Front safety girder and rear safety girder capable of realizing rigidity and flexibility combined efficient buffering energy absorption

A technology of rigid-flexible combination and automobile longitudinal beam, which is applied in the direction of bumper and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

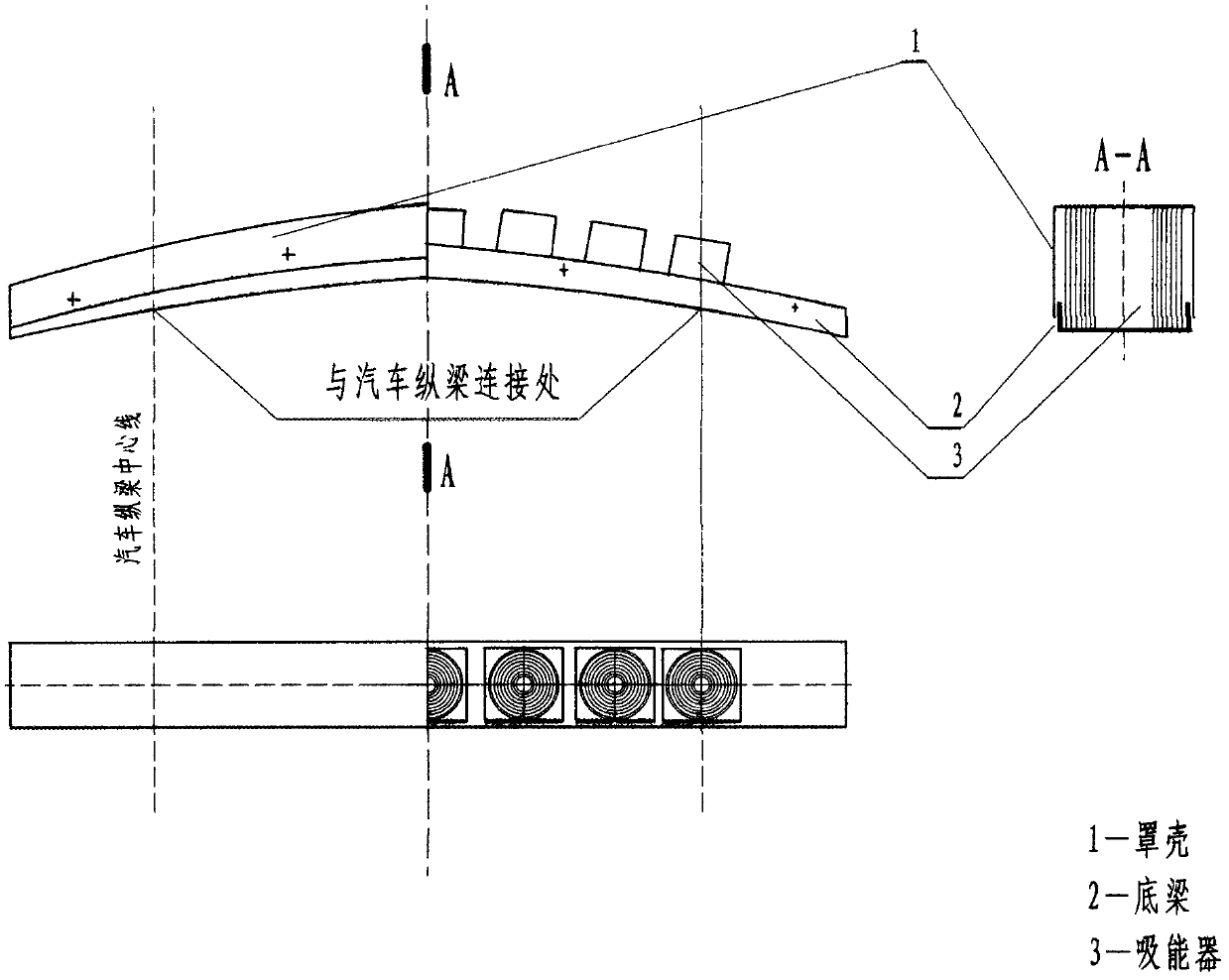

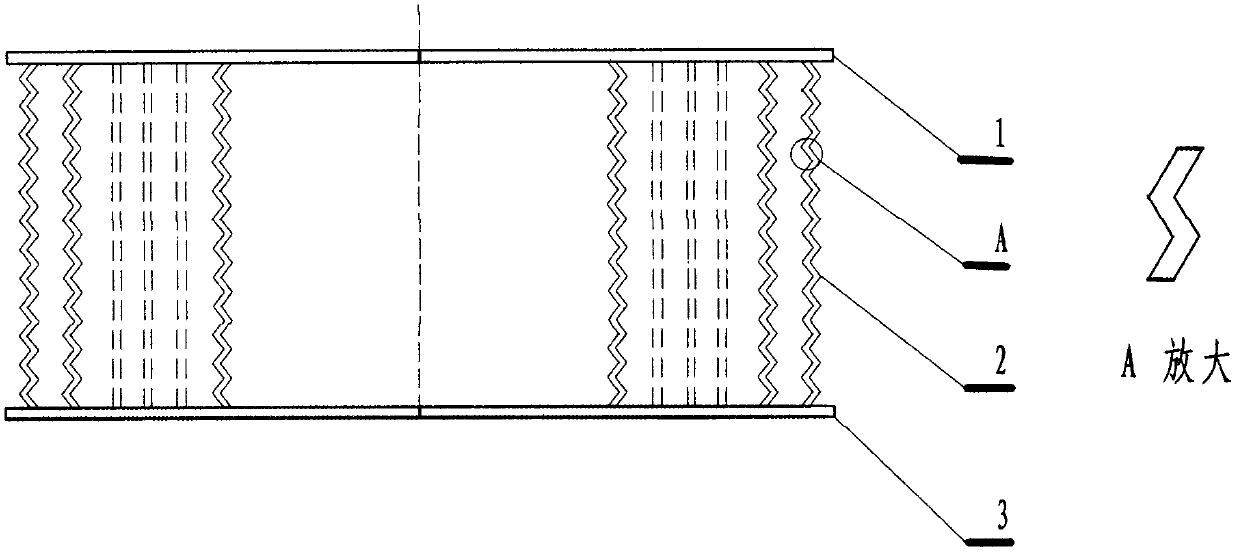

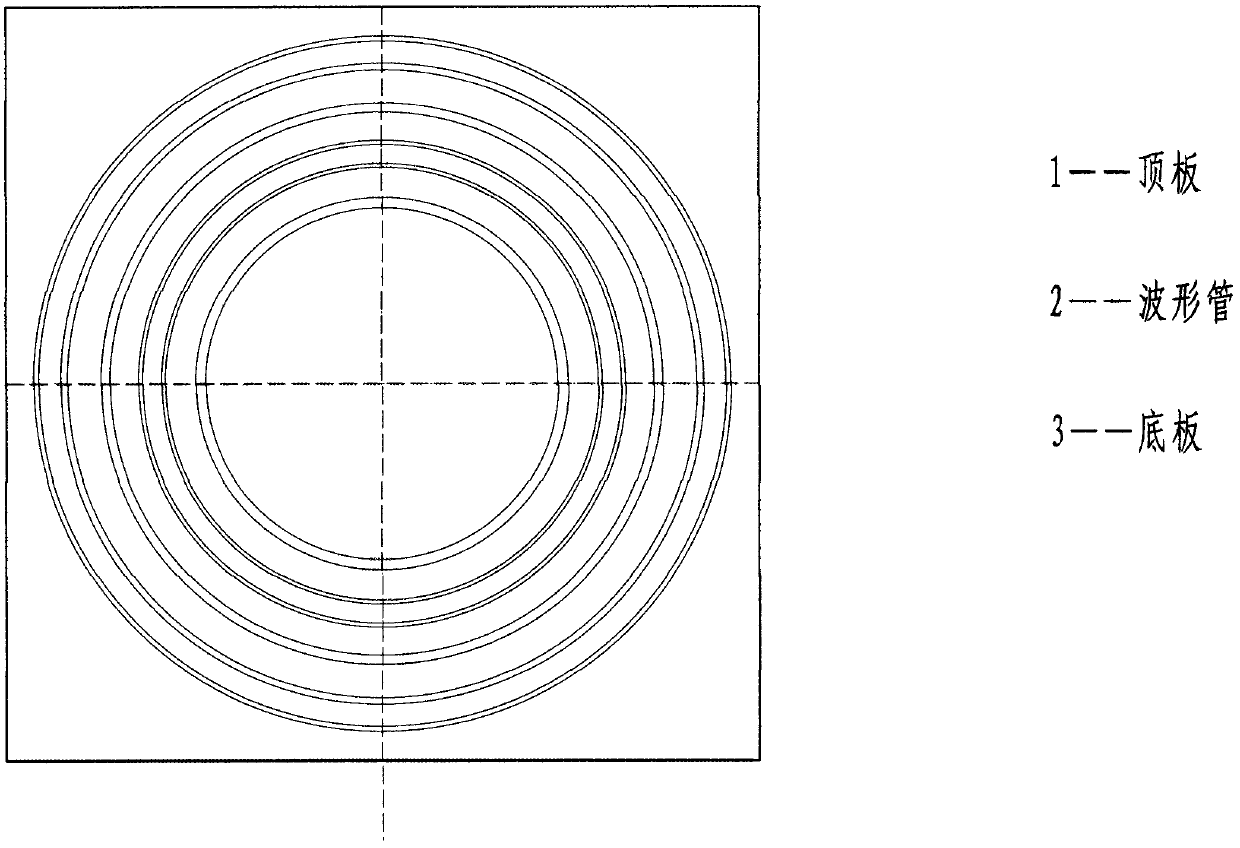

[0057] see Figure 1-3 According to the embodiment of the present invention, in the front safety beam and the rear safety beam of the automobile, according to the requirements and positions calculated by the design, the figure 2 The high-efficiency energy absorbers are welded and installed at the bottom of the front and rear sills. see figure 1 In the A-A sectional view, the centerline of the main energy absorber 3 should be installed facing the centerline of the front and rear longitudinal beams of the car, and the auxiliary energy absorbers should be installed in front of the centerline of the front and rear safety beams and evenly distributed on the left and right.

[0058] figure 1 The casings 1 of the front and rear safety beams in the middle A-A section should be installed on the bottom beam and the main and auxiliary energy absorbers, and cover the bottom beams and energy absorbers, but the casing and the bottom beam are flexibly connected, that is, the bottom beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com