Stage construction basement support change method using underground continuous wall as separation containment

A technology for underground diaphragm walls and basements, which can be used in artificial islands, water conservancy projects, underwater structures, etc., and can solve problems such as construction troubles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

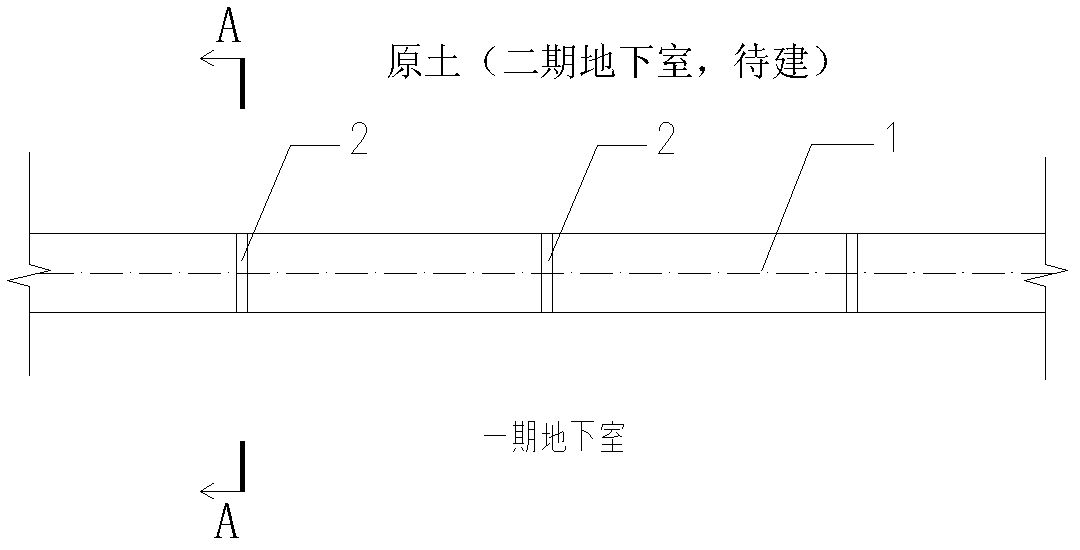

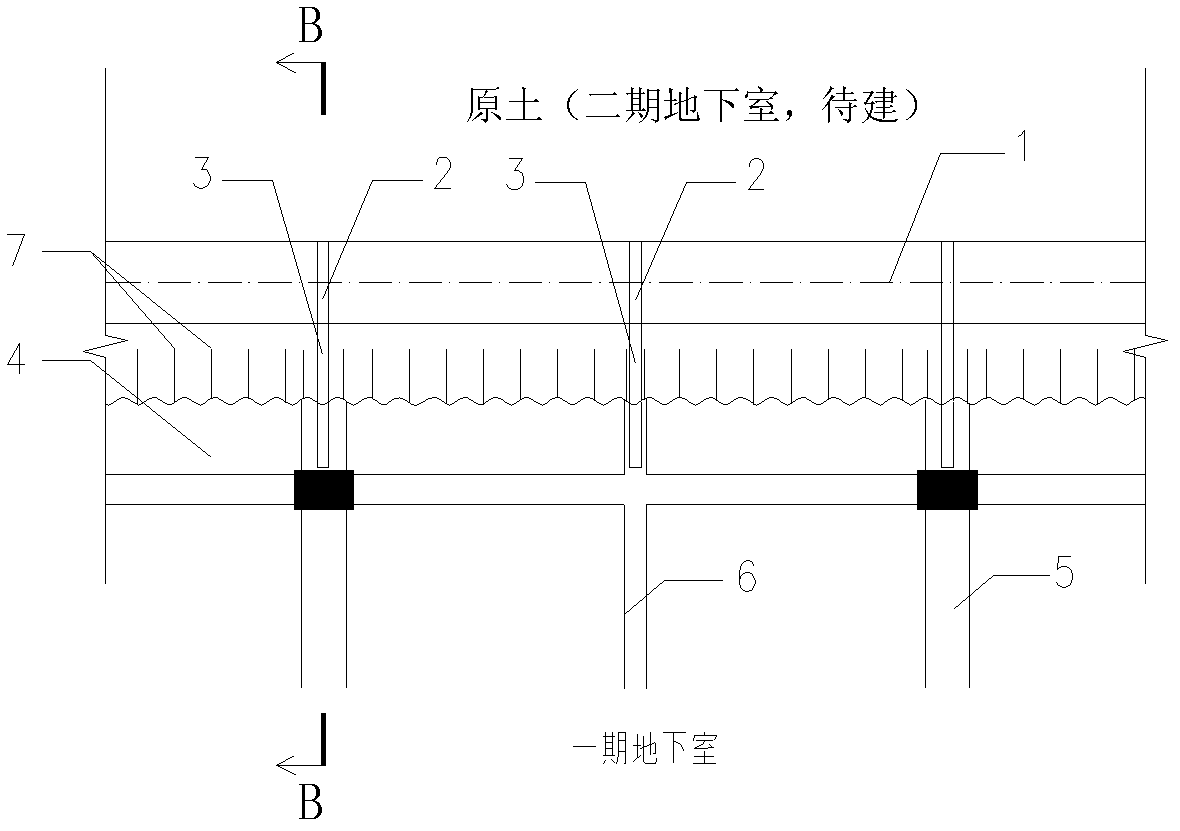

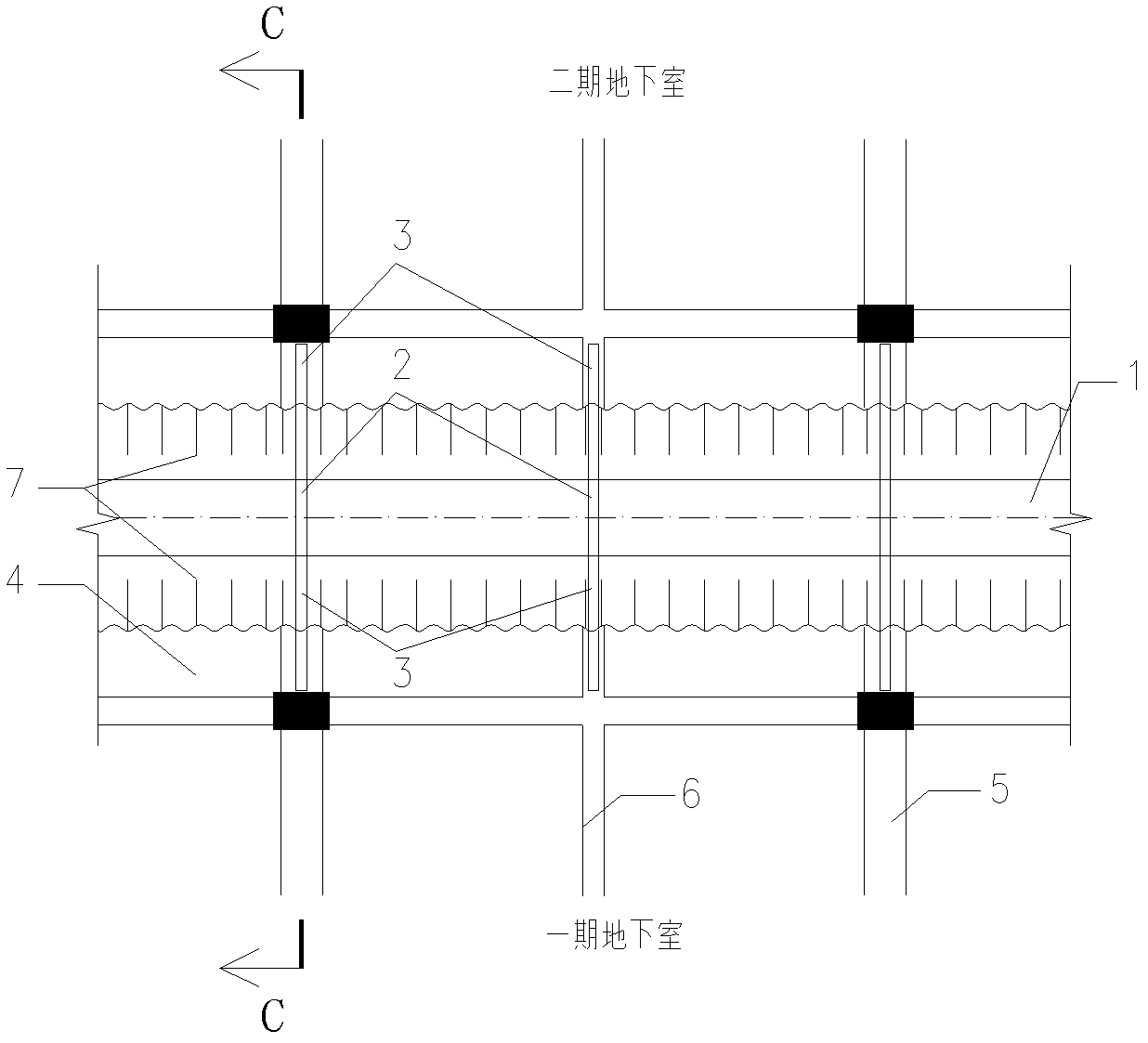

[0019] Such as Figure 1 to Figure 8 Shown, a kind of underground diaphragm wall is used as the basement replacement support method of staged construction, comprising the following steps:

[0020] Step 1: Construct a separate enclosure structure with the underground diaphragm wall 1 as the main body between the basement of the first phase and the basement of the second phase, and pre-embed the main beam 5 and the secondary beam 6 of the floor structure on the underground diaphragm wall 1. Embedded shaped steel 2, the thickness of the embedded shaped steel 2 is equal to the wall thickness of the underground diaphragm wall 1;

[0021] Step 2: During the first-phase basement replacement construction, weld the same type of replacement steel 3 at one end of the pre-embedded steel 2, and pour the other end of the replacement steel 3 into the basement floor 4 of the first-phase basement, and the basement floor slab of the first-phase basement. 4. Reserve the connecting steel bar 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com