Process flow for separating acid-insoluble substances in nitric phosphate production by chemical flocculence method

A technology of chemical flocculation and acid-insoluble substances, which is applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems that the solution cannot have a large flow, production discontinuity, etc., and achieve simple and flexible production process, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

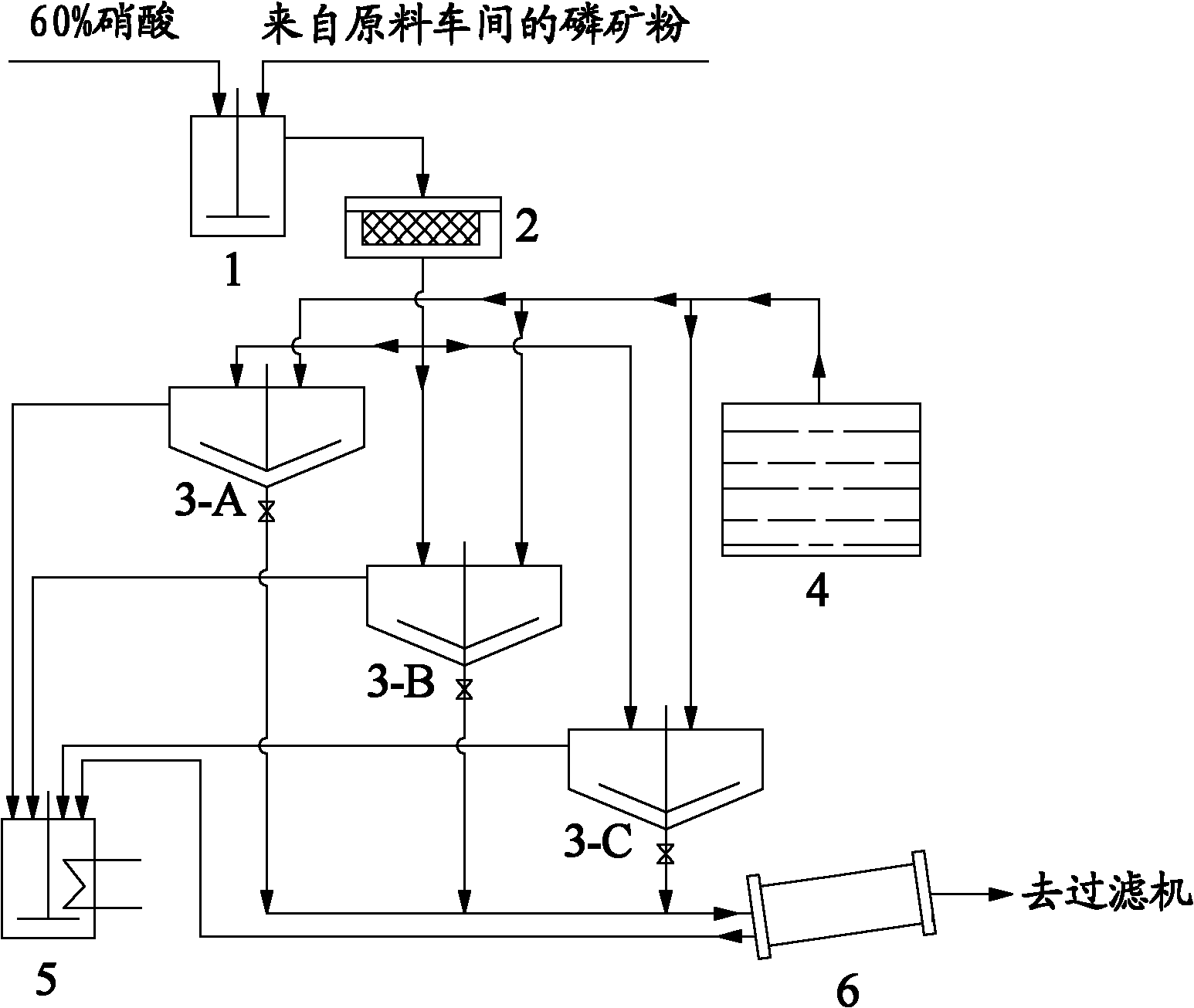

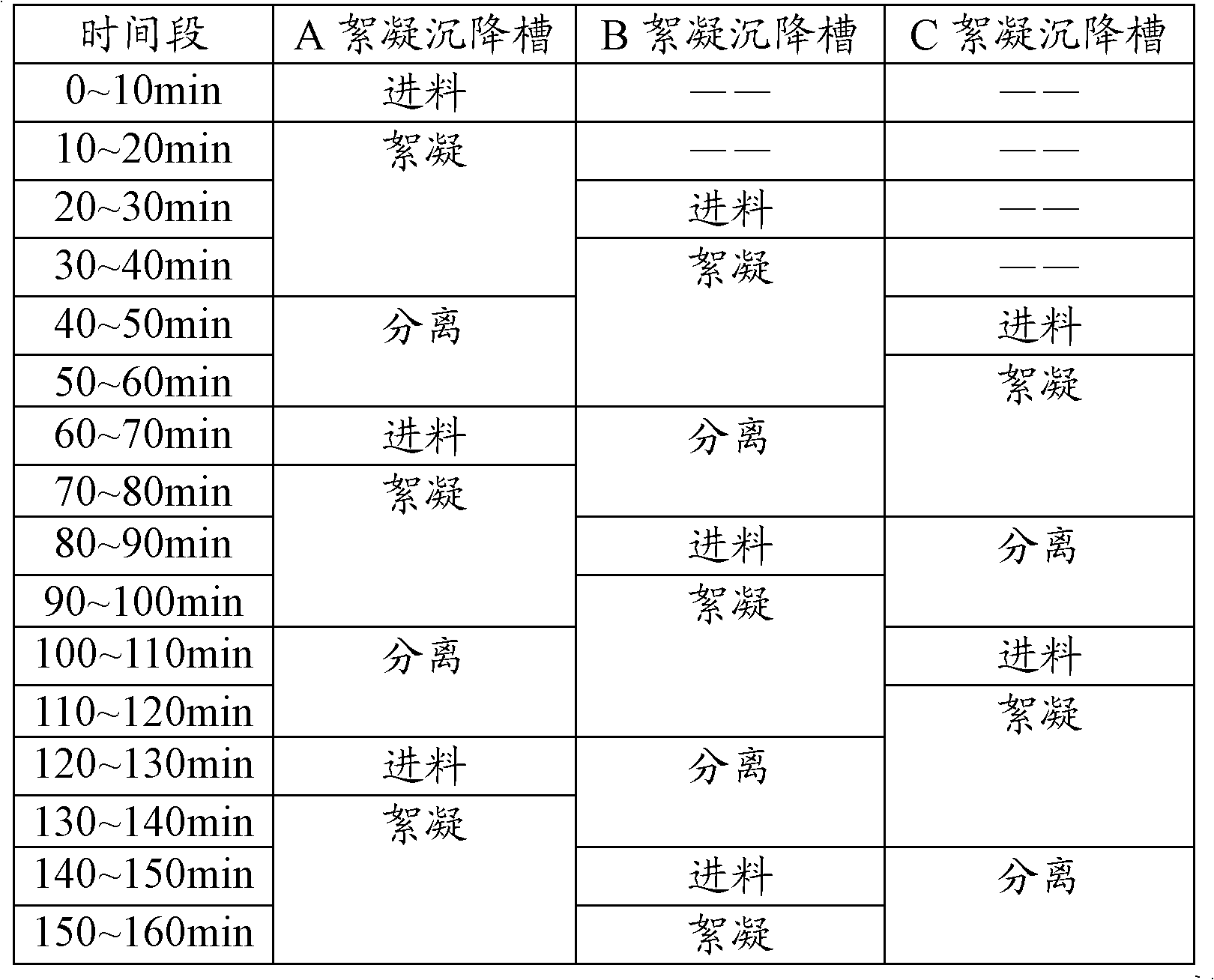

[0021] Taking the setting of three flocculation-settling tanks A, B and C as an example, the specific process flow is as follows (such as figure 1 shown):

[0022] 1) Feeding: After the phosphate rock powder from the raw material workshop and excess 60% nitric acid are fully reacted in the acidolysis tank 1, the acidolysis solution obtained by the reaction enters the flocculation-settling tank 3-A, 3-B, 3-C.

[0023] 2) Flocculation: The hydrolyzed flocculant solution in the flocculant configuration tank 4 is added to the three flocculant settling tanks in order according to the designed dosage, and at the same time, the stirring paddle in the tank is fully stirred. After stirring evenly, let it stand for half an hour .

[0024] 3) Separation: The clear liquid in tank A and the fine acid insoluble matter that has not been separated enter the crystallization feeding tank 5 through the overflow pipe with the clear liquid, and the acid insoluble matter enters the washing drum 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com