Control device for cover of electric induction furnace

A control device and furnace cover technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

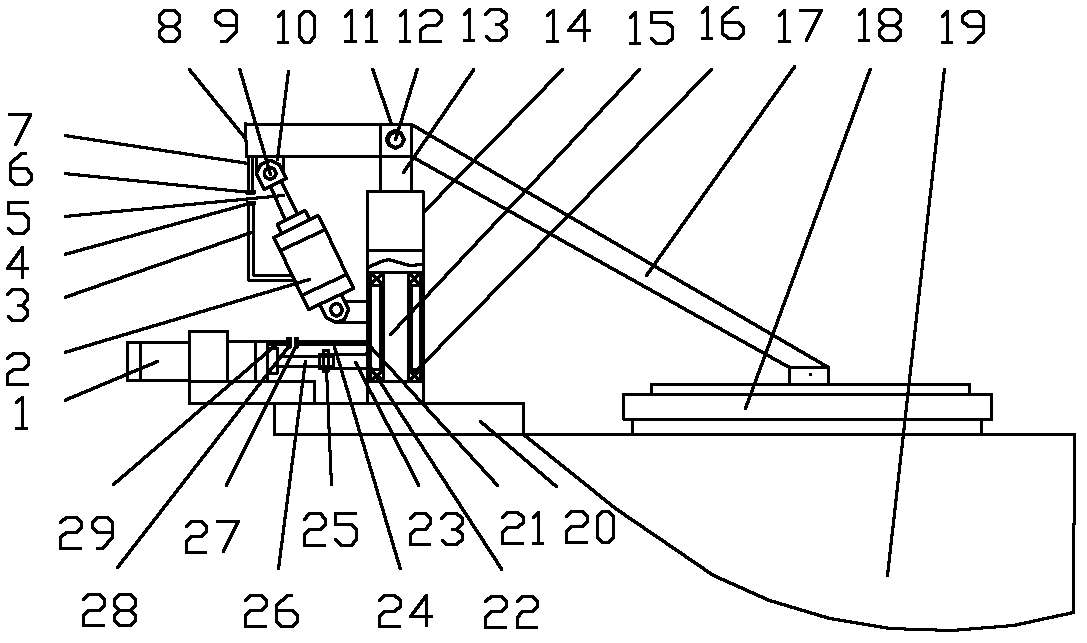

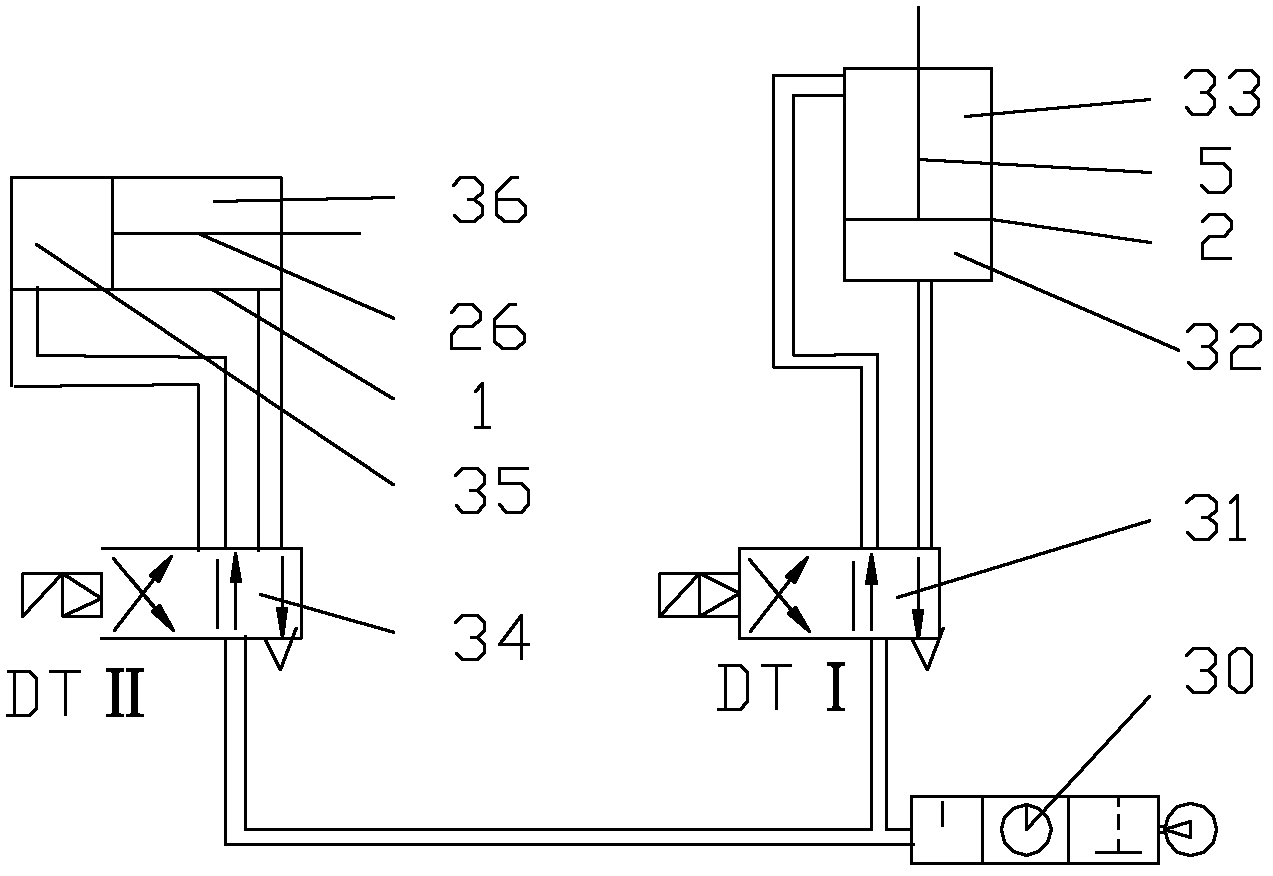

[0026] The embodiments shown in the accompanying drawings are as follows: a pneumatic control device for the furnace cover of an induction electric furnace.

[0027] like figure 1 , figure 2 Shown: frame 20 is installed on one side of body of heater 19. Vertical shaft 15 is housed in framework 20 middle parts. A sleeve 14 is sheathed on the outside of the vertical shaft 15 . A bearing 16 is installed between the vertical shaft 15 and the sleeve 14 , and the sleeve 14 can rotate around the vertical shaft 15 through the bearing 16 . A connecting rod I13 is welded on the upper end of the sleeve 14, and the upper part of the connecting rod I13 is movably connected with the connecting rod 12 through a pin shaft I12. One end of the connecting rod 12 is an inclined oblique rod 17, and the end of the inclined oblique rod 17 is fixedly connected with the large furnace cover 18. The other end of the connecting rod 12 is a transverse connecting rod 8 . The lower end of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com