Thermo-sensitive transparent biocompatible material

A biocompatible and temperature-sensitive technology, applied in the field of materials science, can solve the problems of extensive use, high cost and high cost of NIPAm, and achieve the effect of simple and easy process and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

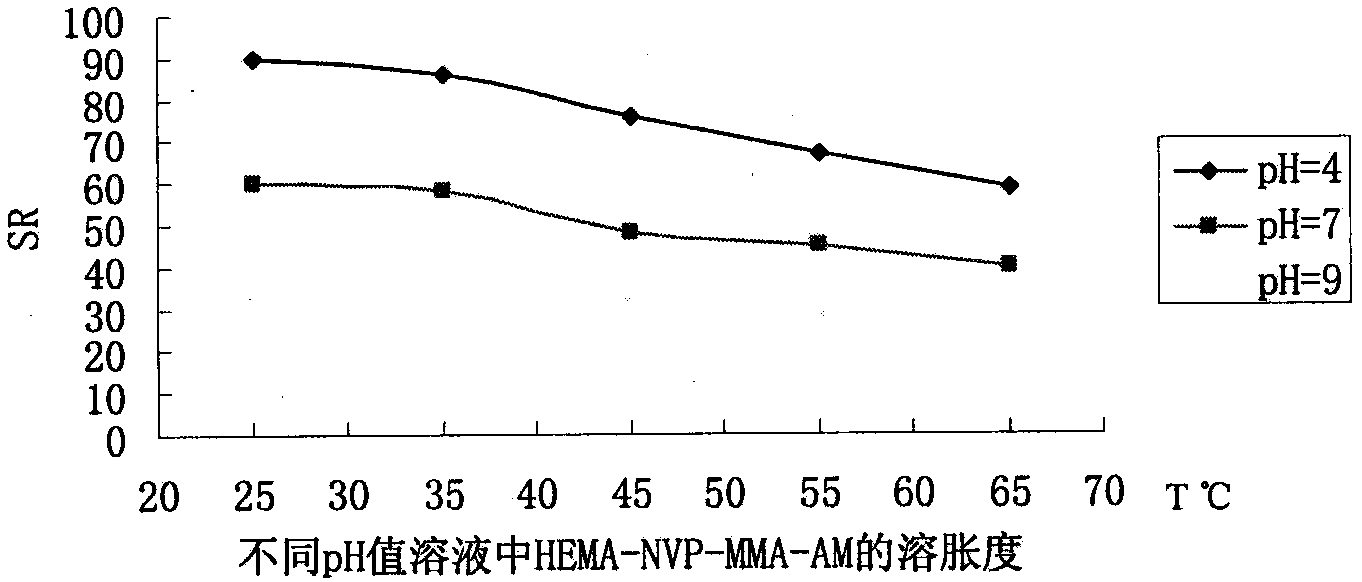

Image

Examples

Embodiment 1

[0019] According to the ratio of Example 1 in Table 1, accurately measure HEMA, NVP, MMA, AM, add 0.1% initiator N, N,-methylenebisacrylamide, azobisisobutyronitrile AIBN and place it in a 50ml beaker In, seal the mouth of the beaker. Ultrasonic vibration is then used to dissolve the contents of the beaker so that the components are completely and uniformly mixed.

[0020] Filter the prepared mixed solution under dust-free operation, absorb the obtained filtrate with a dropper, drop it into the treated mold, seal it and place it in a constant temperature water bath at 60~70°C for 16 hours or 28 hours, after the reaction is complete Soak in constantly changing distilled water to remove unreacted monomers and release the mold to obtain the product.

[0021] Table 1 ratio table

[0022]

[0023] Sample serial number 2-Hydroxyethyl methacrylate (HEMA) N-vinylpyrrolidone (NVP) Methyl methacrylate (MMA) Acrylamide (AM) Example 1 66% 16% 8% 10% ...

Embodiment 2

[0025] According to the ratio of Example 2 in Table 1, accurately measure HEMA, NVP, MMA, AM, add 0.1% initiator N, N,-methylenebisacrylamide, azobisisobutyronitrile AIBN and place it in a 50ml beaker In, seal the mouth of the beaker. The following operations are the same as in Example 1.

Embodiment 3

[0027] According to the ratio of Example 3 in Table 1, accurately measure HEMA, NVP, MMA, AM, add 0.1% initiator N, N,-methylenebisacrylamide, azobisisobutyronitrile AIBN and place it in a 50ml beaker In, seal the mouth of the beaker. The following operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com