Car door anti-collision beam

A technology for car doors and anti-collision beams, applied to doors, vehicle parts, bumpers, etc., can solve the problems of anti-collision beam protection, unsatisfactory energy absorption effect, and failure to fundamentally solve the problems of door energy absorption and load transfer, etc. Problems, to achieve the effect of decentralized transmission and protection of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

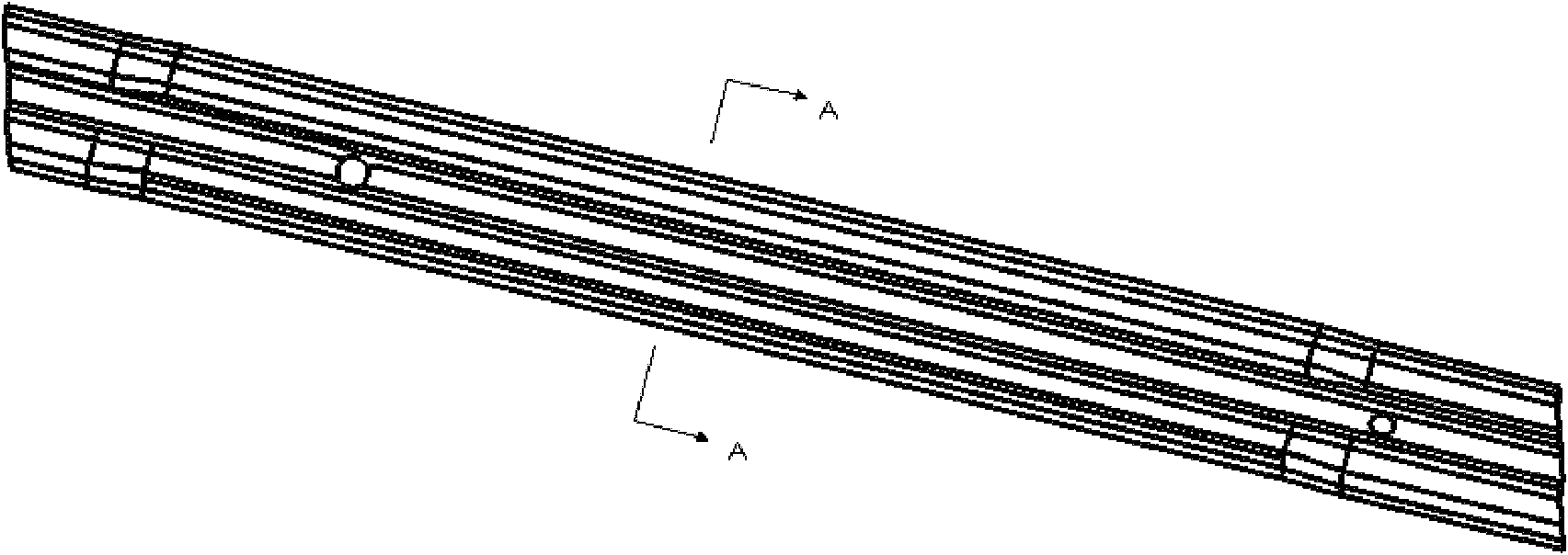

Image

Examples

Embodiment Construction

[0019] like figure 1 As shown, an automobile door anti-collision beam of the present invention includes a front door anti-collision beam 12 on the front door 1 and a rear door anti-collision beam 22 on the rear door 2 . The front door 1 includes a front door inner panel 11, the rear door 2 includes a rear door inner panel 21, and the front door anti-collision beam 12 is arranged obliquely from front to back, the front is high and the rear is low, and its front end is fixed on the top and bottom of the front end of the front door inner panel 11. Between the hinges and close to the position of the upper hinge, the rear end is fixed on the front door inner panel 11 near the lower end root 31 of the B-pillar 3, as figure 2 and image 3 As shown, the cross-section of the front door anti-collision beam 12 is a bow-shaped structure, or a double-hat structure. Compared with the prior art, the front door anti-collision beam 12 adopts a bow-shaped cross-section, and the energy absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com