Shaping clamping fixture for motor coil

A mold and wire bag technology, which is applied in the field of combined elastic motor wire bag shaping mold, can solve the problems of easy damage, affecting product quality, wire bag inner cavity size, shape can not meet the predetermined requirements, etc., to ensure product quality , to prevent the effect of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

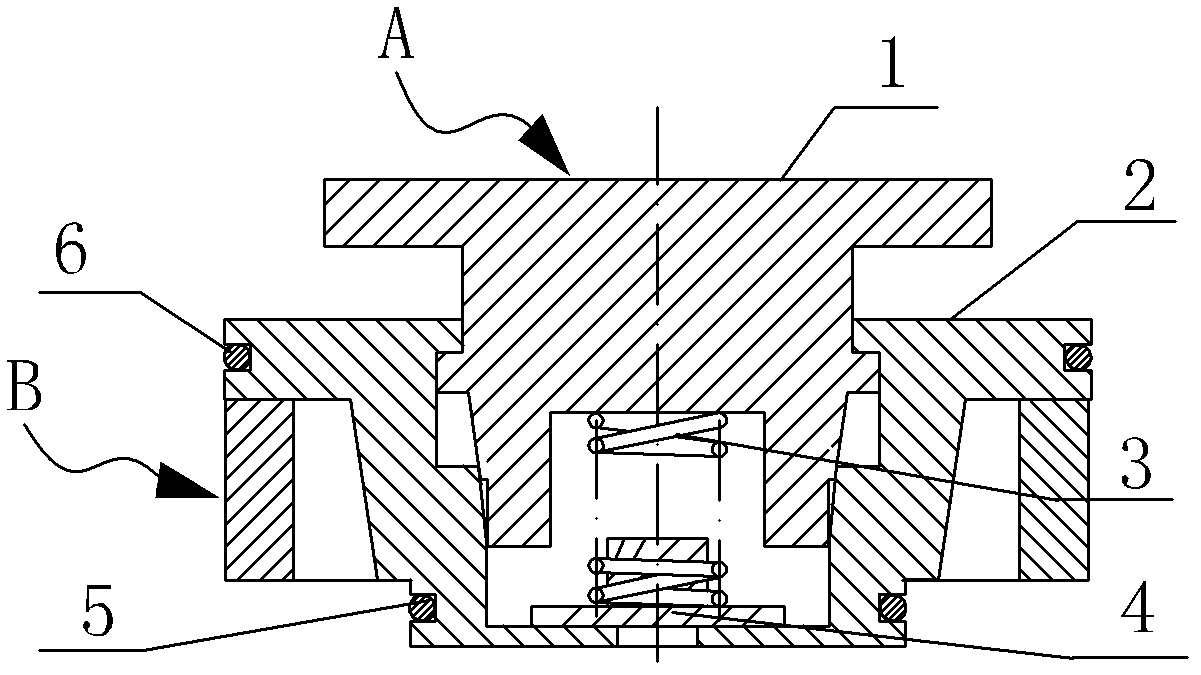

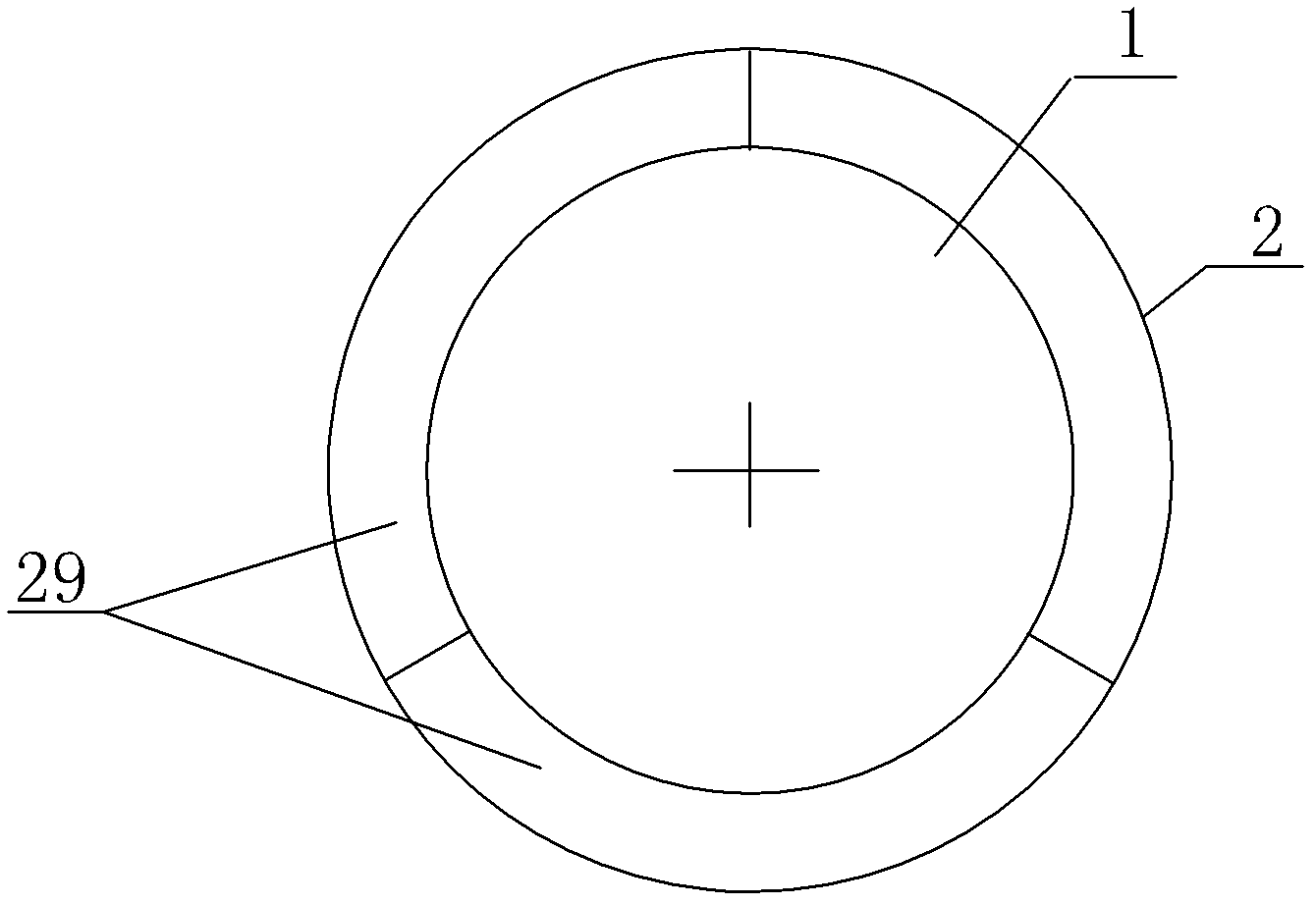

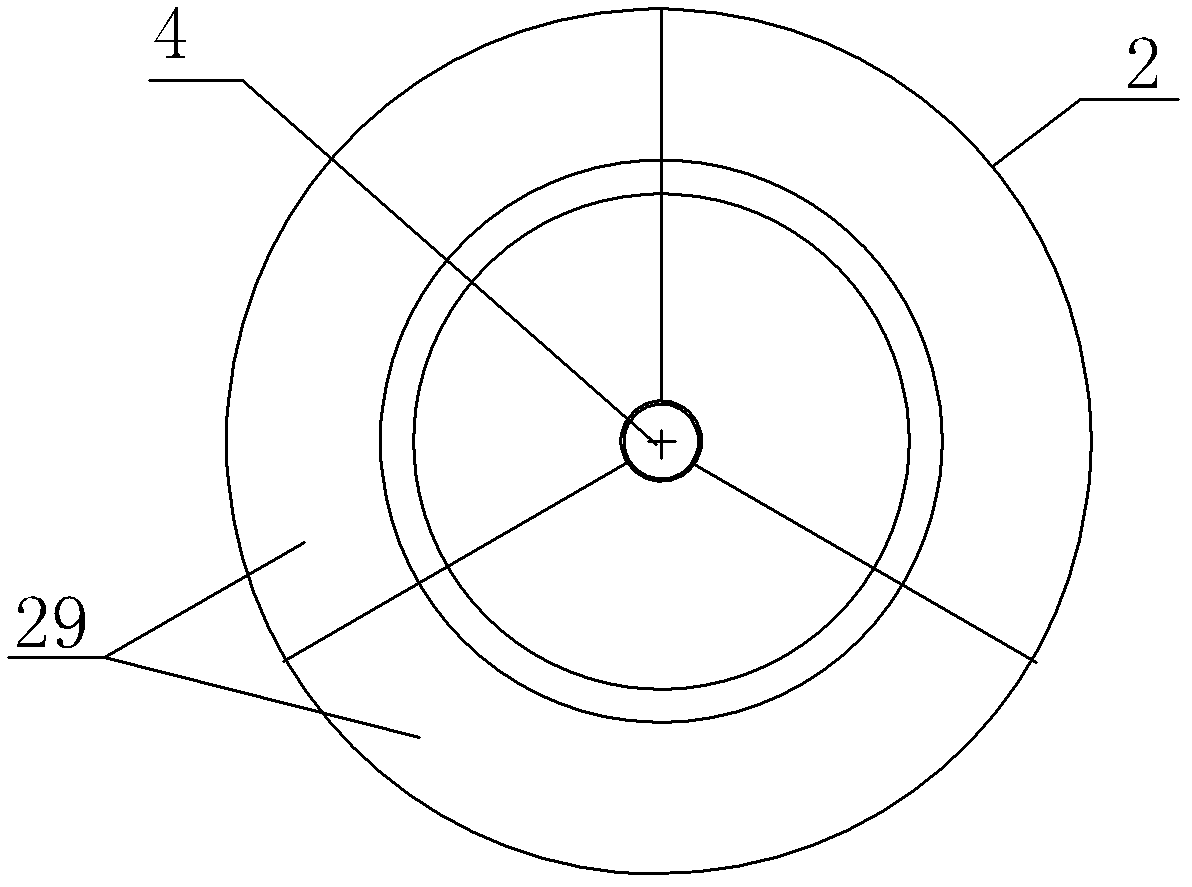

[0018] Figure 1 to Figure 6 It shows a motor wire package shaping mold, Figure 7 is its application diagram. As shown in the figure, the motor wire package shaping tool includes an external shaping tool B and an inner cavity shaping tool A. A is an expansion pressure body for expanding and pressing the inner cavity and the top surface of the end of the wire package of the above-mentioned motor. Elastic ring composition. The above-mentioned expansion sleeve 2 is composed of a top pressure plate 28 part coaxially provided with an expansion core via hole 21 in the center, a middle inverted conical sleeve body 27 part and a bottom cylindrical positioning ferrule 26 part. The expansion core 1 and The expansion sleeve 2 is arranged coaxially, and its top is the force-applying pressure plate 11 above the above-mentioned force-bearing pressure plate 28, and the expansion core body at the lower part of the force-applying pressure plate can move up and down through the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com