Device for measuring thermal conductivity of vacuum glass

A technology of vacuum glass and measuring device, applied in the direction of thermal development of materials, etc., can solve the problems of unreachable detection board, lack of accuracy of detection result data, bad top, etc., to improve reliability and accuracy, improve reliability and easy operation. performance, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

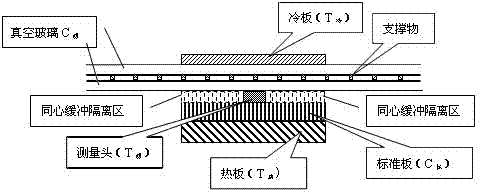

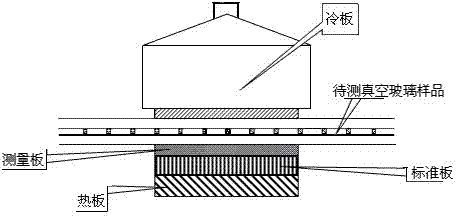

Method used

Image

Examples

Embodiment Construction

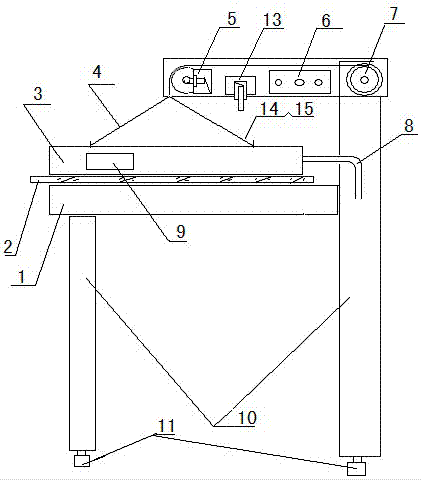

[0029] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] see image 3 , a vacuum glass thermal conductivity measurement device, including a bracket 10, a horizontal hot plate 1 is arranged on the left side of the bracket 10, a cold plate 3 is arranged above the hot plate 1, and the cold plate 3 communicates with the cooling hose 8, The upper part of the cold plate 3 bypasses the movable pulley on the vertically rising limit switch 5 through three soft ropes and is connected with the electric wheel 7. The displacement of the cold plate 3 in the vertical direction is also limited by the descending limit switch 13 vertically arranged on the crossbeam 12. , The beam 12 is also provided with a control device 6, and the electric wheel 7 is connected with the driving motor. The control device 6 realizes signal processing and issues corresponding instructions as req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com