Knocking device for removing carbon deposition from coal gasifier

A technology for coal gasification and carbon deposition, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry. Easy to install, long service life, prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

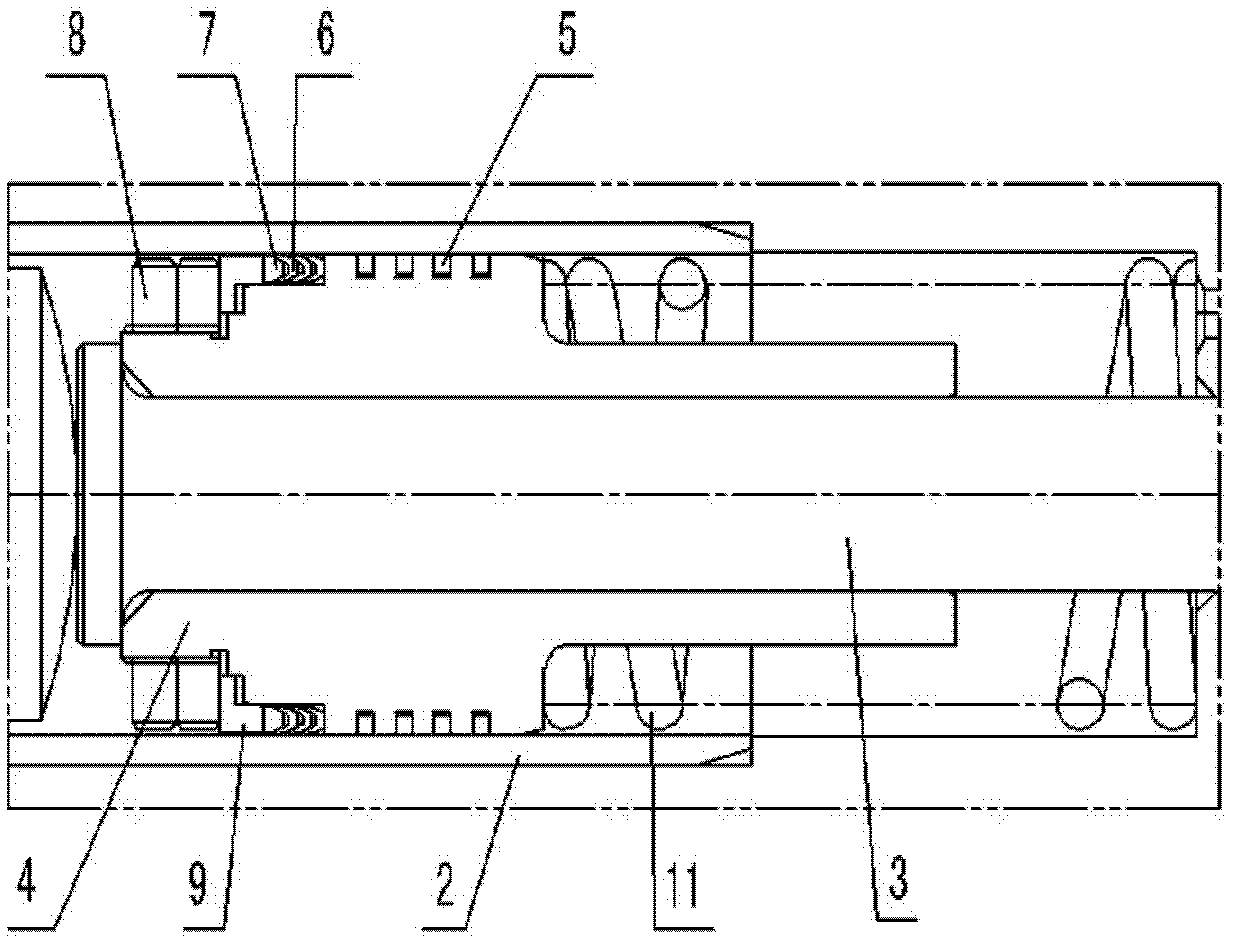

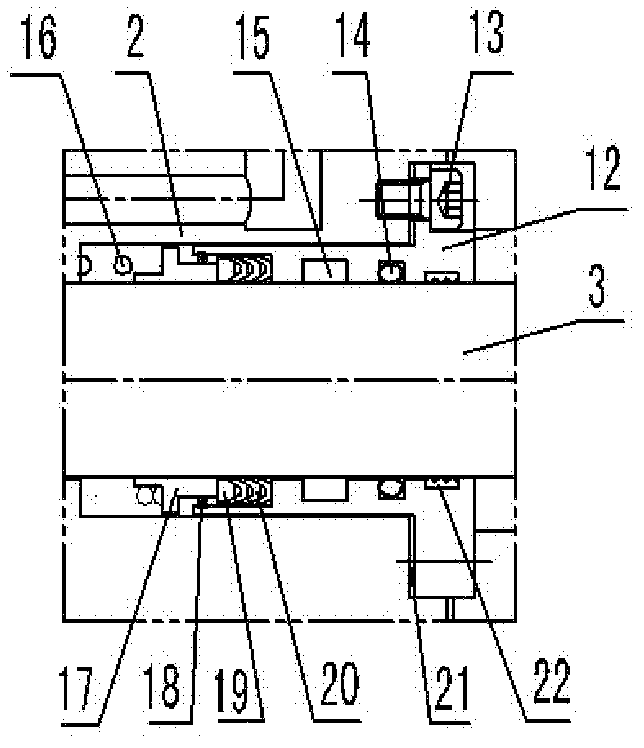

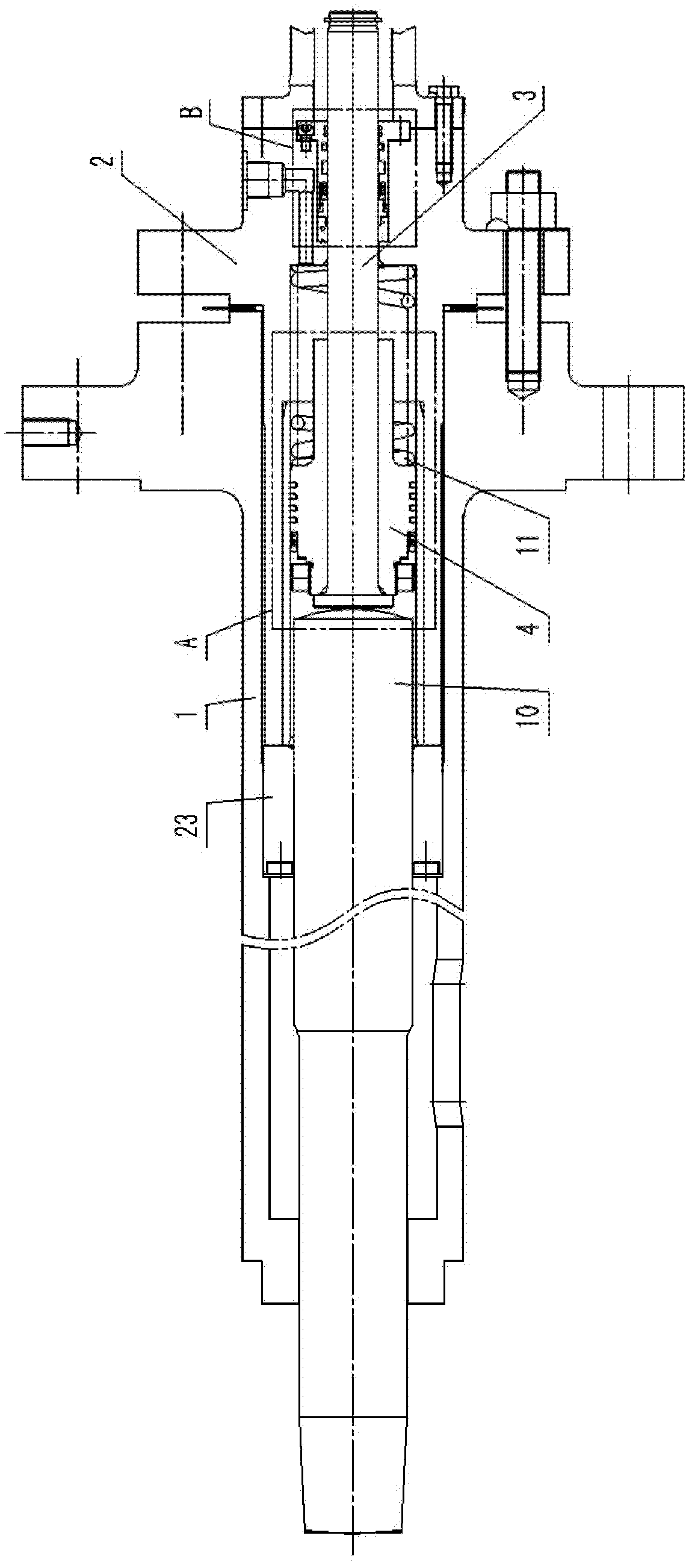

[0019] see figure 1 , figure 2 and image 3 The coal gasification furnace carbon deposition knocking device in this embodiment includes a support body 1, a guide sleeve 2 statically connected with the support body 1, a pressure sleeve 12 connected to the end of the guide sleeve 2 by a screw 13, and a piston rod. 3. The piston 4 set on the piston rod 3 is pre-tightened by the spring 11 on the piston 4 set on the piston rod 3, so that the end surface of the hammer body 10 supported by the support body 1 is in contact with the rod end of the piston rod 3 , the medium is filtered by the filter device 23 installed in the support body 1 .

[0020] like figure 1 and image 3 As shown, the piston rod seal B in this embodiment is a cartridge seal structure installed in the pressure sleeve 12, and the pressure sleeve 12 and the guide sleeve 2 are sealed by the end face sealing gasket 21; the overall seal of the piston rod seal B In the structure, an O-shaped sealing ring 14 and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap