Headbox, sheet-forming unit having a headbox and method for operating a sheet-forming unit

A headbox and turbulent flow technology, applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problems of unsuitable single fiber suspension residence time, compression, etc., to optimize the distribution of fibers and fillers or Effect of shaped, compact construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

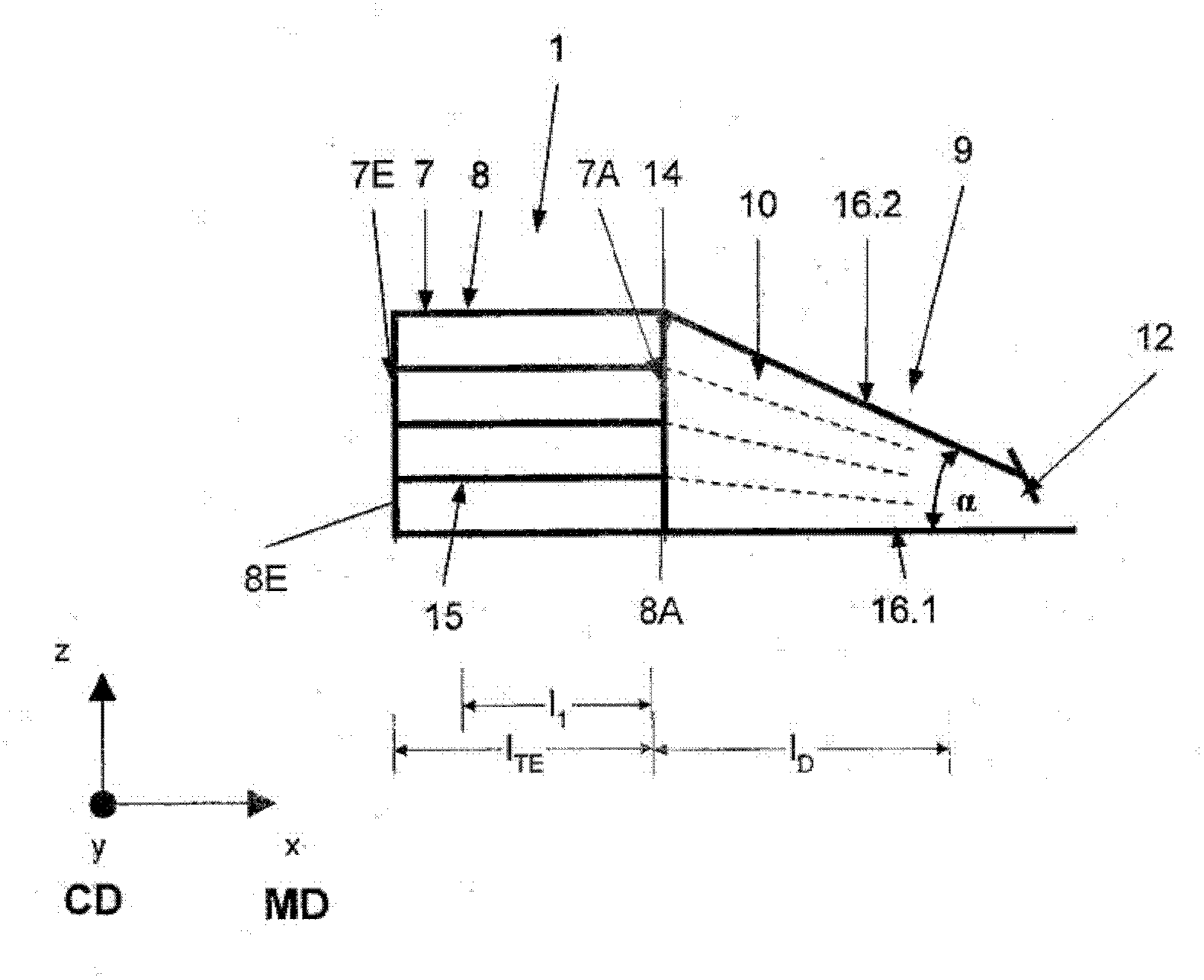

Embodiment Construction

[0045] figure 2 In the simplified schematic diagram, the influence of the substance concentration SK in the fiber suspension FS on the composition is explained based on the graph. For this reason, the floc structure FL in the free bundle is plotted against the substance concentration SK in the form of the size of the formed floc. This shows the relationship between the high substance concentration SK and the uneven and coarse composition in the arrangement of the fibers and the filler due to the increased fiber flocculation, that is, in the case of the conventional known headbox Next, there is a tendency for larger flocs in the fiber suspension in the free bundle F in the outlet gap of the headbox. It is also obvious that in a fiber suspension with a lower substance concentration, here is 1.2% substance concentration characteristic value SK X Below, the floc formation is low, that is, only smaller flocs are observed in the free jet F at the exit gap of the headbox. figure 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com