Method for extracting rare earth from kaolin product containing ion-type rare earth

A technology of ionic rare earth and kaolin, applied in the direction of improving process efficiency, can solve the problems of poor permeability, strong viscosity, recovery of ionic rare earth, etc., so as to solve the problem of environmental pollution, solve the problem of poor permeability and effectively utilize resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

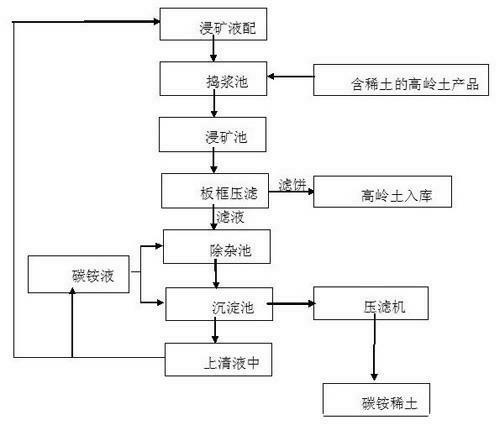

Image

Examples

Embodiment Construction

[0013] Pretreatment: After beneficiation of kaolin raw ore, it is made into kaolin products with ionic rare earth grade reaching the lowest mining industrial grade.

[0014] Pounding: The method of pounding is used to overcome the technical problem of poor permeability of kaolin. Mix the kaolin product containing ionic rare earth with 20g / L ammonium sulfate solution at a mass ratio of 1:3-4, mash and leaching the ore for 4 to 8 hours to form a pulp with a concentration of 20%-25% by mass;

[0015] Ore leaching: pump the ore pulp into the leaching pool, and stir continuously in the leaching pool to fully react the ionic rare earth in the kaolin product with ammonium sulfate;

[0016] Plate and frame filter press: the method of pounding is used to overcome the technical problem that kaolin is difficult to separate solid and liquid. Filter the ore pulp in the leaching pool with a plate-and-frame filter press, the filter cloth mesh of the plate and frame is 850 mesh, the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com