Crammer for ducks and geese

A technology of driving motor and rotating arm, applied in poultry industry, application, animal husbandry, etc., can solve the problems of insufficient material suction, affecting the speed of feeding, affecting the suction and extrusion accuracy of the material cylinder, etc. The effect of fast and uniform suction, extended service life and high precision of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

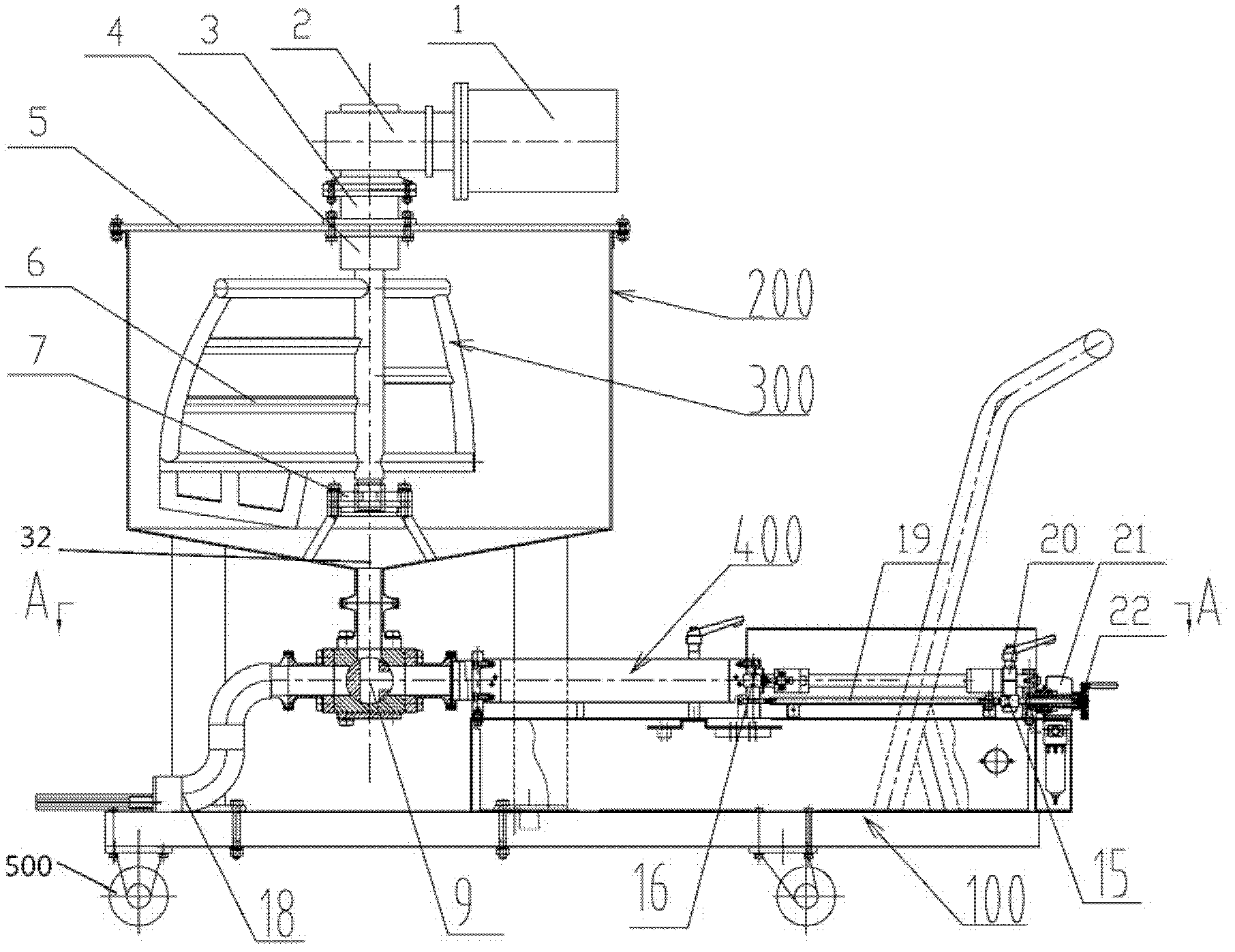

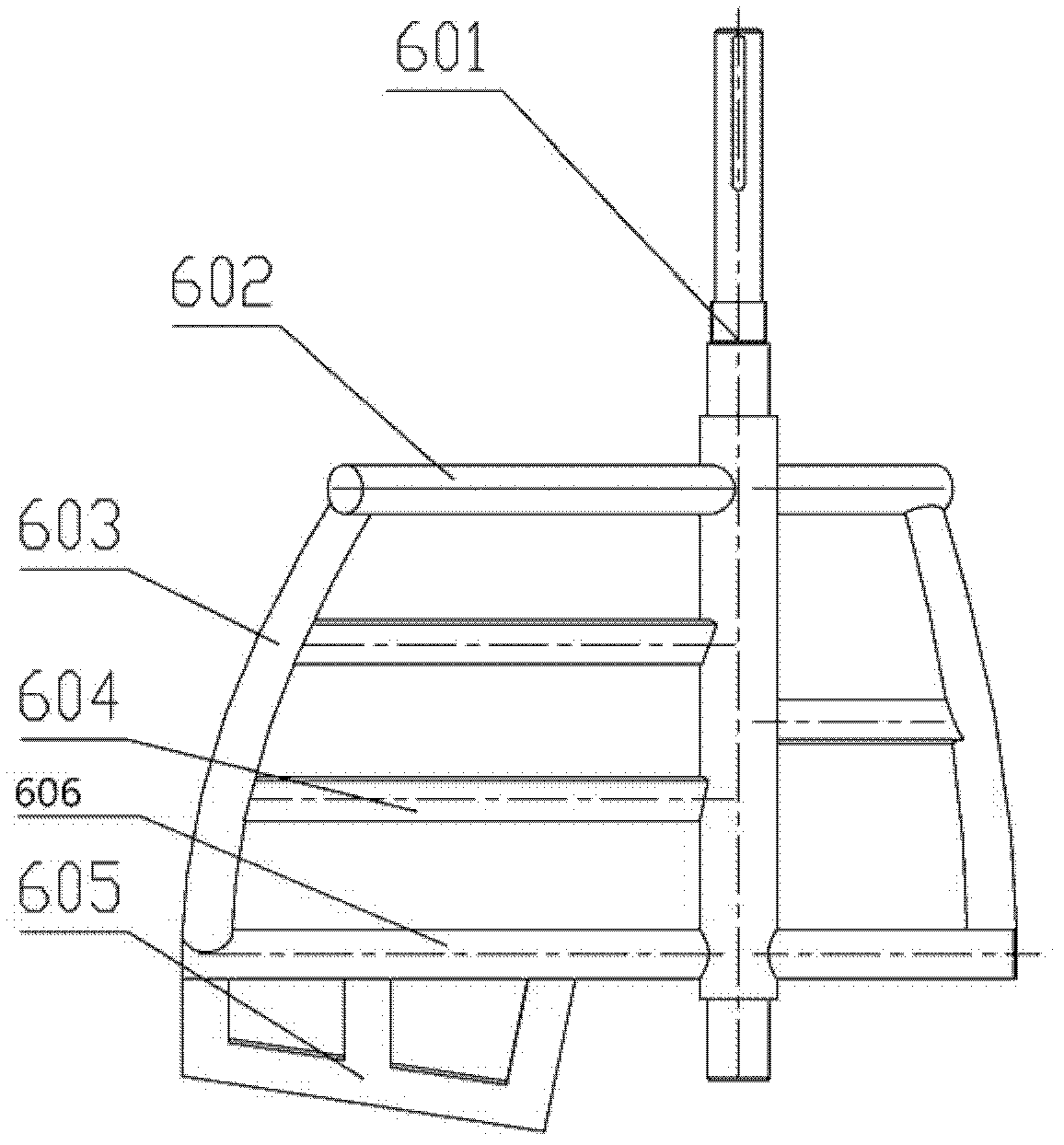

[0045] Such as figure 1 with figure 2As shown, the present invention provides a duck and goose feeding machine, comprising: a bucket 200, a filling device 400, a frame 100, a stirring device 300, a discharge pipe 18 and a pneumatic control circuit, and the pneumatic control circuit is connected to the filling device 400 , used to drive and control the filling device 400 to perform suction and extruding actions. The filling device 400 and the discharge pipe 18 are horizontally arranged below the material barrel 200. The upper part of the material barrel 200 is cylindrical, and the lower part is conical. The material opening is arranged at the lower end of the conical material barrel 200, and the suction end of the filler device 400 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com