DSA (Dimensionally Stable Anode) electrode and manufacturing method thereof

A manufacturing method and electrode technology, applied in the field of electrolysis, can solve the problems of poor bonding between the coating and the substrate, easy peeling and passivation, and high cost, and achieve the effects of reduced thickness, difficult peeling, and moderate grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

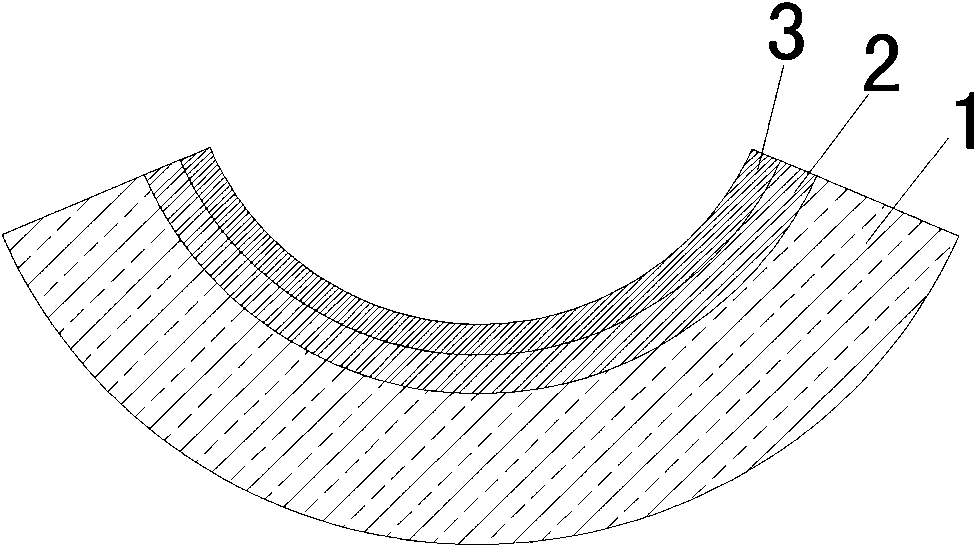

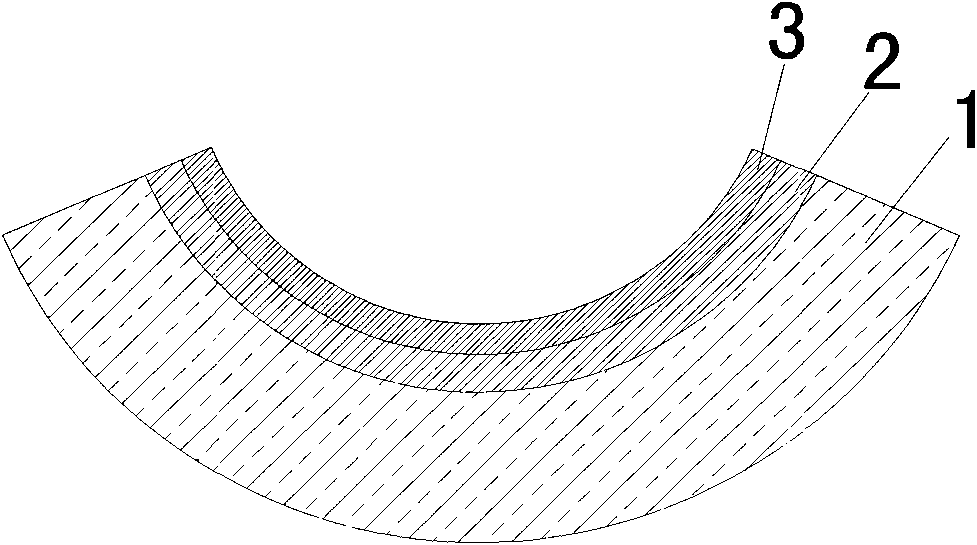

[0031] see figure 1 , the DSA electrode of the present invention is composed of a metal substrate 1 , an intermediate protective layer 2 and a surface active coating 3 . The metal matrix is selected from one of metal Ti, metal Ta or a metal composite material covered with Ta on the surface; the intermediate protective layer is composed of a multi-component compound composed of platinum group metal oxides and other metal oxides; the surface active coating is composed of IrO 2 ·Ta 2 o 5 constitute.

[0032] The preferred composition of the DSA electrode of the present invention is to use metal Ti as the matrix, and use Ta 2 o 5 ·TiO 2 As an intermediate protective layer, IrO 2 ·Ta 2 o 5 As a surface active coating.

[0033] The manufacturing method of the DSA electrode of the present invention, taking the preparation of the DSA electrode for the electrolytic copper foil raw foil machine as an example, the steps are as follows:

[0034] A titanium plate with a length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com