Control structure and control method for switching electric control to hydraulic control for electric control master pump of excavator

A control method and control structure technology, which is applied to earth movers/shovels, construction, etc., can solve problems such as the inability to move excavators, the inability to construct the whole machine, and the inability to switch hydraulic control, so as to shorten the time wasted waiting for maintenance, The effect of avoiding the customer's construction period and reducing the scope of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

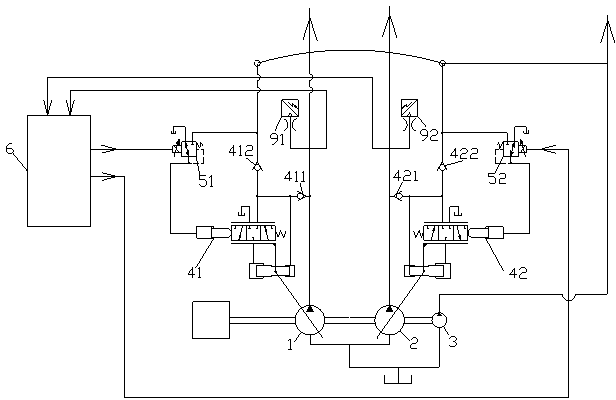

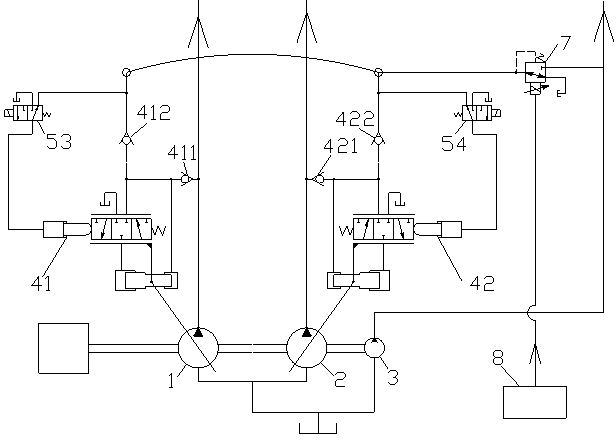

[0037] The present invention is a control structure in which the electronically controlled main pump of an excavator is switched to hydraulically controlled, which includes a main pump electronically controlled structure and a main pump hydraulically controlled structure, and the main pump electronically controlled structure and the main pump hydraulically controlled structure are controlled by replacing switch.

[0038] Such as figure 1 As shown, the electronically controlled main pump structure includes a front pump 1, a rear pump 2, a pilot gear pump 3, a first regulator 41, a second regulator 42, a first electromagnetic proportional valve 51, a second electromagnetic proportional valve 52 and a controller 6. The first regulator 41 includes a hydraulic control mechanism, the oil inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com