A hydraulic system load intelligent control system

A technology of intelligent control system and hydraulic system, applied in fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as complex circuits, increased failure probability density, increased energy consumption, etc., and achieve simplification The effect of controlling the line, reducing the probability density and cost of failure, and avoiding the difficulty of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

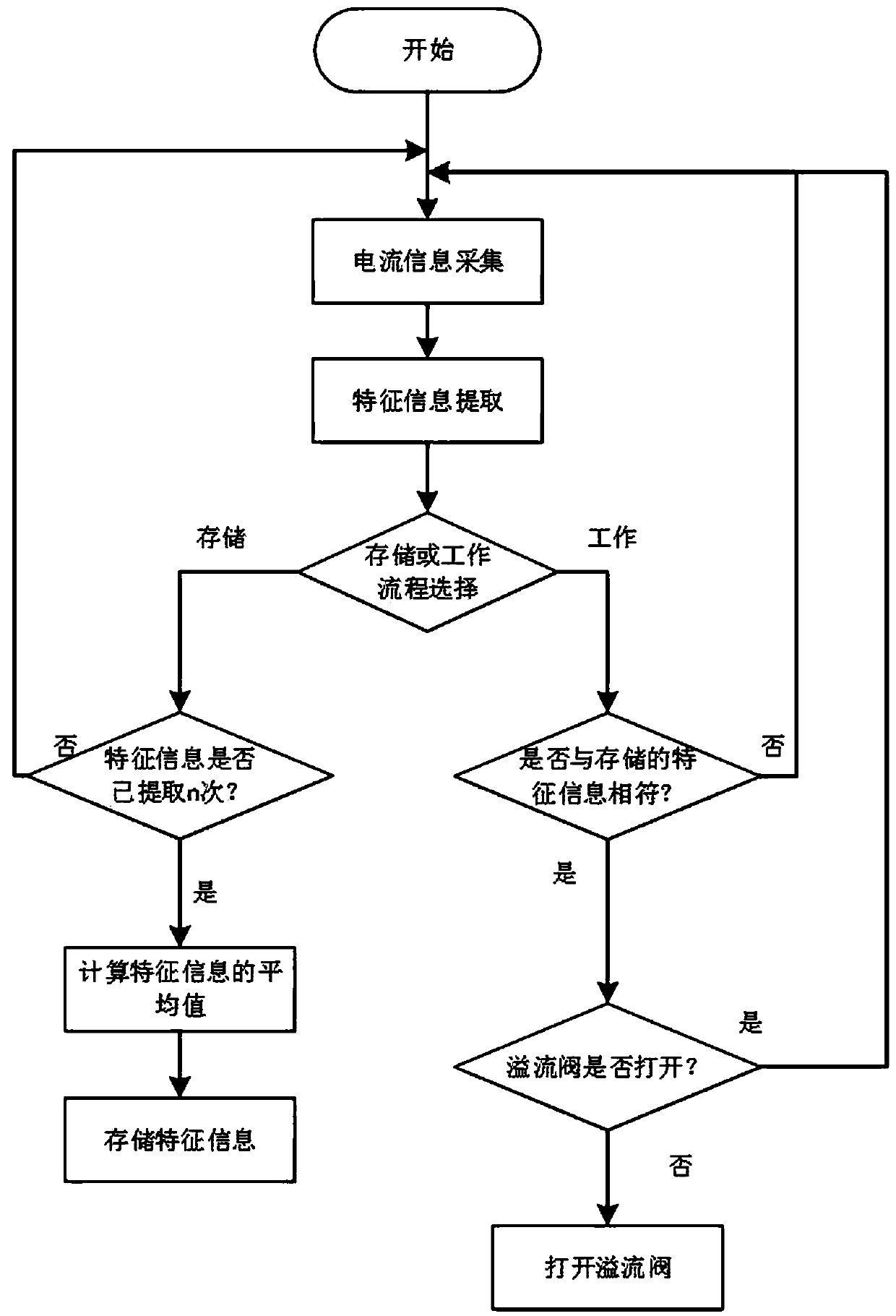

[0014] Attached below figure 1 The present invention will be further described.

[0015] An intelligent load control system for a hydraulic system, in which each actuator valve in the hydraulic system is connected to a power supply through a current information acquisition device, and the control steps are as follows: a) The coil drive current value of each actuator valve when the current information acquisition device is working For detection, the number of acquisitions is N times, and N is a natural number greater than or equal to 2. The current value collected by each valve N times is converted into a digital signal by the A / D converter, and then the processor calculates the average current value of each valve , and will Stored in the memory; b) Start the hydraulic system; c) The current information acquisition device collects the coil drive current value of each actuator valve when it is working , the processor converts the current current value and the average val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com