General chassis of track robot

A crawler robot and chassis technology, which is applied to crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of increased weight of the whole machine, cumbersome structure, slow progress, etc., and achieves low manufacturing cost, good workmanship and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

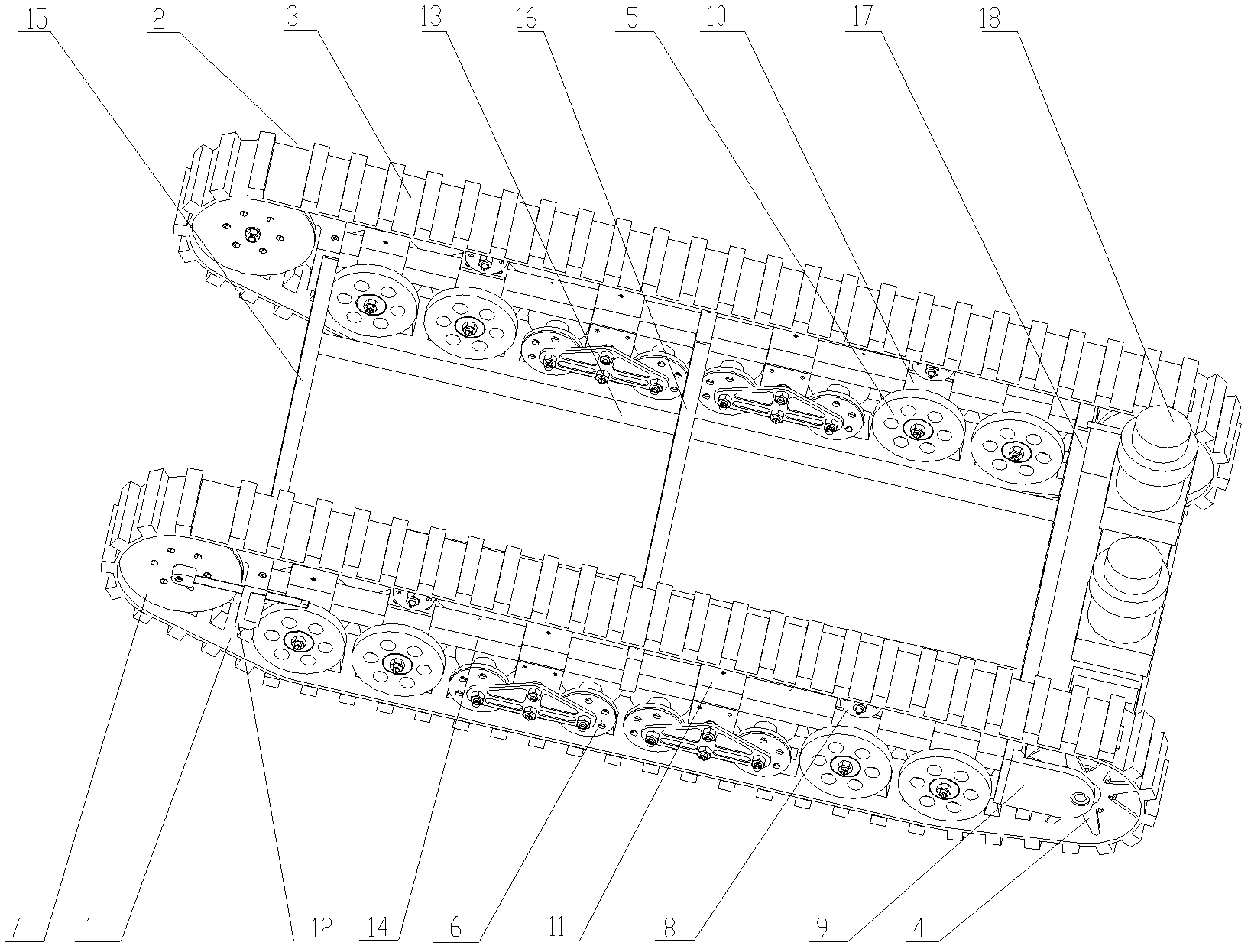

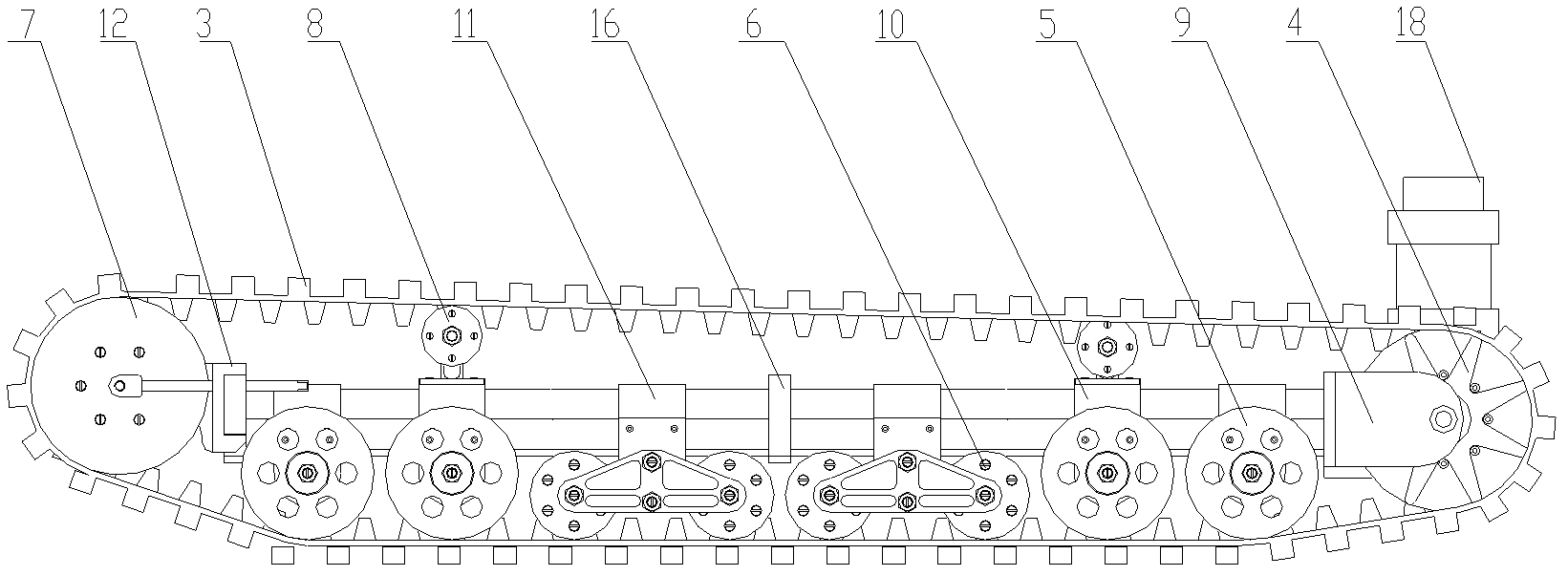

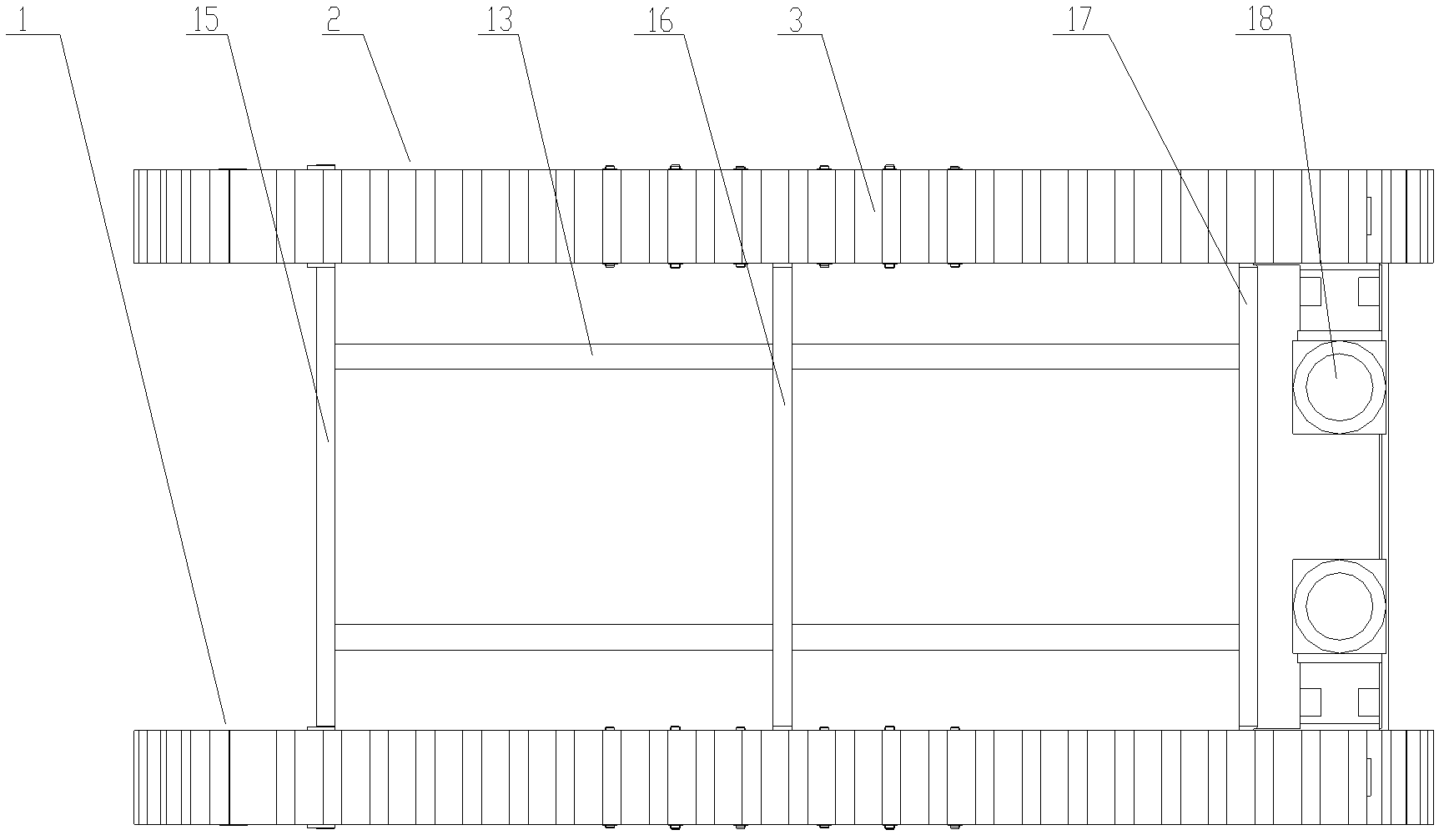

[0028] Such as Figure 1~6 As shown, the general chassis of the crawler robot of the present invention has a left assembly 1 and a right assembly 2 with the same structure and arranged symmetrically. Both the left assembly 1 and the right assembly 2 include a set of driving wheel parts 4, a set of tension wheel parts 7, four sets of supporting wheel parts 5, two sets of floating wheel parts 6, and two sets of support pulley parts 8, The driving wheel part 4, the tension wheel part 7, the supporting wheel part 5 and the floating wheel part 6 are respectively installed on the corresponding driving wheel part seat 9, the tension wheel part seat 12, the supporting wheel part seat 10 and On the floating wheel component base 11, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com