Flexible tobacco shred storage and distribution method

A flexible and shredded tobacco technology, which is applied in the field of cigarette shredding, can solve the problems of inability to meet group processing, refined processing and flexible processing, difficult to meet the needs of flexible production organization, and disadvantageous to small batch product shredding production and processing, etc. Achieving the effect of facilitating the balance of absorption and moisture, realizing flexible functions, and improving space utilization and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

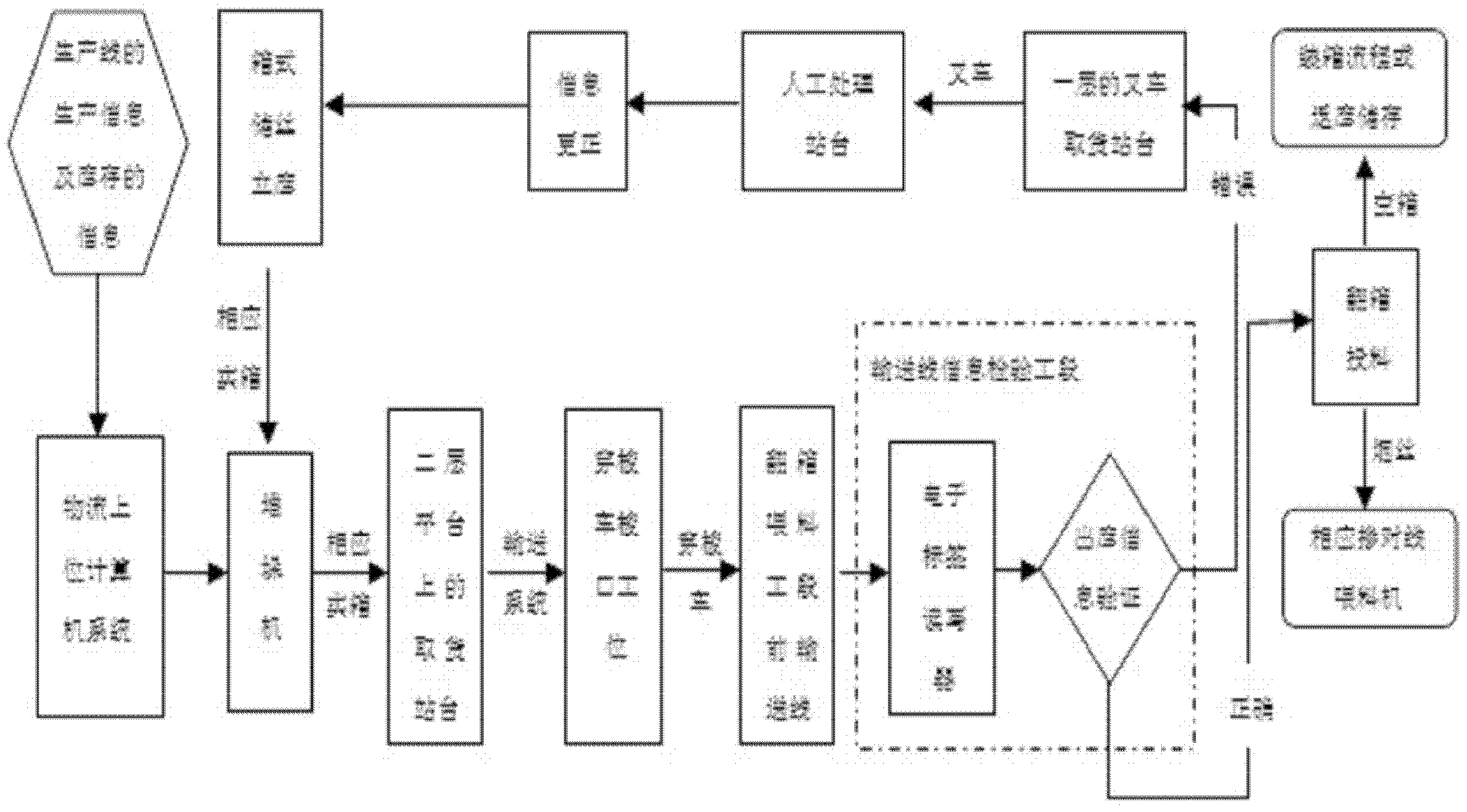

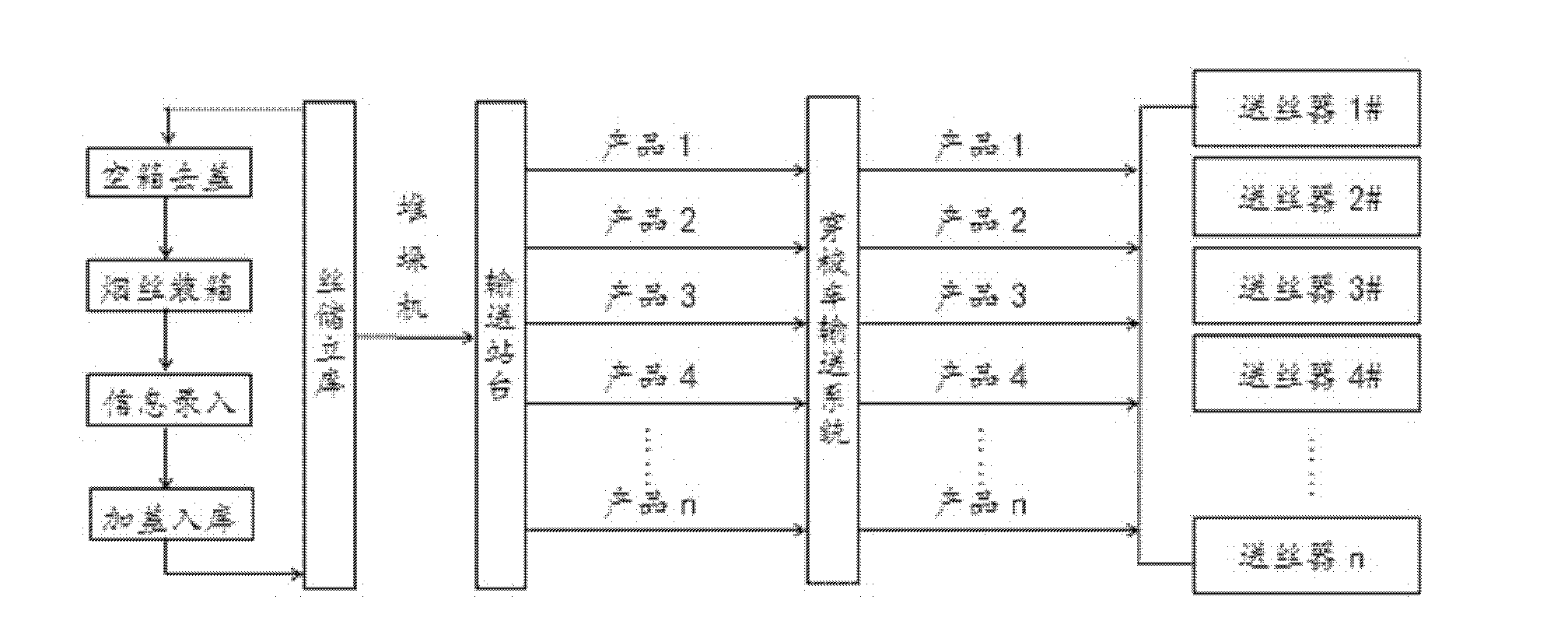

[0028] Such as figure 1 As shown in the figure, in the process flow of the flexible shredded tobacco storage and distribution logistics system, the finished shredded tobacco of each brand after flavoring is packed in cigarette boxes, and the information is entered, and stored in the shredded shredded warehouse. According to the production dispatching wire supply demand of the wrapping workshop, flexibly arrange and configure the corresponding wire feeders of each brand, and issue the output quantity instruction of each brand of cigarette boxes, and a sufficient number of track-type shuttle vehicles will realize the full box and empty boxes according to the assigned tasks. The transport of boxes between the wire storage warehouse and the wire feeding station.

Embodiment 2

[0030] The Yunyan brand produces more than 20 grades of products in Kunming Cigarette Factory, and the market size of each specification varies greatly. Therefore, higher requirements are put forward for the flexible production level of silk production. The flexible and maneuverable requirements of tobacco are very high, and the flexible shredded tobacco storage and distribution process mode of the present invention perfectly solves the difficult problem in this respect.

[0031] The new silk production line of Kunming Cigarette Factory is composed of one 3000Kg / h silk production line A and three 5000Kg / h silk production lines B, C and D. Carrying out full-recipe processing mode for silk production, and also realizing multi-module group processing mode production, this new flexible cut tobacco storage and distribution process of the present invention can meet the requirements of flexible process layout for silk production and meet the requirements of modern tobacco enterprises....

Embodiment 3

[0034] Formula 1 of a certain leaf group is processed by Line A of Kunming Tobacco Production Line, and the finished shredded tobacco is stored at 200kg / box in the vertical warehouse for 24 hours. Enter the silk storage warehouse for 24 hours, and then enter the wire feeding station through the flexible shredded tobacco distribution process. After blending at a ratio of 8:2, the finished cigarette sample 2 was rolled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com