Grinding-after-shoveling type double-shovel peanut harvesting machine

A harvester and peanut technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve problems such as affecting the development of the peanut industry, affecting the use effect of peanut harvesting machines, and not being able to travel after harvesting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

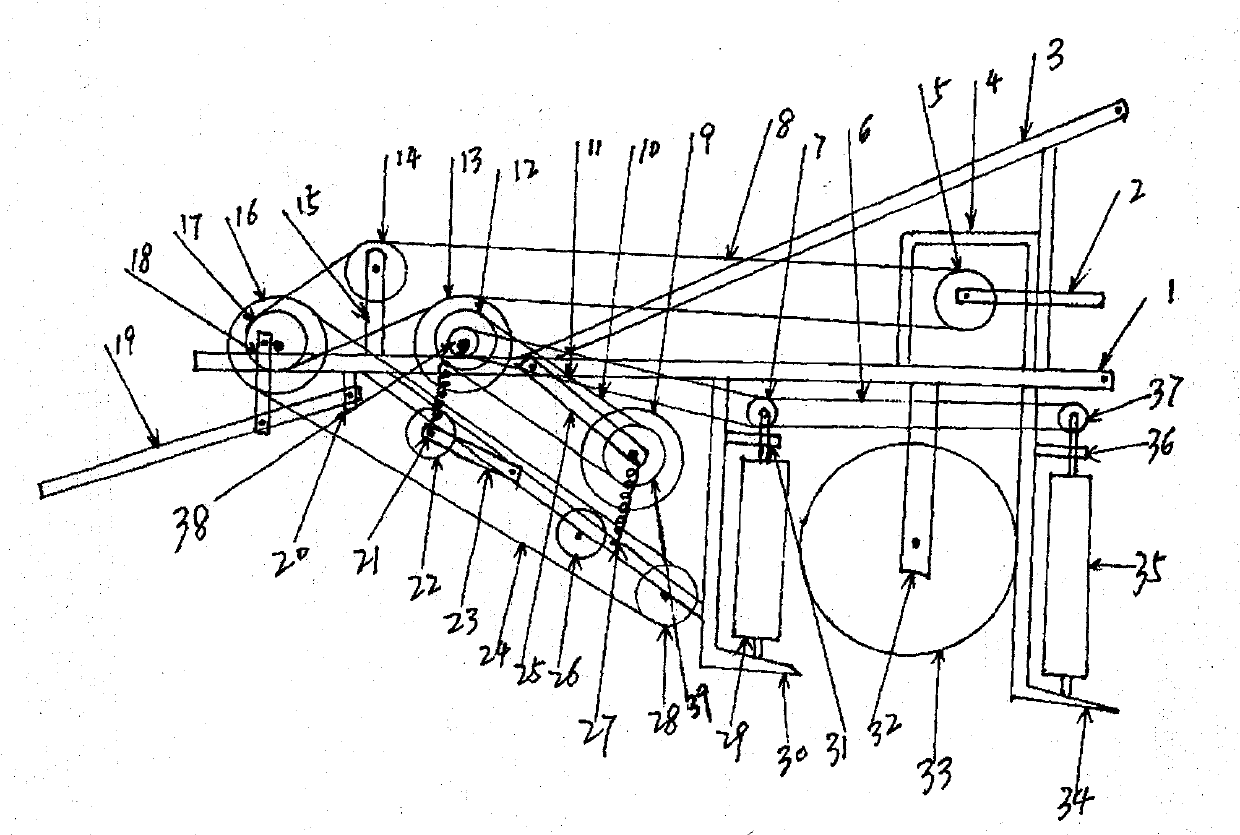

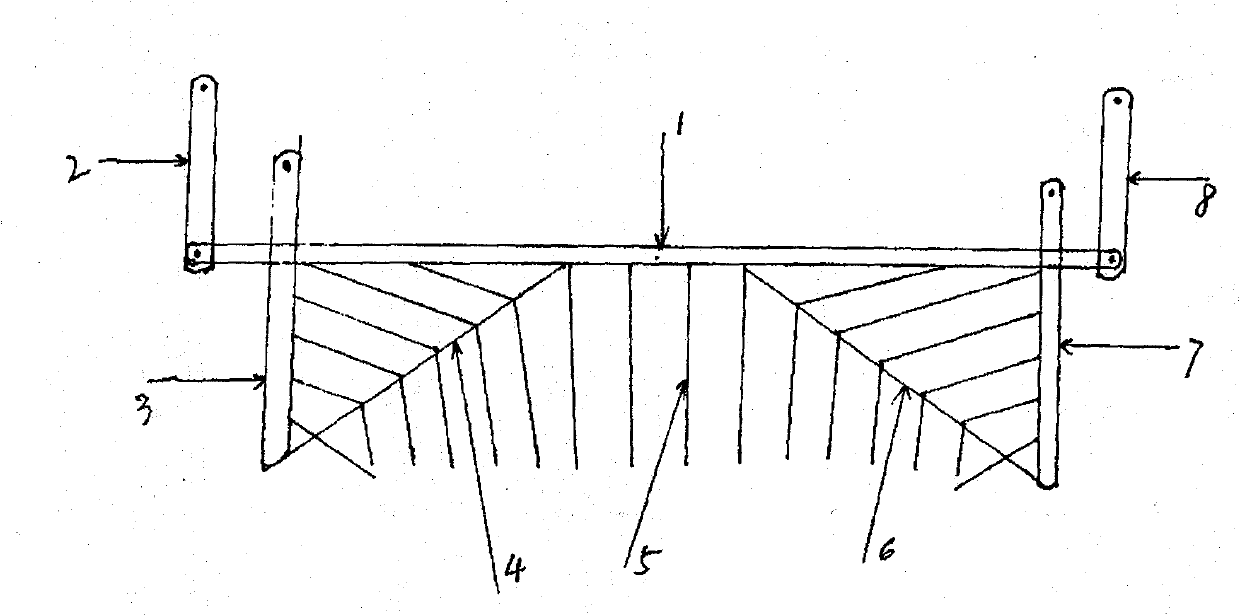

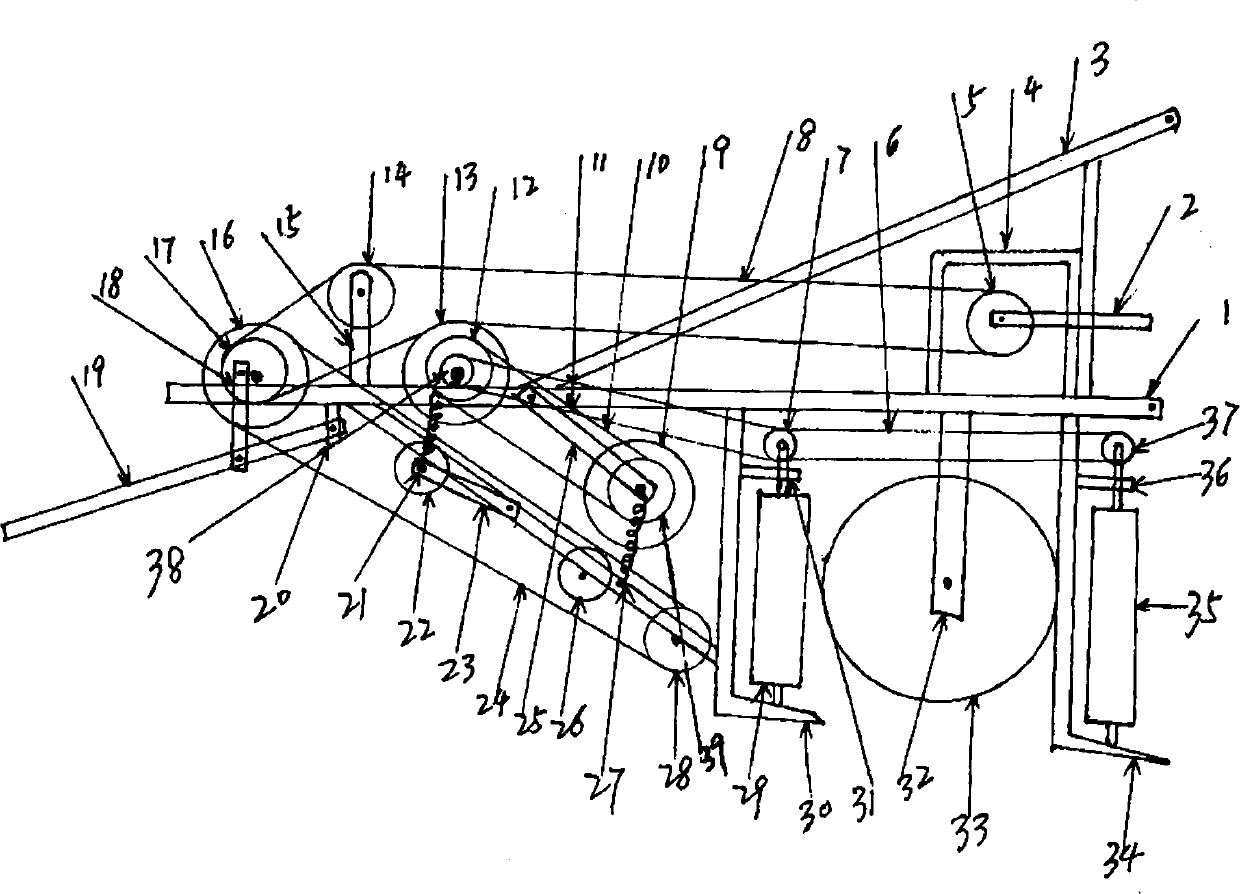

[0011] Such as figure 1 As shown, the new peanut harvester of the present invention is composed of: body frame 3, speed change gear box 4, front digging shovel 34, front anti-blocking drum 35, crushed soil roll 33, rear seedling picking shovel 30, rear defense Blocking cylinder 29, transporting seedling leaking earth chain 24, front to rolling 9, front supporting chain to rolling device 26, back to rolling 13, back supporting chain to rolling device 21 and lever type to form seedling removal soil-forming device. The reversing gear box 4 is located at the front middle part of the body frame 3, and the chain gear 5 installed on it is connected with the chain gear 17 on the sprocket 16 for transporting seedlings and leaking soil through the transmission chain 8 and the rear pair of rollers 13; The two ends of sprocket gear 16 axles are installed on the both sides above the body frame 3 rear portion, and it passes seedling transporting earth leakage chain 24 and is fixed on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com