Distributed power supply system of relay protection device

A technology of relay protection device and power supply system, applied in the direction of emergency power supply protection, etc., can solve the problems of increasingly high requirements, long development cycle, and partial influence of double plug-in sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in further detail below according to the accompanying drawings.

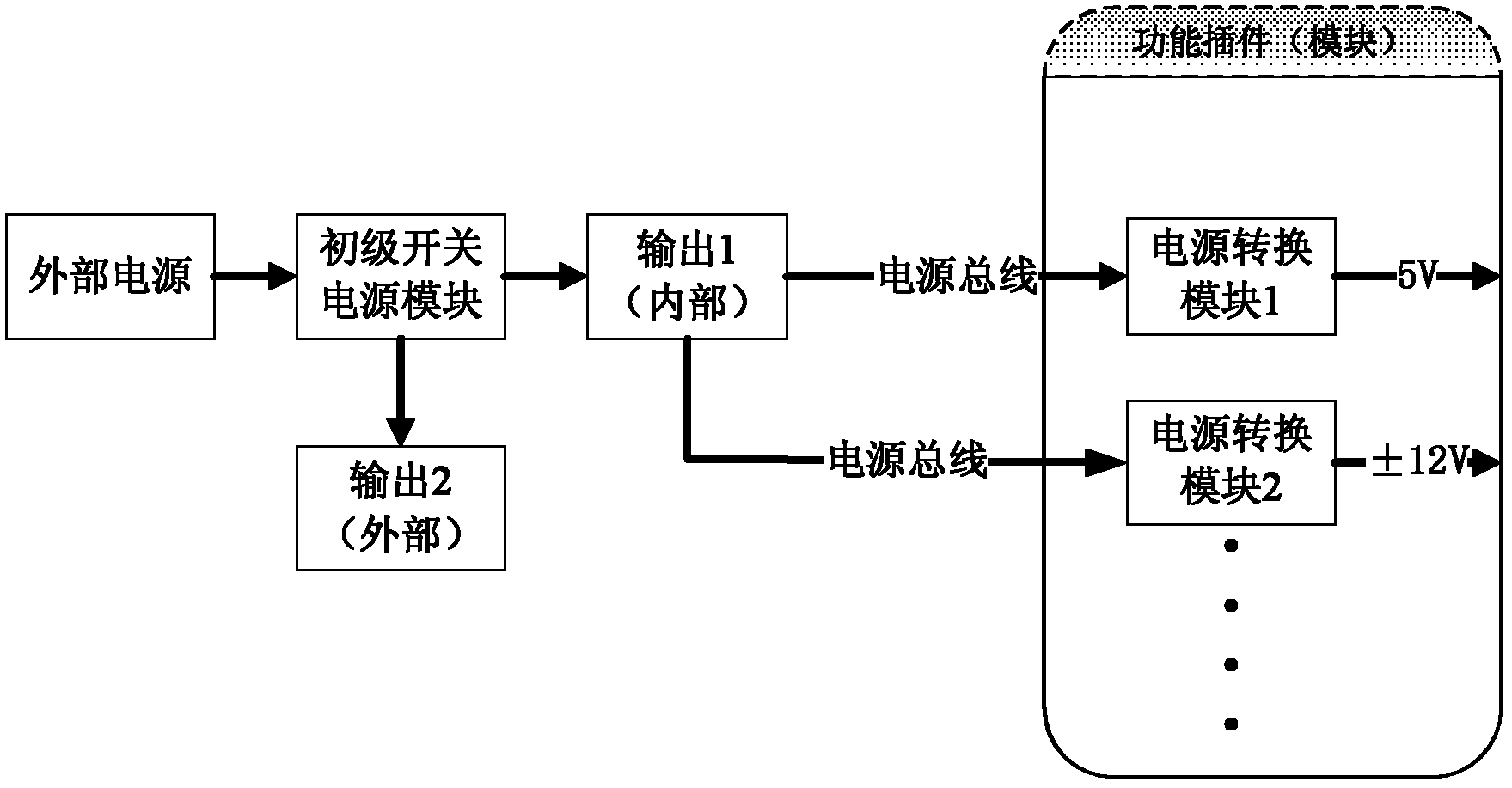

[0030] The invention discloses a distributed power supply system for a relay protection device. The power supply system includes a primary power supply module, a power bus, and a power conversion module. The system is constituted as follows: figure 1 shown.

[0031] The primary power module converts the external input voltage into the required power supply inside the device; in order to improve the power conversion efficiency, the primary power module is designed as a switch type, and its input voltage can be DC220V, DC110V, DC48V and other DC voltages, It can also be an AC voltage. The input end of the module is externally connected to an external power supply, and two mutually isolated power outputs are designed internally, both of which are 24VDC; among them, the first output is introduced into the power bus, and output to each function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com