Method for rapidly repairing defects of finned tube module of waste heat boiler

A waste heat boiler and fin tube technology is applied in the field of rapidly repairing the defects of the waste heat boiler fin tube module, which can solve the problems such as the inability to repair the defects of the waste heat boiler fin tube module, and achieves good stripping effect, high speed and rapid repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] Taking the maintenance of a waste heat boiler finned tube module (defective tubes are located in the third row) to illustrate a method for quickly repairing the defects of the waste heat boiler finned tube module described in this embodiment, follow the steps below:

[0035] 1) Using the hydraulic test method, the position of the defect of the finned tube module can be roughly judged by observing the water leakage. It can be judged that the defect is located on the third or fourth row of finned tubes, and the peripheral pipes that should be cut can be determined.

[0036] 2) Using a reciprocating saw, cut off the first row of 3 pipes.

[0037] 3) Using a reciprocating saw, cut off one of the tubes in the second row. The third row of pipes has water marks, and the preliminary judgment may be that the defect may be on this finned pipe.

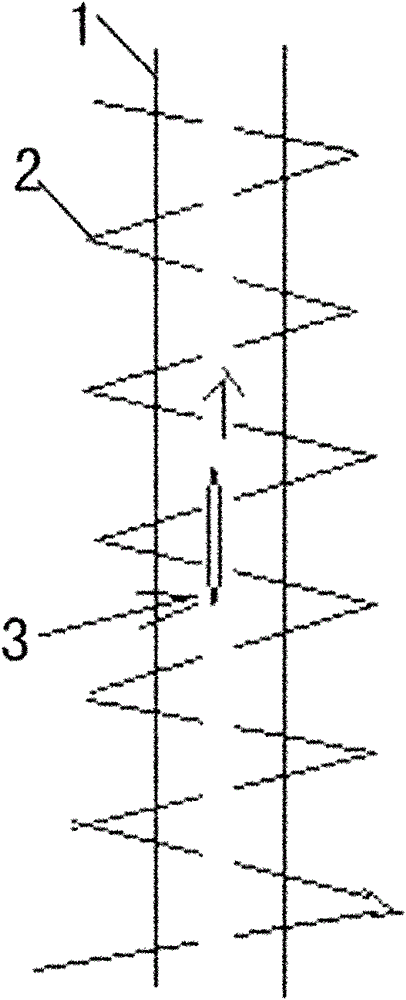

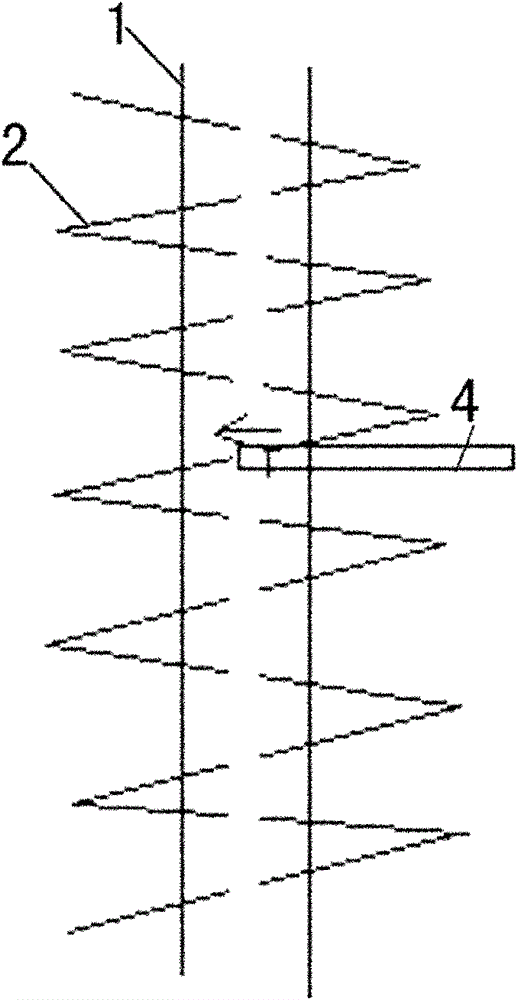

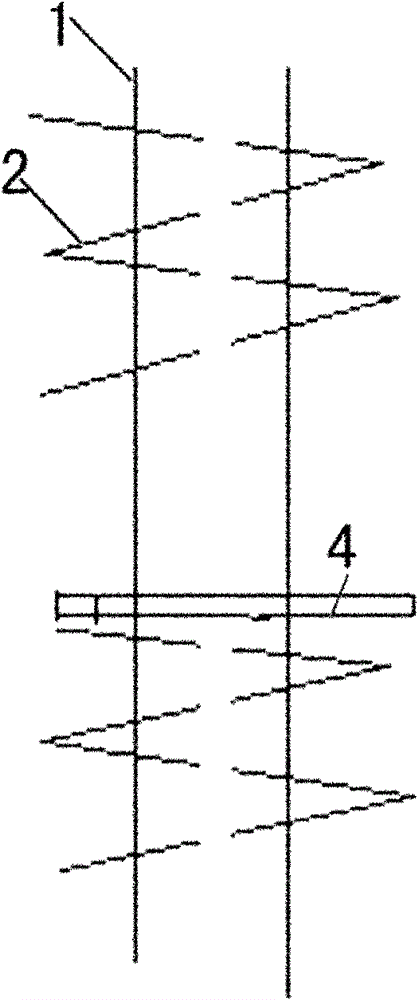

[0038] 4) Figure 1a , Figure 1b , Figure 1c First, use a grinder to cut the finned tubes in the third row of suspected defects alo...

specific Embodiment 2

[0047] Specific embodiment 2: the feature of this specific embodiment is to comprise the following steps:

[0048] 1) Preliminary judgment of the position of the defective tube of the finned tube module: the first step: through visual inspection outside the furnace and analysis of operating data, first determine the system or module to which the leak belongs, and determine the peripheral pipe that should be cut;

[0049] 2) Strip the fins of the heating tube and find out the specific position of the defective tube: First, use a cutting machine to cut the fins parallel to the heating tube radially, without cutting to the root of the fins, only need to cut the tube radially to about 4 / 5 of the fins Depth is sufficient; tap the fins axially along the diameter of the pipe with a short steel drill, pull out the fins with hand pliers after the fins are loose; after stripping the fins to form a gap of about 4cm, knock down along the pipe wall with a steel drill Hit the fins, the fins...

specific Embodiment

[0057] The characteristics of other embodiments of the present invention are: with reference to specific embodiment 2,

[0058] In step 1), when the defect location of the finned tube module cannot be judged in the first step, judge in conjunction with the second step, as follows: use the different pressure or temperature drop speeds of each system, open the manhole for observation, and judge the leak point The pipe and its approximate height; if necessary, take protective measures, including high plate purge, to accelerate the cooling of the furnace; after several observations, forcefully open the flue gas baffle to maintain the suction force on the furnace, and open the corresponding manhole door. Look inside and listen; coordinate operating personnel, and use manual intervention to operate valves during operation of the medium-pressure superheated steam system, and use auxiliary steam or high-pressure superheater to pour steam back to cooperate with leak detection;

[0059]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com