Bidirectional polishing and grinding machine

A technology of polishing and grinding gears, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problems of dust, low work efficiency, leaving lines, etc., to achieve labor-saving and grinding effect. Good, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

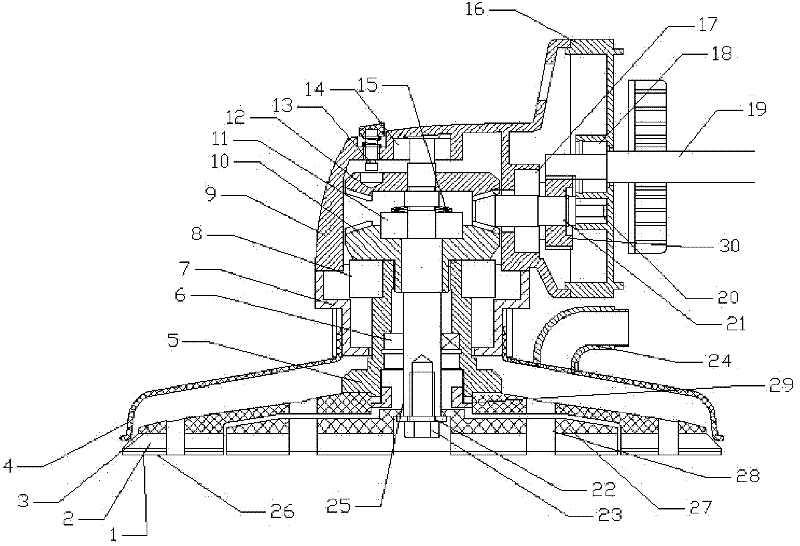

[0014] Referring to the attached picture:

[0015] 1 sticker net 2 foam sponge 3 strong wind impeller 4 main wind cover 5 flange 6 bearing 7 gearbox front cover 8 bearing 9 gearbox 10 first gear 11 bearing 12 second gear 13 self-locking pin 14 bearing 15 semicircular spring 16 gearbox 17 Bearing 18 Bearing 19 Gear Shaft 20 Bearing 21 Input Shaft 22 Gasket 23 Hexagonal Screw 24 Air Vent Joint 25 Output Shaft 26 Emery Paper 27 Small Wind Impeller 28 Air Inlet 29 Hollow Nut Press Plate 30 Gear

[0016] The two-way polishing and grinding machine of the present invention includes a gear box 9, a front cover 7, and a main wind cover 4 connected in sequence, and is characterized in that: an input shaft 21 connected to input power is provided in the gear box 9, and the There is a bevel gear at the front end of the input shaft 21; a second gear 12 is connected to the output shaft 25 perpendicular to the input shaft 21, and the first gear 10 is connected to the output shaft 25 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com