Vibration test system of locomotive cooling tower

A technology for vibration testing and cooling towers, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc. It can solve problems such as difficult directions, difficult to unify test points, low precision and reliability, and achieve high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

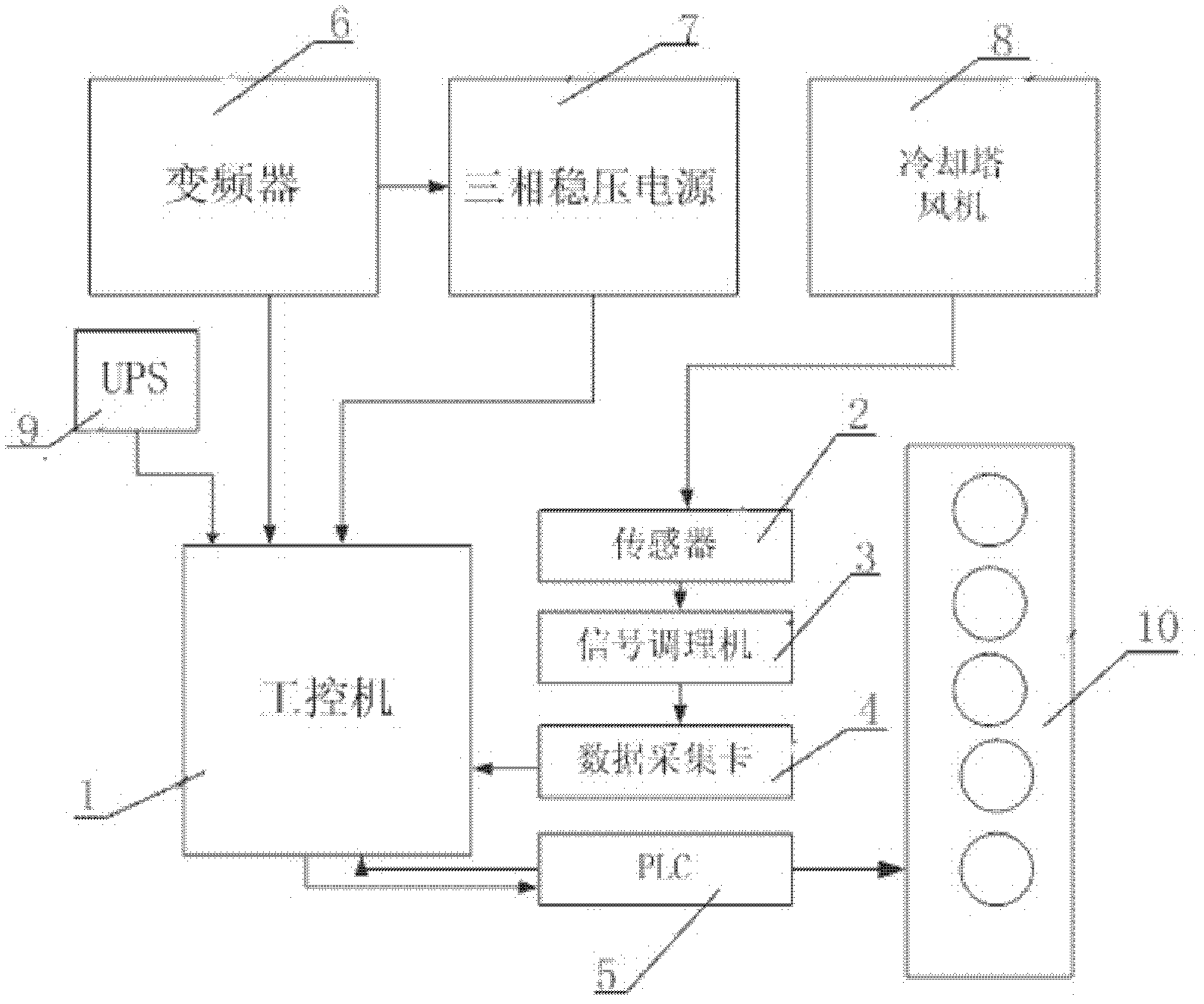

[0019] see figure 1 and figure 2 , a cooling tower vibration test system for locomotives, including a test bench and a power cabinet, characterized in that the test bench includes an industrial computer module 1 displayed in intuitive digital form and waveform form, and a piezoelectric type for collecting cooling tower fan 8 signals. Sensor 2, signal conditioner module 3, data acquisition card 4, lower computer module 5 and indicator light 10;

[0020] The power cabinet includes a power main circuit, a frequency converter module 6 and a three-phase stabilized power supply module 7,

[0021] One end of the frequency converter module 6 is connected to the industrial computer module 1, and the other end is connected to the three-phase regulated power supply module 7, and the output end of the three-phase regulated power supply module 7 is connected to the industrial computer module 1;

[0022] The output end of the piezoelectric sensor 2 for collecting the cooling tower fan 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com