Preparation method of white carbon black modified styrene-butadiene rubber facing green tires and product thereof

A technology of styrene-butadiene rubber and silica, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems that the physical properties of vulcanized rubber cannot reach the best state, cannot force silica to disperse, and achieve mechanical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

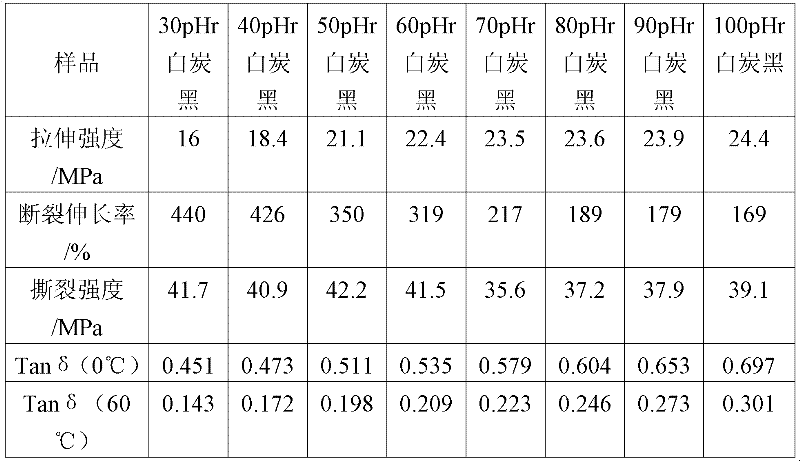

Embodiment 1

[0021] 1. First prepare the styrene-butadiene rubber liquid slurry containing white carbon black:

[0022] Mix silica and water at a mass percentage of 5:95, and treat for 5 hours in a high-shear dispersing emulsifier at a rotational speed of 13,000 rpm to obtain a stable silica-water suspension, and the dispersion state of silica in water is good. Take 600g of silica-water suspension and 3g of KH590, and organically modify the silica-water suspension by adding KH550 dropwise in a water bath environment at 70°C. The water bath time is 3h, and fully stirred to ensure its modification effect . Aqueous ammonia was added to the suspension to bring the pH of the suspension to 9. Get the styrene-butadiene latex 483.09g that solid content is 20.7%, this suspension is joined in the styrene-butadiene latex, fully stirs and it is evenly mixed, and the obtained white carbon black content is 30pHr (being white carbon black and styrene-butadiene latex dry glue The mass ratio is 30%) of t...

Embodiment 2

[0026] 1. First prepare the styrene-butadiene rubber liquid slurry containing white carbon black:

[0027] Mix silica and water at a mass percentage of 20:80, and treat for 2 hours in a high-shear dispersing emulsifier at a rotational speed of 22,000 rpm to obtain a stable silica-water suspension, and the dispersion state of silica in water is good. Take 200g of silica-water suspension and 2.4g of KH590, organically modify the silica-water suspension by adding KH570 dropwise in a water bath environment at 80°C, the water bath time is 2h, and stir fully to ensure its modification Effect. Aqueous ammonia was added to the suspension to bring the pH of the suspension to 12. Get the styrene-butadiene latex 483.09g that solid content is 20.7%, this suspension is joined in the styrene-butadiene latex, fully stirs and it is evenly mixed, and the obtained white carbon black content is 40pHr (being white carbon black and styrene-butadiene latex dry glue The mass ratio is the styrene-b...

Embodiment 3

[0031] 1. First prepare the styrene-butadiene rubber liquid slurry containing white carbon black:

[0032] Mix silica and water at a mass percentage of 10:90, and treat for 3 hours in a high-shear dispersing emulsifier at a rotational speed of 19,000 rpm to obtain a stable silica-water suspension, and the dispersion state of silica in water is good. Take 500g of silica-water suspension and 5g of KH590, and organically modify the silica-water suspension by adding KH590 dropwise in a water bath environment at 75°C. The water bath time is 2.5h, and stir fully to ensure its modification Effect. Aqueous ammonia was added to the suspension to bring the pH of the suspension to 10. Get the styrene-butadiene latex 483.09g that solid content is 20.7%, this suspension is joined in the styrene-butadiene latex, fully stirs and it is uniformly mixed, and the obtained white carbon black content is 50pHr (being that white carbon black and styrene-butadiene latex dry glue The mass ratio is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com