Supporter exchanging method for stage construction basement using cast-in-situ bored piles as separation palisade

A technology for bored piles and basements, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of high support replacement cost and troublesome construction, and achieve low support replacement cost, convenient construction, and support replacement effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

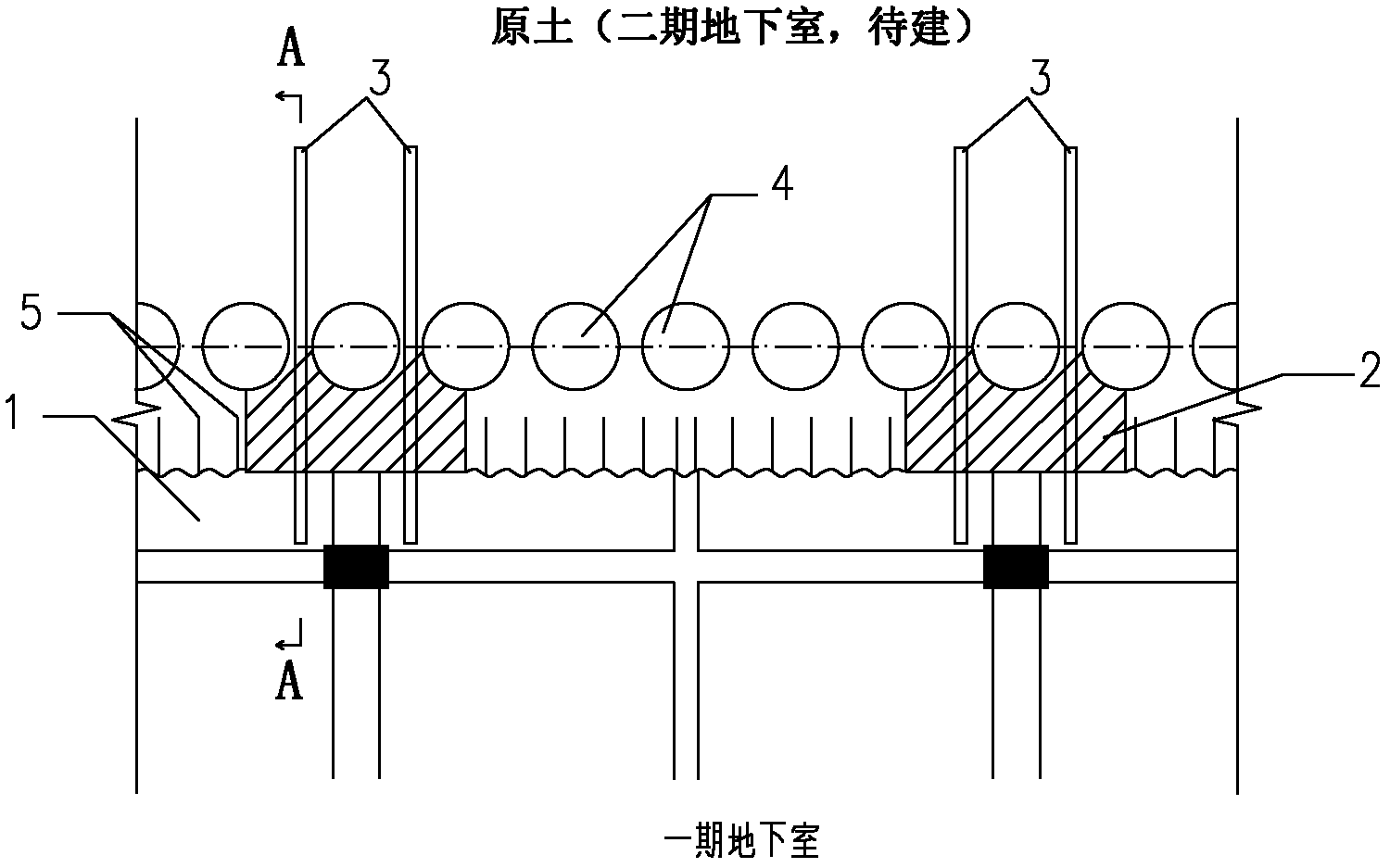

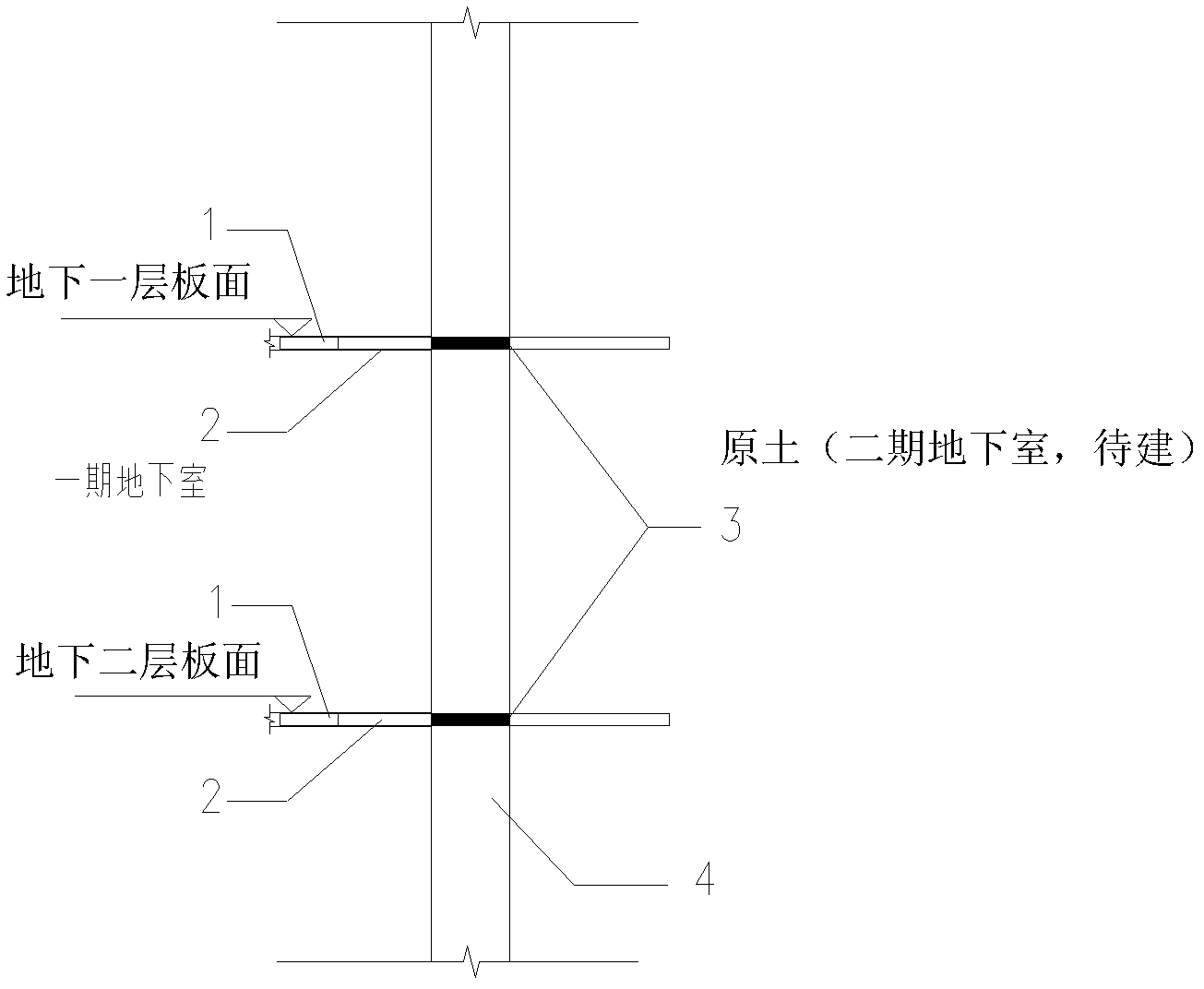

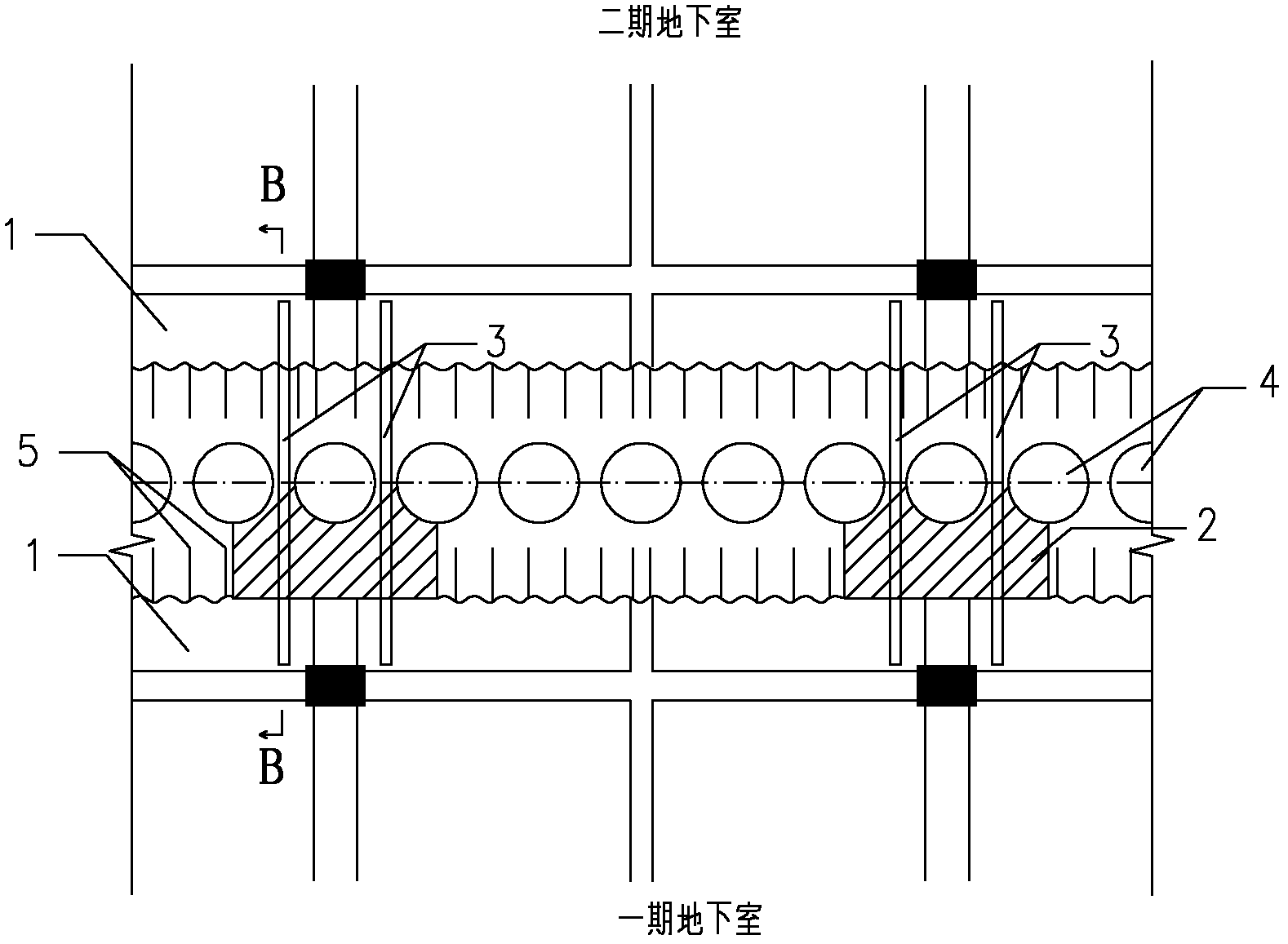

[0019] Such as Figure 1 to Figure 6 Shown, a kind of bored cast-in-situ pile is used as the method for changing the support of the basement in staged construction, which comprises the following steps:

[0020] Step 1: Construct a separate enclosure structure with bored piles 4 as the main body between the first-stage basement and the second-stage basement, intersperse the supporting steel 3 between adjacent bored piles 4, and pour the basement of the first-stage basement For the floor 1, reserve the connecting steel bar 5 on the side close to the bored pile 4, and embed one end of the supporting steel 3 into the basement floor 1 and the force transmission belt 2 of the first-phase basement;

[0021] Step 2: When pouring the basement slab 1 of the second-phase basement, reserve the connecting steel bar 5 on the side close to the bored pile 4, and bury the other end of the supporting steel 3 in the basement slab 1 of the second-phase basement;

[0022] Step 3: Remove the bored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com