Composite membrane for promoting wound repair by simulating skin texture and preparation method thereof

A wound repair and skin structure technology, applied in the fields of medical science, absorbent pads, prostheses, etc., can solve the problems of immune rejection, insufficient donors, etc., and achieve the effect of promoting synthesis, good absorption, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

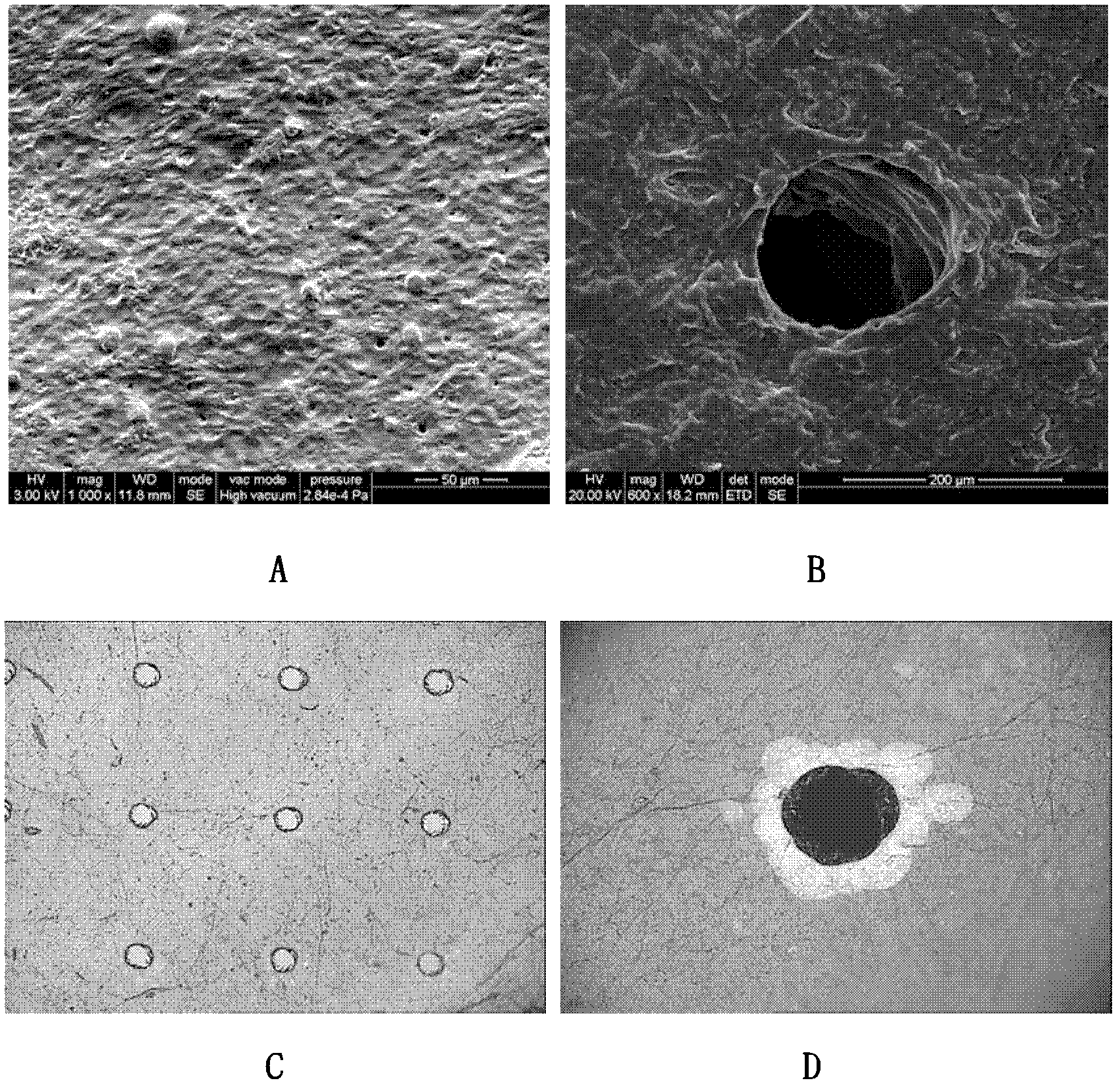

[0042] (a) Collagen (Col), chitosan (CS) and 2-methacryloxyethyl phosphorylcholine (MPC) were dissolved in hexafluoroisopropanol at a mass ratio of 65:20:15 In the solvent, the total mass volume concentration of collagen (Col), chitosan (CS) and 2-methacryloyloxyethyl phosphorylcholine (MPC) is 70mg / ml, stirred to a homogeneous solution;

[0043] (b) Pour the solution obtained in step (a) into a polytetrafluoroethylene mould. After the solvent volatilizes, the film can be removed to obtain a dense composite film, which is placed in a vacuum at -0.1MPa and a temperature of 120° Dry in a vacuum drying oven for 48 hours to promote the complete evaporation of the solvent;

[0044] (c) After the dried composite film of step (b) is placed in a desiccator and cross-linked with glutaraldehyde steam for 36 hours, the cross-linked composite film is placed in distilled water and washed for 3 days until the glutaraldehyde in the composite film is washed. The dialdehyde is completely remo...

Embodiment 2

[0048] (a) Collagen (Col), chitosan (CS) and 2-methacryloyloxyethyl phosphorylcholine (MPC) were dissolved in hexafluoroisopropanol at a mass ratio of 55:25:20 In the solvent, the total mass volume concentration of collagen (Col), chitosan (CS) and 2-methacryloyloxyethyl phosphorylcholine (MPC) is 80 mg / ml, stirred to a homogeneous solution;

[0049] (b) Pour the solution obtained in step (a) into a polytetrafluoroethylene mold. After the solvent volatilizes, the film can be removed to obtain a dense composite film, which is placed in a vacuum with a vacuum degree of -0.1MPa and a temperature of 120°. Dry in a drying oven for 48 hours to promote the complete evaporation of the solvent;

[0050] (c) After the dried composite film of step (b) is placed in a desiccator and cross-linked with glutaraldehyde steam for 48 hours, the cross-linked composite film is placed in distilled water and washed for 3 days until the glutaraldehyde in the composite film is washed. The dialdehyde ...

Embodiment 3

[0055] (a) Collagen (Col), chitosan (CS) and 2-methacryloyloxyethyl phosphorylcholine (MPC) were dissolved in hexafluoroisopropanol at a mass ratio of 45:30:25 In the solvent, the total mass volume concentration of collagen (Col), chitosan (CS) and 2-methacryloyloxyethyl phosphorylcholine (MPC) is 90 mg / ml, stirred to a homogeneous solution;

[0056] (b) Pour the solution obtained in step (a) into a polytetrafluoroethylene mould. After the solvent volatilizes, the film can be removed to obtain a dense composite film, which is placed in a vacuum at -0.1MPa and a temperature of 120° Dry in a vacuum drying oven for 48 hours to promote the complete evaporation of the solvent;

[0057] (c) After the dried composite film of step (b) is placed in a desiccator and cross-linked with glutaraldehyde steam for 60 hours, the cross-linked composite film is washed in distilled water for 3 days until the glutaraldehyde in the composite film is washed. The dialdehyde is completely removed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com