One-pulling-two expansion and construction process of large-section lead

A technology of construction technology and large cross-section, applied in the direction of cable laying equipment, etc., can solve the problems of inability to guarantee the safety and construction quality of the construction process, and achieve the effect of ensuring the quality of wire-laying construction, high social economy, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

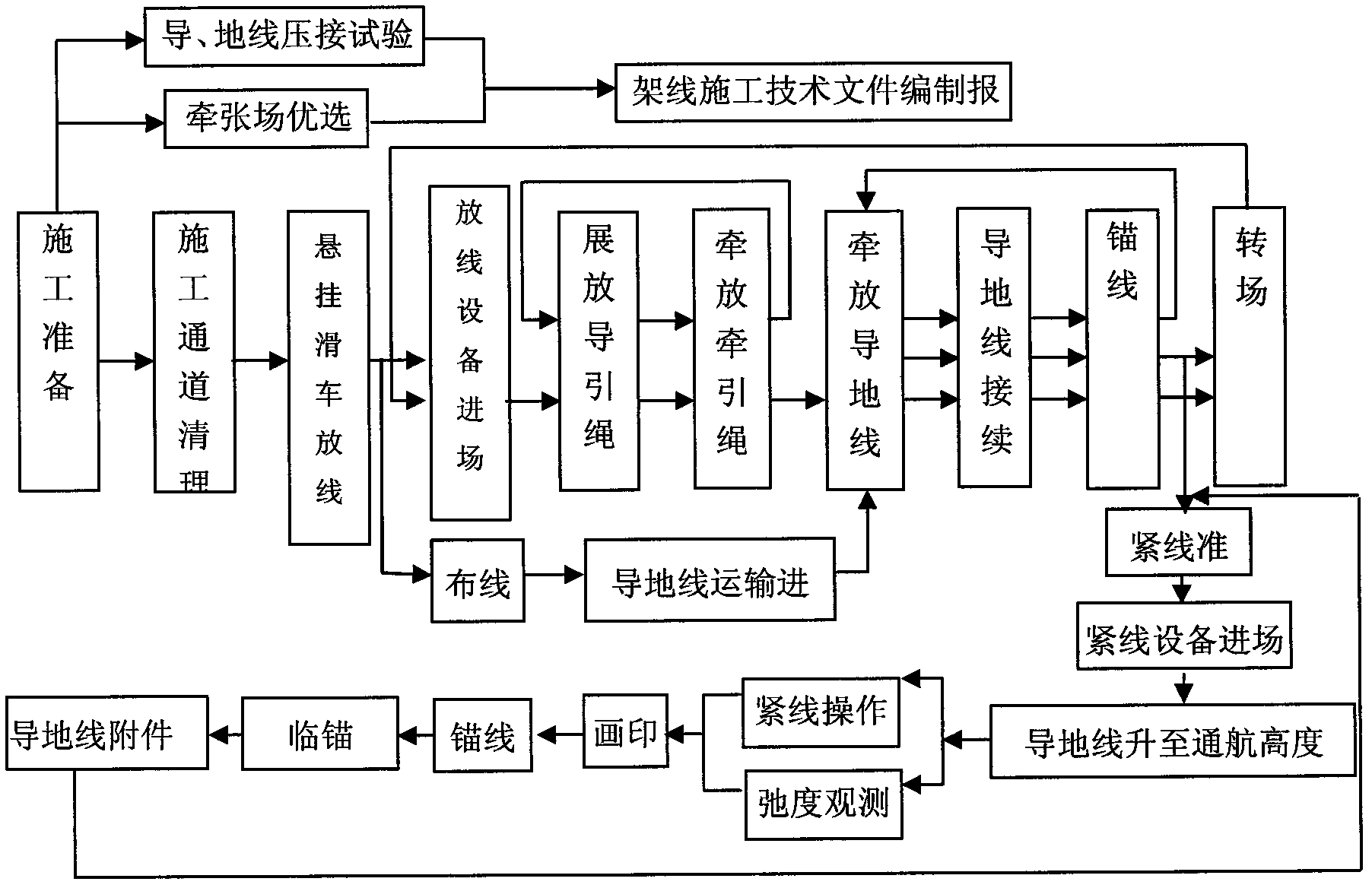

[0024] The specific technical scheme of the present invention is illustrated by the test of tension stringing of large-section conductors in ±800kV UHV DC transmission lines.

[0025] 1. Before construction

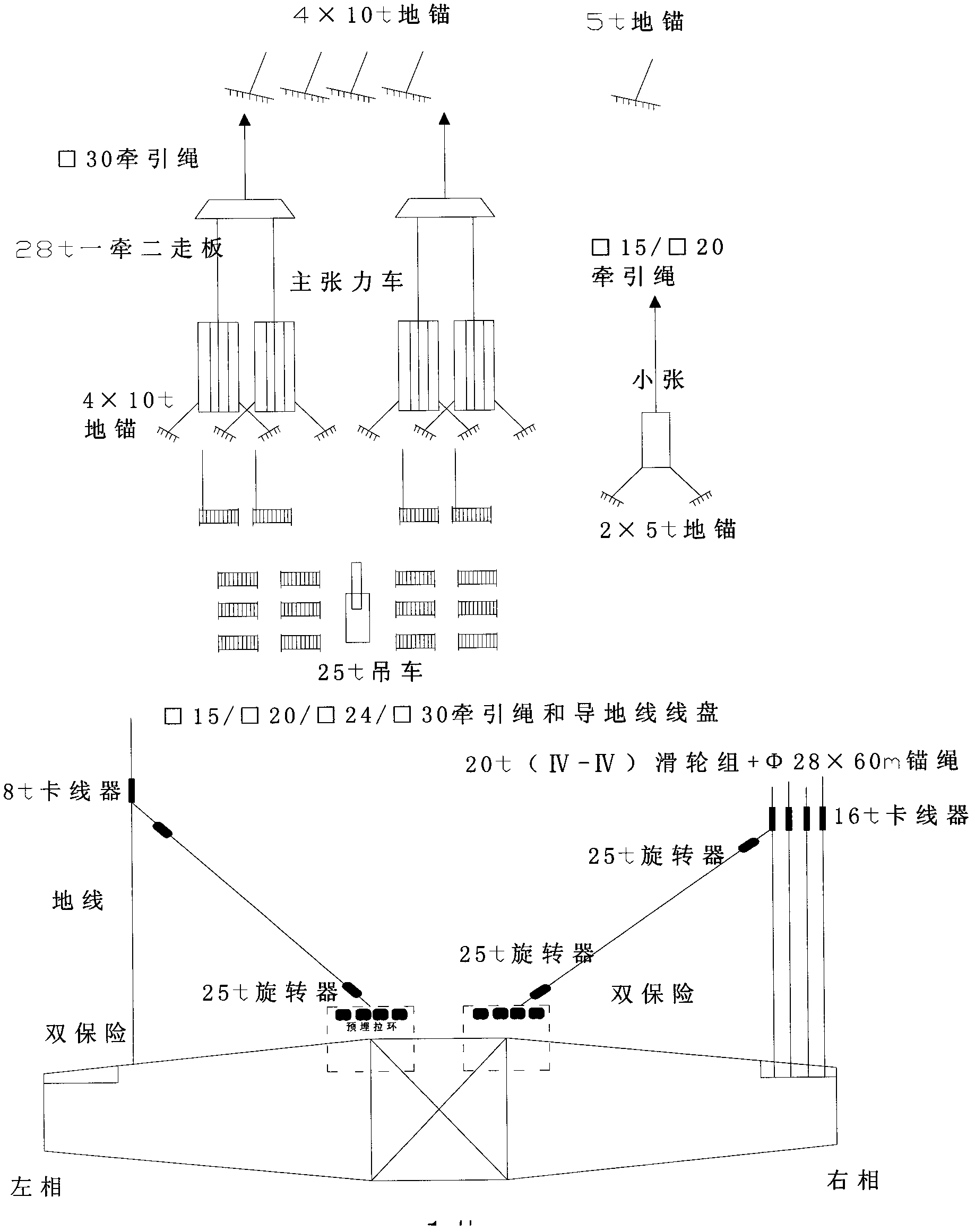

[0026] According to the number of line construction bids, path length, number of iron towers, spanning distance, type and parameters of wires, select the specifications and models of ground wires, specifications and parameters of traction ropes and guide ropes, and calculate the various parameters used for setting out wires. The parameters of anti-twist wire ropes of different specifications, select the type and quantity of the main equipment and tools for "one pull 2" wire erection construction, and choose the "one pull 2" deployment plan, that is, use one tractor to connect with two sets of wire ropes. Cooperate with the tension machine, use the "one pull 2" walking board and the three-wheel pay-off block to cooperate with the pay-off, comprehensively consider various f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com