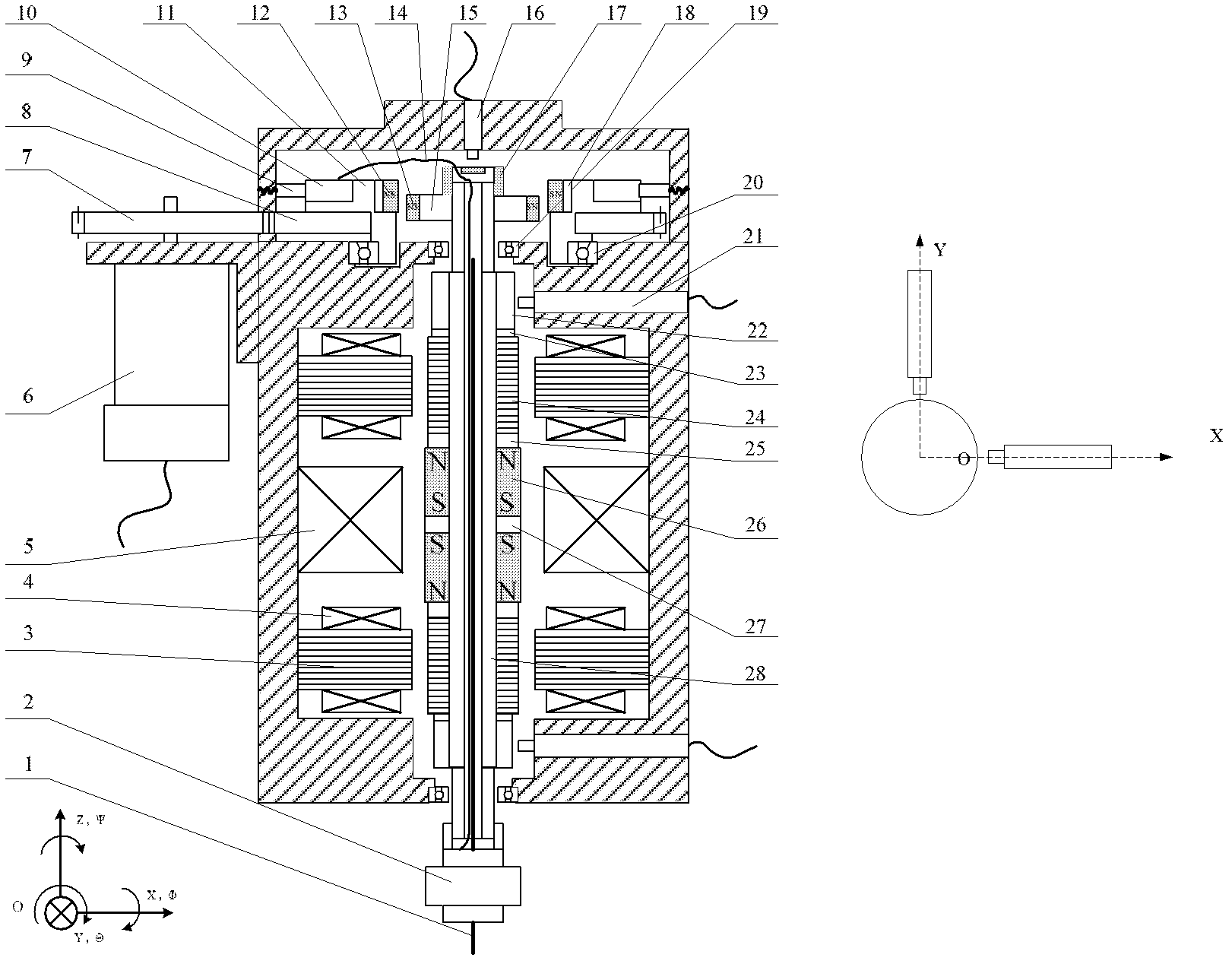

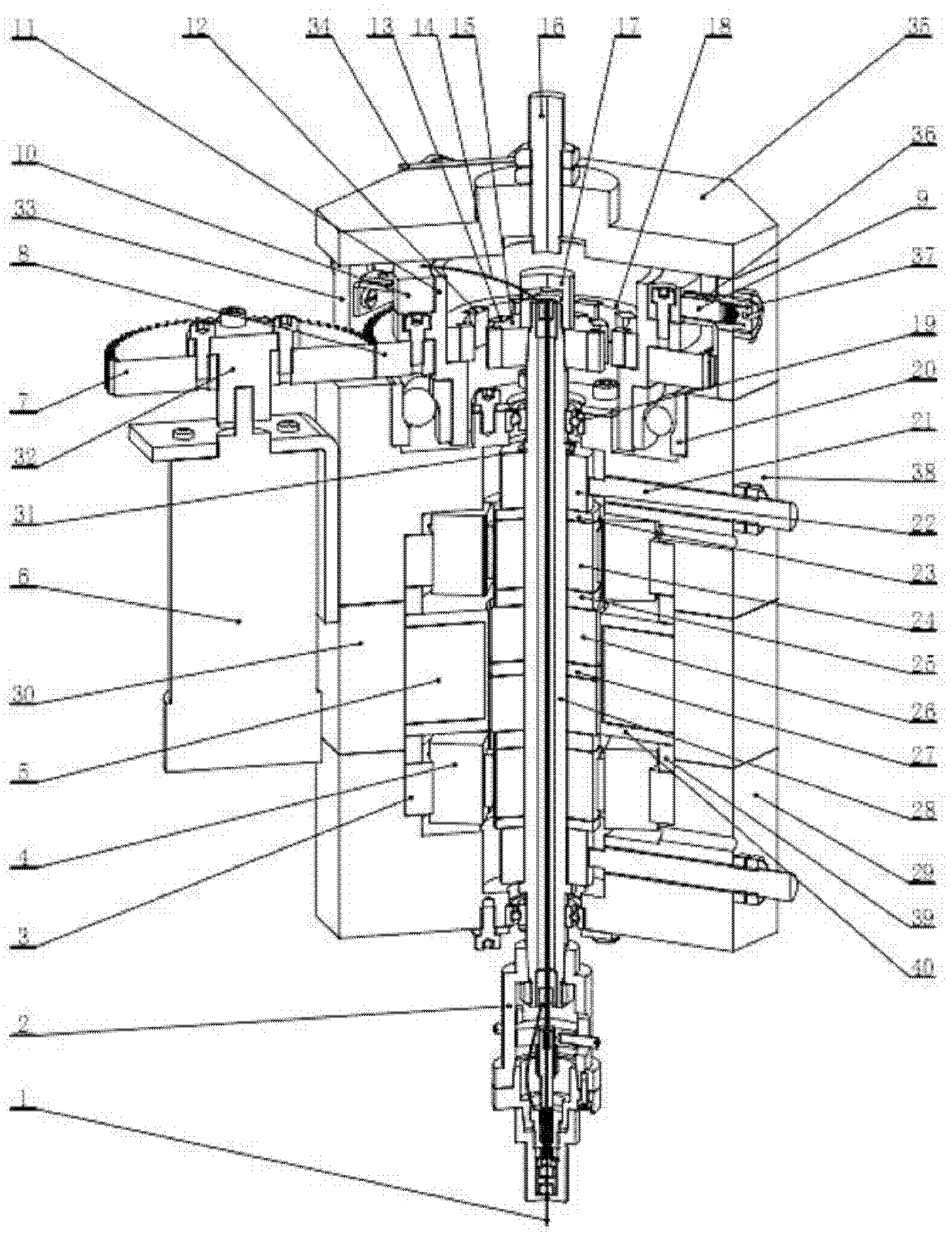

[0021] Such as Figure 1~Figure 5As shown, a spindle device for micro-hole EDM based on magnetic levitation servo drive in this embodiment includes a radial magnetic bearing stator core 3, a radial magnetic bearing stator coil 4, an axial magnetic bearing coil 5, DC motor with encoder 6, driving gear 7, driven gear 8, brush 9, slip ring 10, insulating turntable 11, outer rotor permanent magnet 12, inner rotor permanent magnet 13, flexible wire 14, magnetic coupling inner rotor 15. Axial eddy current displacement sensor 16, rotor cover 17, magnetic coupling outer rotor 18, holding bearing 19, angular contact ball be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com