Excavator comprehensive performance testing system

A technology for excavators and hydraulic excavators, which is applied in the field of excavator comprehensive performance test systems, can solve problems such as the lack of comprehensive performance test systems, and achieve the effect of avoiding wiring difficulties and enhancing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

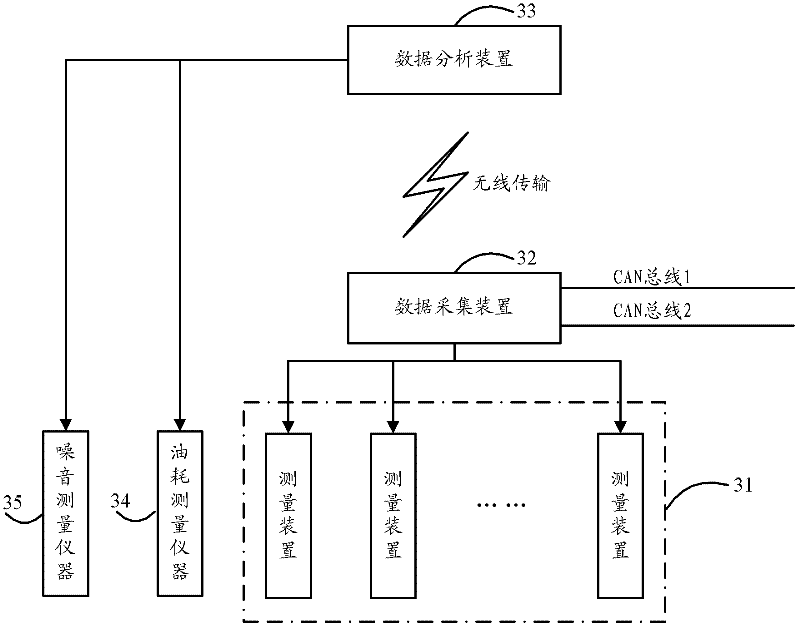

[0058] The present invention provides an embodiment of an excavator comprehensive performance testing system, which is suitable for comprehensive performance testing of components of hydraulic excavators and hybrid excavators (hereinafter collectively referred to as excavators), such as image 3 As shown, the system includes the following parts: a measuring device 31 , a data acquisition device 32 , a data analysis device 33 , a fuel consumption measuring instrument 34 , and a noise measuring instrument 35 . Among them, the specific structure and function of each part are as follows:

[0059] The measuring device 31 is a plurality of test sensors connected to each test object of the excavator, and each measuring device 31 is connected with the corresponding test object on the excavator (the components that need to be tested for performance in the excavator), and is used for connecting The test object carries out the measurement of relevant data, and obtains the test data.

[...

Embodiment 2

[0109] The embodiment of the present invention also provides another excavator comprehensive performance testing system. Compared with the previous embodiment, the data acquisition device and the data analysis device in the present invention have more abundant functions.

[0110] Such as Figure 7 As shown, compared with the data acquisition device 32 of the previous embodiment, the data acquisition device 32 in this embodiment also includes the following parts:

[0111] The data storage module 324 is configured to save the collected data sent to the data analysis device 33 by the RT controller 321_A.

[0112] The debugging module 325 is used to monitor the status of each functional module in the entire chassis of the data acquisition device 32 during operation, and send it to the data analysis device 33 .

[0113] Such as Figure 8 As shown, compared with the data analysis device 33 of the previous embodiment, the data analysis device 33 in this embodiment also includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com