Electronic control unit (ECU) mounting structure for automobile

An installation structure and automobile technology, applied in vehicle parts, transportation and packaging, circuits or fluid pipelines, etc., can solve problems affecting the service life of ECU, abnormal noise, etc., to prolong service life, avoid abnormal noise, and reduce accuracy required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

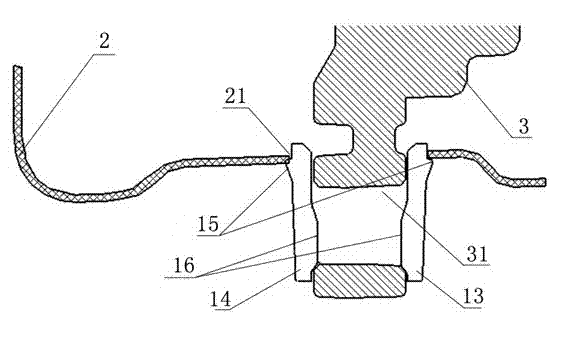

[0014] Such as figure 1 , figure 2 , image 3 The automobile ECU mounting structure shown includes ECU bracket 2 and ECU 3. The upper and lower ends of ECU 3 are respectively provided with two mounting lugs with bolt holes 31. The ECU bracket 2 is L-shaped, and its upper end is provided with two There are two bolt holes, the horizontal part of the lower end is provided with two clamping holes 21, and the ECU sheath 1 is clamped in the clamping holes 21, and the two mounting lugs on the upper end of the ECU 3 pass through the bolt holes 31 and the bolt through holes. It is fixedly connected with the ECU bracket 2 by bolts, and the two mounting lugs at the lower end are snapped into the two ECU sheaths 1 respectively. The ECU sheath 1 is composed of a front splint 13 and a rear splint 14 that are parallel to each other. On the outer side near the upper edge, there is a locking rib 15 parallel to the upper edge. On the inner side, there is a wedge-shaped locking boss 16 whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com