Moisture detecting method for overheated steam of steam pipeline of turbine

A technology for detecting sensors and steam pipelines, which is applied in the direction of material analysis, instruments, and measuring devices by optical means, can solve the problems of safety, failure to monitor the moisture of superheated steam, hidden dangers, etc., and achieves low production cost and separation of steam and water. Good effect and easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

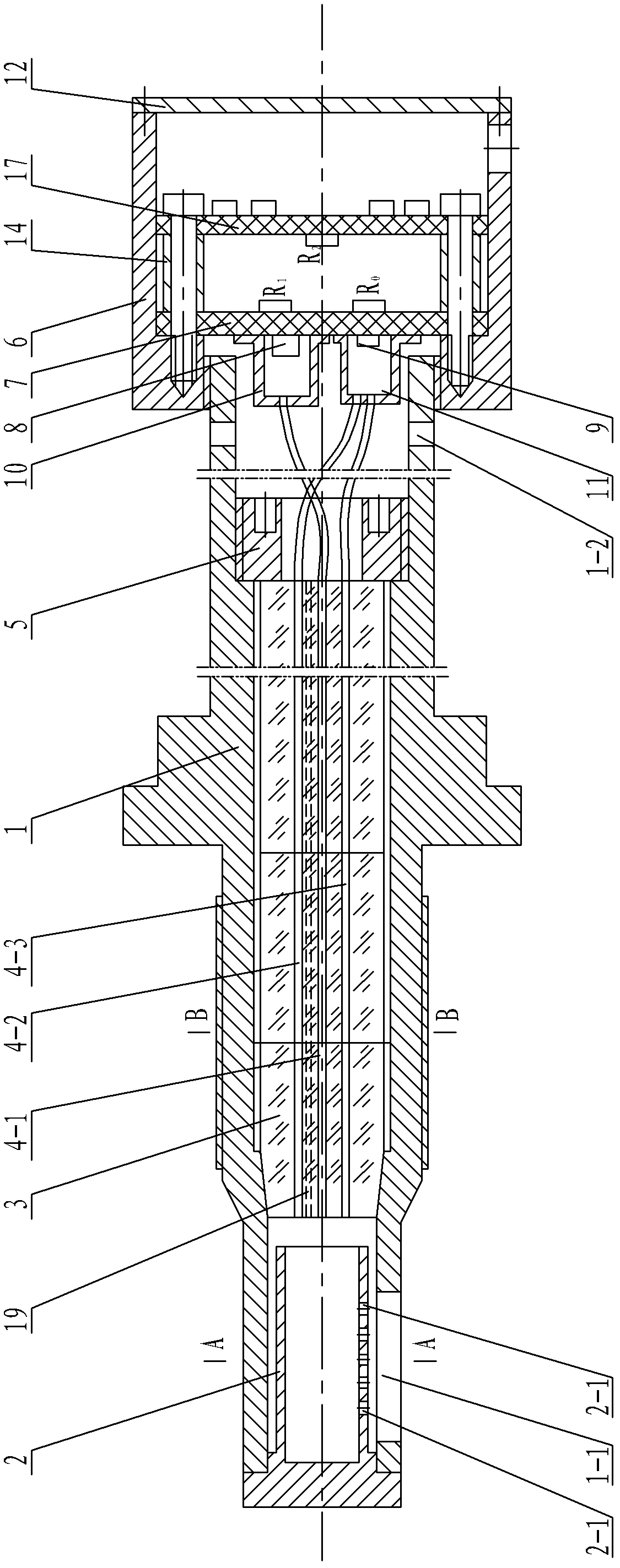

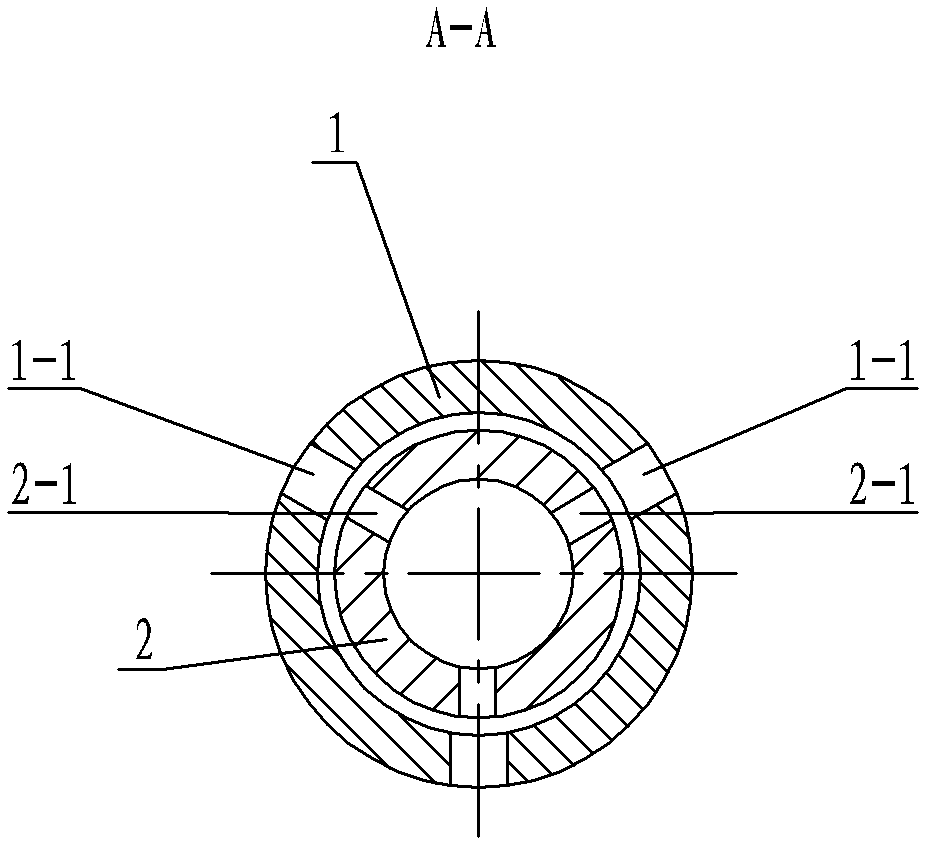

[0009] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, the steam turbine steam pipeline superheated steam moisture detection sensor of this embodiment includes a circular tubular shell 1, a short pipe 2, an insulating cylinder 3, a first optical fiber 4-1, a second optical fiber 4-2, and a third optical fiber 4 -3, wire ring 5, cylindrical metal box 6, front insulating plate 7, light-emitting diode 8, photocell 9, first metal cover 10, second metal cover 11, box cover 12, rear insulating plate 17, measuring resistance R 0 , compensation resistor R 1 , adjustable resistance R 2 , the first pair of terminals 16 and the second pair of terminals 18;

[0010] The short tube 2 is a short tube with one end closed, the open section of the short tube 2 is inserted into the front end of the round tubular shell 1, the closed end of the short tube 2 is fixedly connected with the round tubular shell 1, and the inner end surface of the closed end ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 This embodiment will be described. The short pipe 2 of this embodiment is made of stainless steel. So set, the service life is longer. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, each exhaust hole 2-1 of this embodiment includes 5 small holes, the diameter of which is 4 mm, and the center distance between the holes is 8 mm. With such setting, the separation effect of soda and water is better. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com