Spiral insect catching machine

An insect trap, spiral technology, applied to the device, application, animal husbandry, etc. of catching or killing insects, can solve the problems of indoor use interference, physical hazards, and inappropriateness, etc., to facilitate injection molding production and low cost , to avoid the effect of unstable insecticide function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

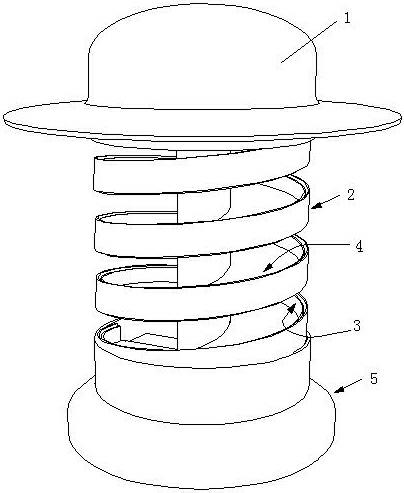

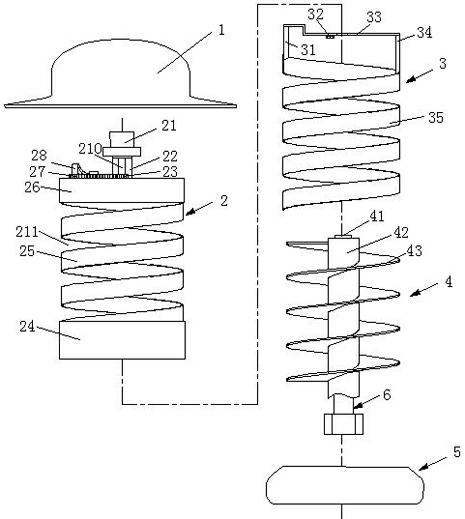

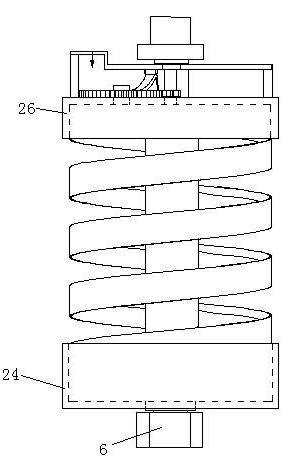

[0018] like Figure 1 to Figure 4 As shown, the present invention includes:

[0019] The screw cylinder 2 is composed of an upper fixing cover 26, a lower fixing cover 24, a fixing coil 25, and a lifting transmission assembly; the fixing coil is in the shape of a cylindrical spiral, and each coil of the spiral is provided with an up-down width and a pitch between the threads. There is a spiral opening 211, the upper end of the fixing coil is fixedly connected to the upper fixing cover, and the lower end is fixedly connected to the lower fixing cover; the upper fixing cover is provided with a lifting transmission assembly, and the lifting transmission assembly includes a motor 21, The pinion 23, the large gear 27, the inclined surface block 28, the motor is fixed on the bracket 22, the motor shaft 210 is arranged vertically downward, the middle of the shaft is provided with a pinion, the pinion meshes with the large gear, and the upper edge of the large gear is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com