High-molecule adsorption material

A technology of polymer materials and adsorption materials, which is applied in the field of preparation of polymer adsorption materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

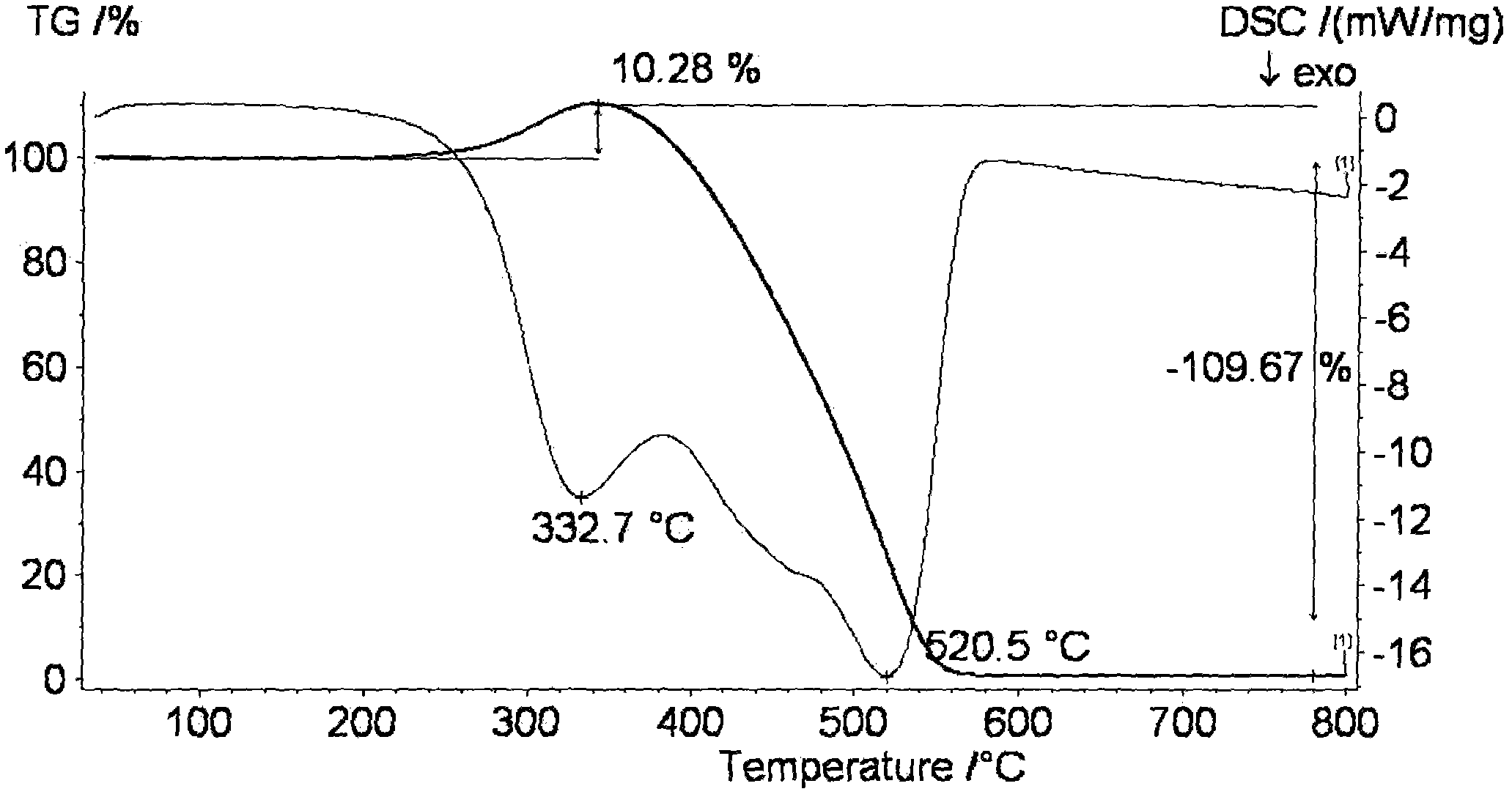

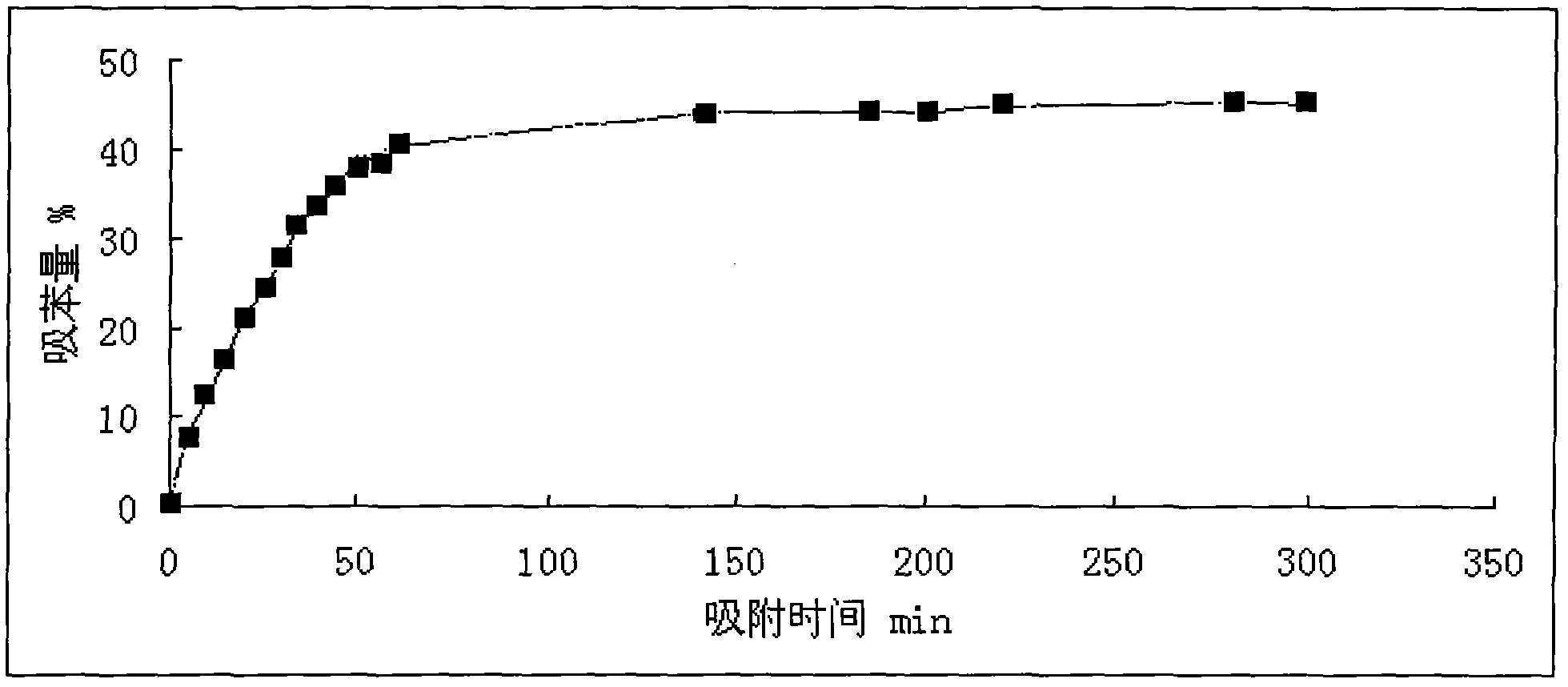

[0023] Preparation of High Specific Surface Nonflammable Polymer Adsorption Material

[0024] Add the two reactants according to the measured molar ratio (1mmol benzene and 1mmol chloromethylbenzene) into a 250ml three-necked flask, add 120ml nitrobenzene to fully swell, then add 0.2mmol of aluminum trichloride to catalyze the reaction, at 40°C The reaction was carried out under nitrogen protection for 3 hours, and then the temperature was raised to 60° C. for 12 hours. After the reaction, cool to room temperature, filter, wash with a small amount of petroleum ether, a large amount of tap water, 0.5mol / L hydrochloric acid solution, etc., and then use acetone as an extractant to reflux the product with a Soxhlet extractor, and finally dry it in vacuum at 100°C 48 hours to get the final product.

Embodiment 2

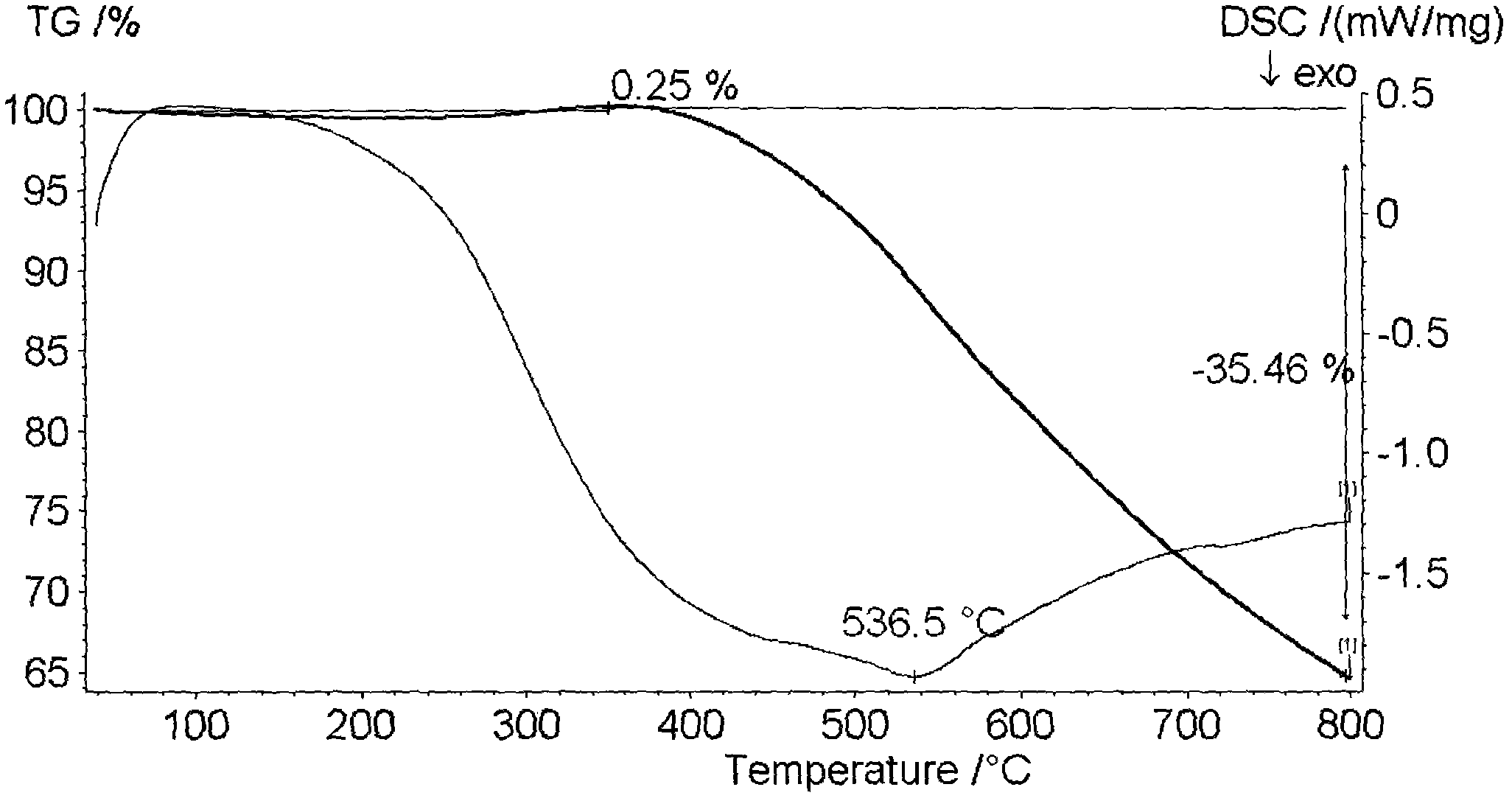

[0026] Add the two reactants according to the measured molar ratio (1mmol toluene and 5mmol dichloromethylbiphenyl) into a 500ml three-necked flask, add 200ml trichloroethane to fully swell, add 0.2mmol ferric chloride and 0.1mmol Zinc trifluoroacetate catalyzed the reaction, reacted under nitrogen protection at 60°C for 6h, and then raised the temperature to 80°C for 24h. After the reaction, cool to room temperature, filter, wash with a small amount of petroleum ether, a large amount of tap water, 0.5mol / L hydrochloric acid solution, etc., and then use acetone as the extraction agent to reflux the product with a Soxhlet extractor, and finally vacuum the product at 120 ° C. Dry for 24 hours to get the final product.

Embodiment 3

[0028]Add the two reactants into a 500ml three-necked flask according to the measured molar ratio (1mmol benzene and 8mmol chloromethylbenzene), add 120ml nitrobenzene, 100ml chlorobenzene and 30ml cyclohexane to fully swell, then add 0.2mmol trifluoro Ferric sulfonate, 0.1 mmol of boron trichloride and 0.1 mmol of tin tetrachloride catalyzed the reaction, reacted under nitrogen protection at a temperature of 5° C. for 2 hours, and then reacted at an elevated temperature of 100° C. for 48 hours. After the reaction, cool to room temperature, filter, wash with a small amount of petroleum ether, a large amount of tap water, 0.5mol / L hydrochloric acid solution, etc., and then use acetone as the extractant to reflux the product with a Soxhlet extractor, and finally vacuum the product at 160 ° C. Dry for 48 hours to get the final product.

[0029] The above description of the embodiments is for those of ordinary skill in the art to understand and apply the present invention. It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com