High-speed rail measurement control point CPIII marking post detector

A measurement control and marker rod technology, which is applied to measurement devices, instruments, etc., can solve problems such as the lack of effective detection methods for assembly accuracy and interchange accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, it should be emphasized that the following embodiments are only exemplary and not intended to limit the scope and application of the present invention.

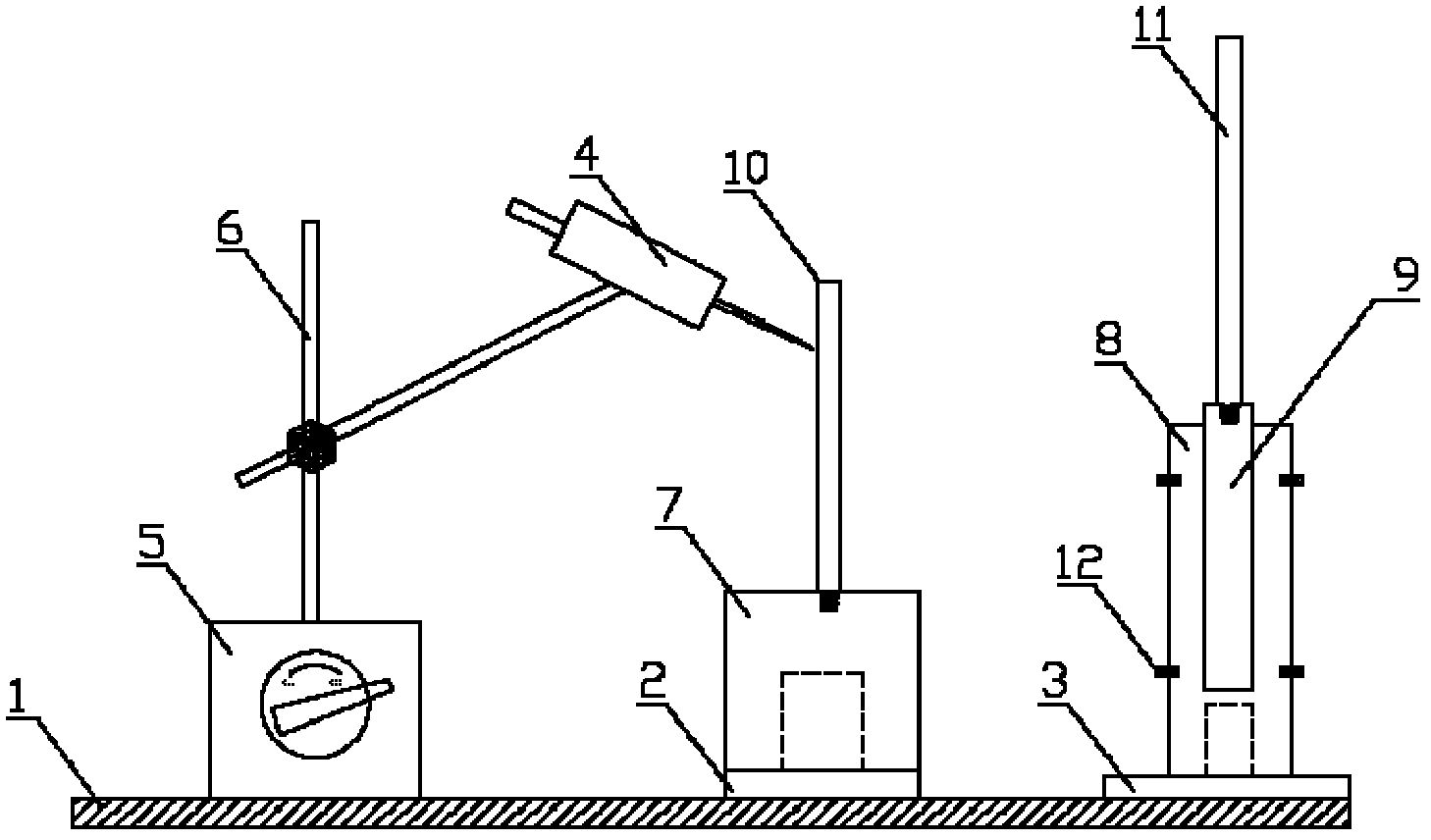

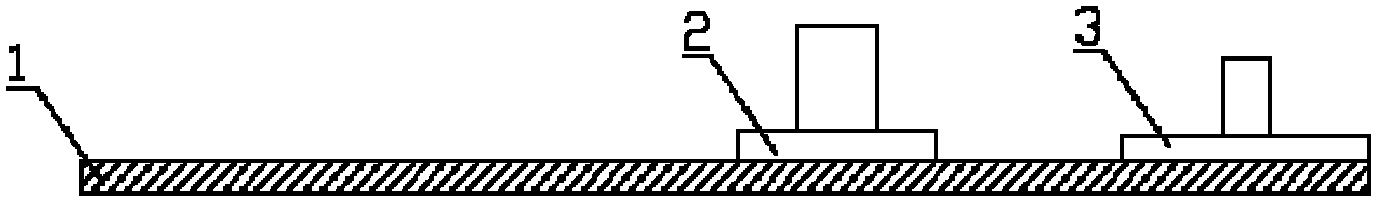

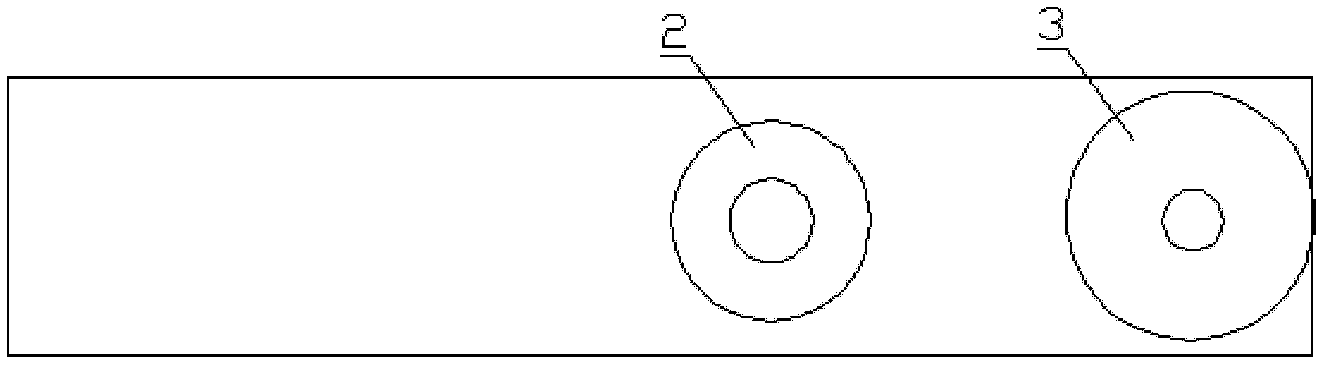

[0022] Figure 1-Figure 8 As shown, the specific implementation method of the present invention is: the base 1 is a long steel plate integral structure, and there are two rotatable cylindrical detection platforms, one high and one short, distributed along the length direction. The bases 2 and 3 of the testing platform are respectively fixed on the base 1, and the two testing platforms are equipped with hollow cylindrical sleeves 7 and 8 which can fit with the bases, and the sleeves can rotate around the outer edge of the base. A threaded opening is left on the top of the cylindrical sleeve 7 of the first testing platform, and the marking pin 10 can be bolted on the testing platform. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com