High-efficiency slim cigarette storage method for re-drying finished cigarette packets

A cigarette pack and high-efficiency technology, applied in the field of high-efficiency cool smoke storage technology, can solve the problems of high labor intensity of workers, occupy a large warehouse space, and unfavorable storage of cigarette packs, etc., to improve the efficiency of cool smoke, save investment, and facilitate the whole process of tracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but not limited to the embodiments.

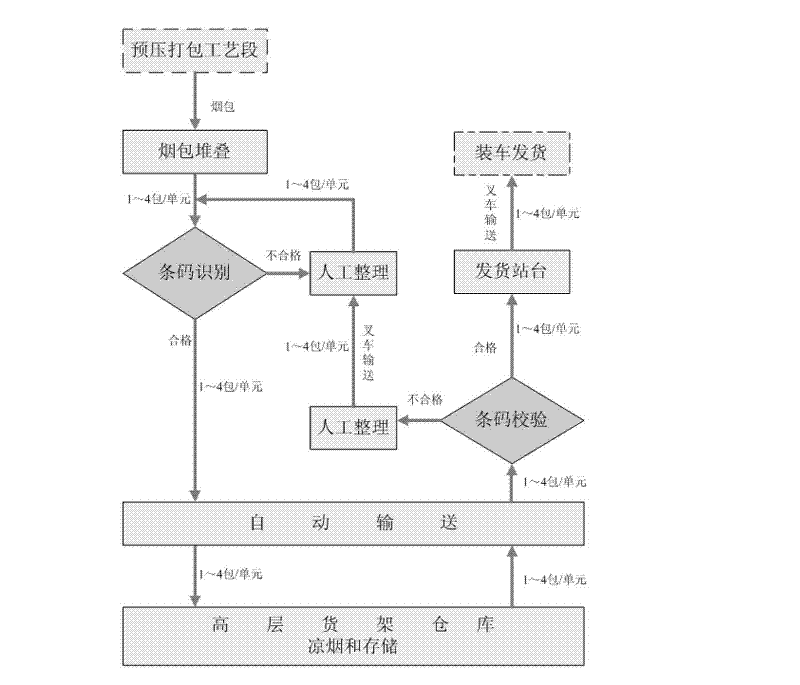

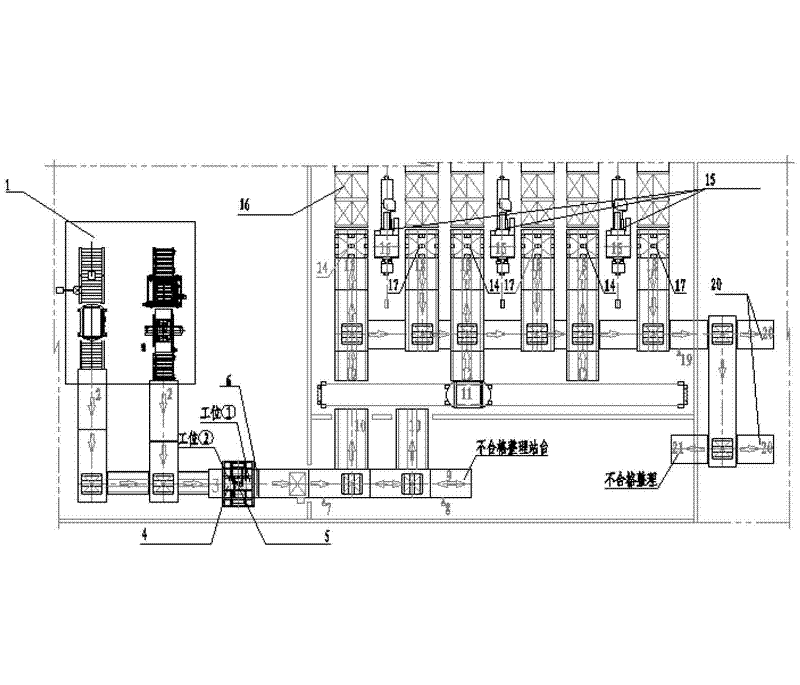

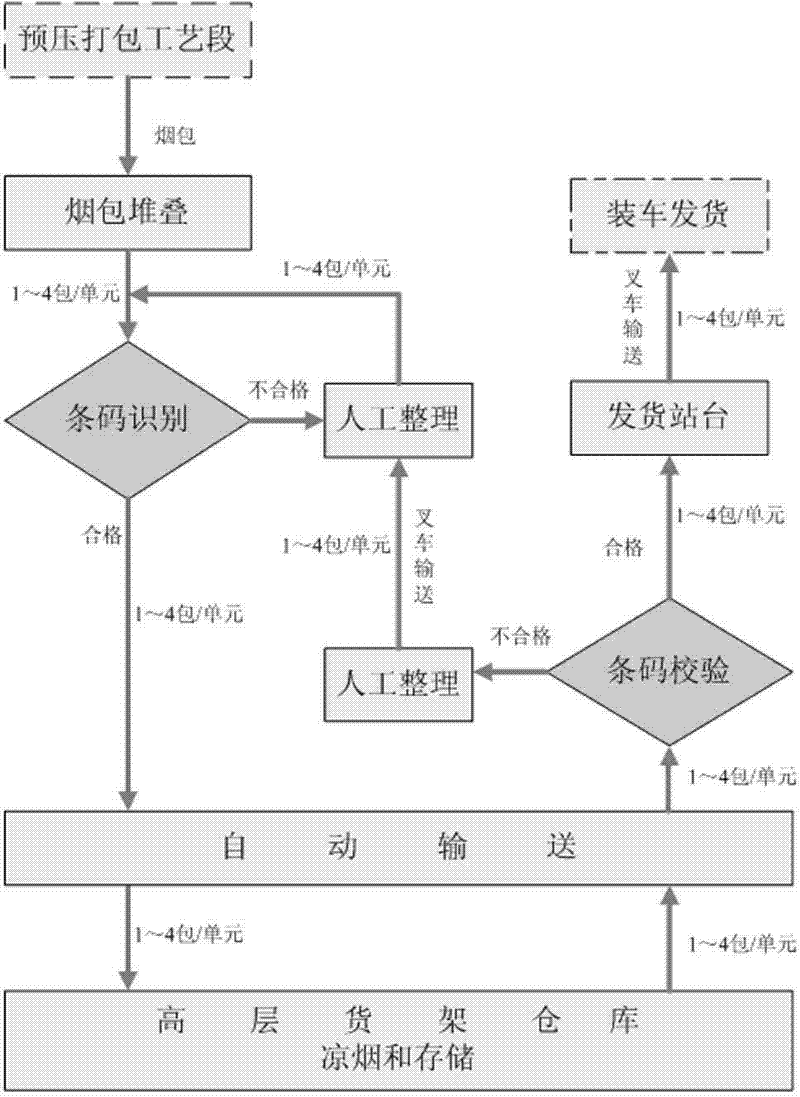

[0020] Such as figure 1 and figure 2 As shown, the automatic warehousing steps of the present invention are as follows: the pre-pressed and packed 1 bundled cigarette bales are sent to the conveying device 2, and automatically transported to the cigarette bale stacking station 4. According to the storage capacity and delivery flow requirements of different items, through automatic Stacking equipment forms a storage and conveying unit of 1 to 4 packs / unit. This station is a grade-driven accumulative conveying device 3, which can supply power in grades to form an accumulative conveying function; when one cigarette pack is used as one storage During the conveying unit, the accumulative conveying equipment 3 is only used for pseudo-ordinary conveying, and the enveloping sub-machine 5 does not work. When two cigarette packs are used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com