PTC heating device and control method thereof

A technology of a heating device and a control method, which is applied in the direction of using feedback control, ohmic resistance heating components, etc., can solve the problems of high power consumption, consumption, and inability to adjust power according to needs, so as to achieve flexible operation, reduce power consumption, and improve room The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

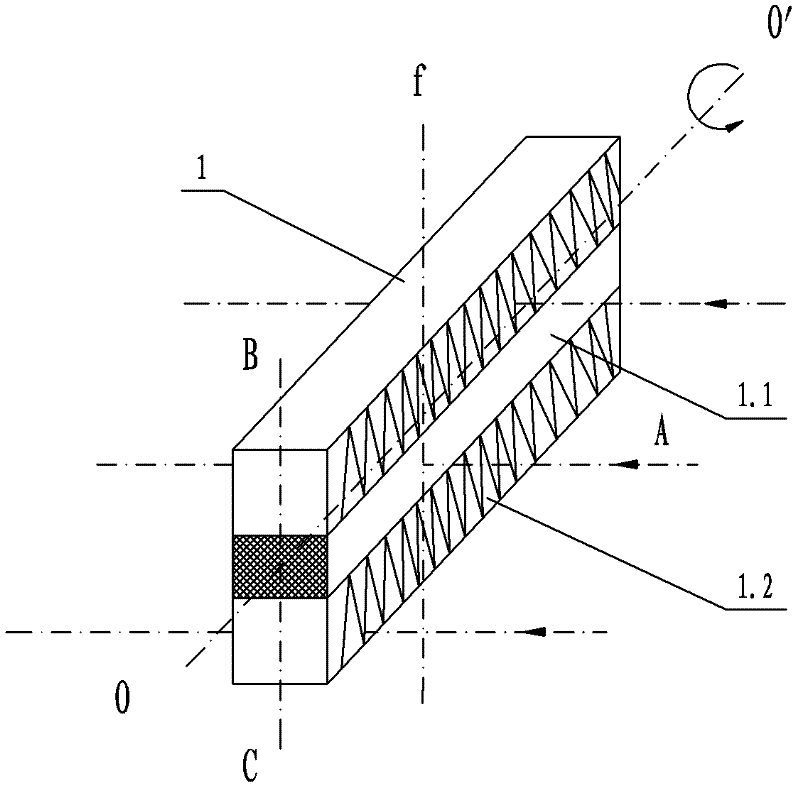

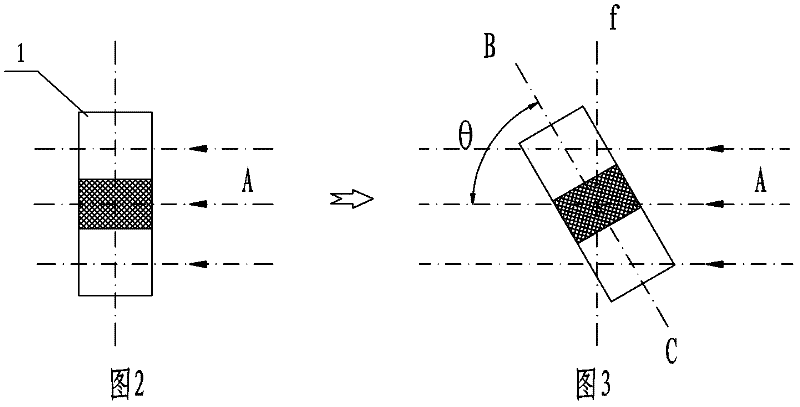

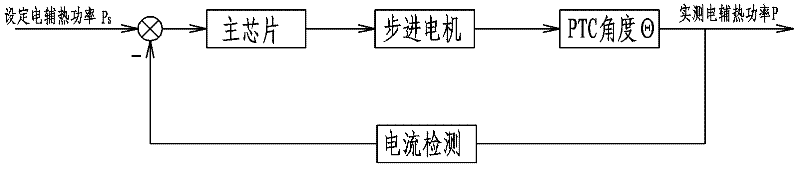

[0026] see Figure 1-Figure 5 , the PTC heating device includes a PTC electric heater 1, a stepper motor and a drive mechanism for driving the PTC electric heater 1 to rotate around its axis, a current transformer for detecting the loop current of the PTC electric heater 1, and a circuit transformer with a calculation , comparison and control functions of the main chip, the main chip is connected with the current transformer and the stepping motor respectively. Among them, the main chip is the controller, the current transformer is the detection conversion element, and the PTC electric heater is the controlled object.

[0027] The control method of the PTC heating device comprises the following steps:

[0028] In the first step, the user sets the required electric auxiliary heating power value Ps through the main chip;

[0029] The second step is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com